Assembly, Operation – MTD TMO-285A User Manual

Page 2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

I FRONT DRAW BAR

ASSEMBLY

ASSEMBLY

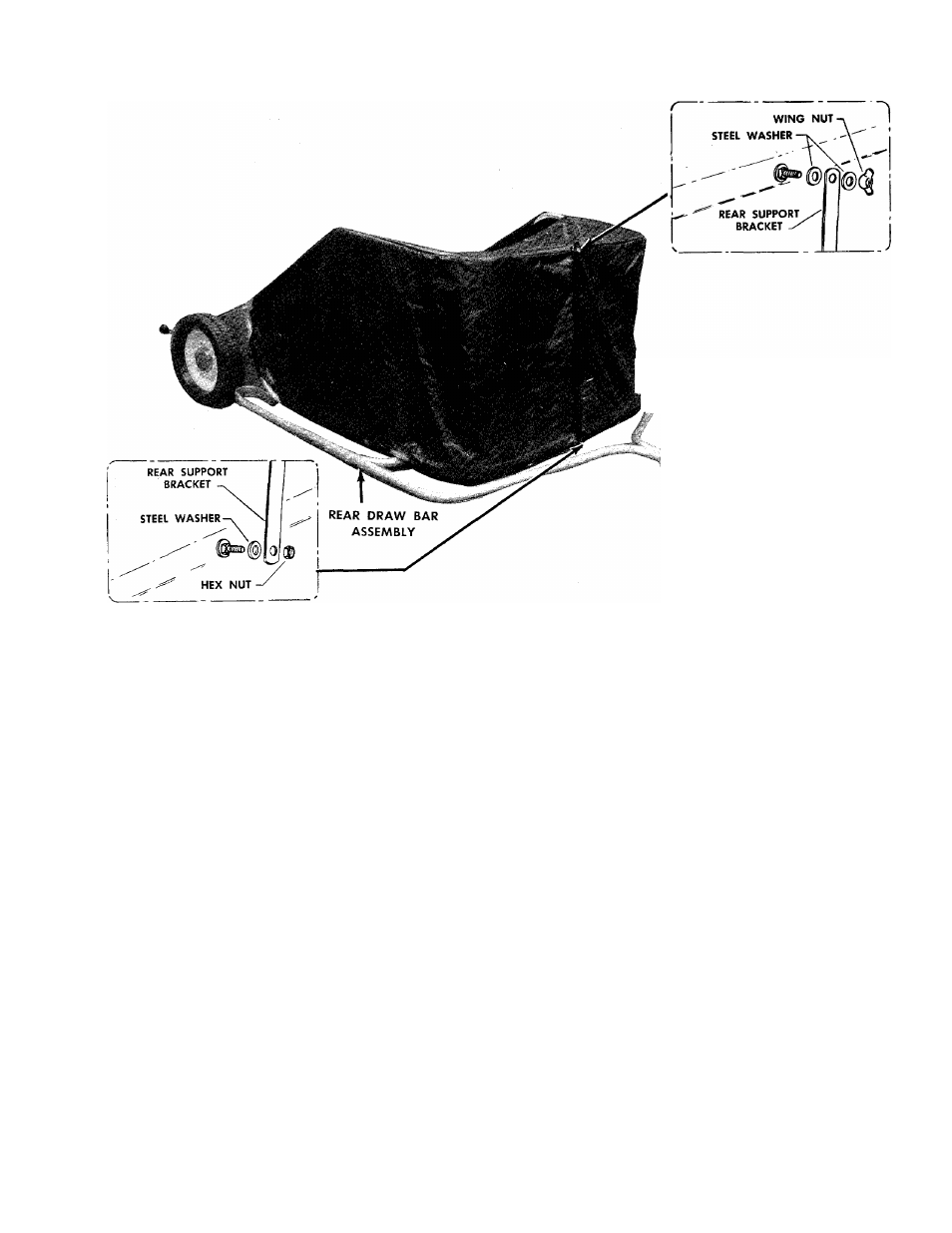

Your Two-Stage Sweeper has been assembled at

the factory except for the Front Draw Bar

Assembly and the Hopper which has been

shipped in the storage position.

To assemble, slide the Front Draw Bar onto the

Rear Draw Bar as shown and fasten securely with

nuts and bolts provided. To prepare the Hopper

for operation, remove the Rear Support Bracket

from the underside of the Hopper, and assemble

to the Lower Mounting Bolt of the Hopper as

shown above. Lift the Upper Frame and assemble

the other end of the support to the Top Mounting

Bolt as shown;

For Storage—The Hopper can be collapsed by

removing the support from the Top Mounting

Bolt only, allowing the Hopper and support to fold

down to the storage position.

OPERATION

Your Sweeper is a precision piece of equipment.

Engineering skill and experience have been

combined to provide the ultimate in safety and

efficiency. However, as with any type of precision

equipment, carelessness or error on the part of

the operator can result in damage to your

equipment. Therefore, exercise caution at all

times and do not subject your sweeper to misuse.

SWEEPING SPEED

Your sweeper has been designed to operate at

approximately

AVz

mph which is a fast walk and in

the middle of the range of most riding mower

speeds. Varying conditions may dictate another

speed and therefore, it is recommended you try

sweeping at different speeds to find the one most

suited to your conditions.

BRUSH HEIGHT ADJUSTMENT

To adjust your unit to the best operating height

adjustment, press the adjust lever in an outward

direction until the trunnion on the adjust lever

clears the end plate.

Move the lever UP for greater clearance between

lawn and brush or down for less clearance. After

the desired clearance is obtained allow the adjust

lever to spring back locking the trunnion in the

proper positioning hole.

Follow the same procedure for the opposite

wheel. See figure 1.