MTD 111-902A User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Blade Mounting Torque

3/8" Dia. Bolt 375 in. ib. min., 450 in. lb. max.

5/16" Dia. Boit 150 in. ib. min., 250 in. Ib. max.

To insure safe operation of your unit, ALL nuts

and bolts must be checked periodical ly for correct

tightness.

DECK

The underside of mower deck should be cleaned

after each period of use as grass clippings, leaves,

dirt and other matter will accumulate. This ac

cumulation of grass clippings, etc., is undesirable

as it will invite rust and corrosion and may cause

an uneven discharge of grass clippings at the next

cutting.

The deck may be cleaned by tilting the mower for

ward or on its side and scraping clean with a

suitable tool or by washing with a stream of water

from a garden hose.

CAUTION

Do not direct the stream of water at

a hot engine as damage to the

engine may result.

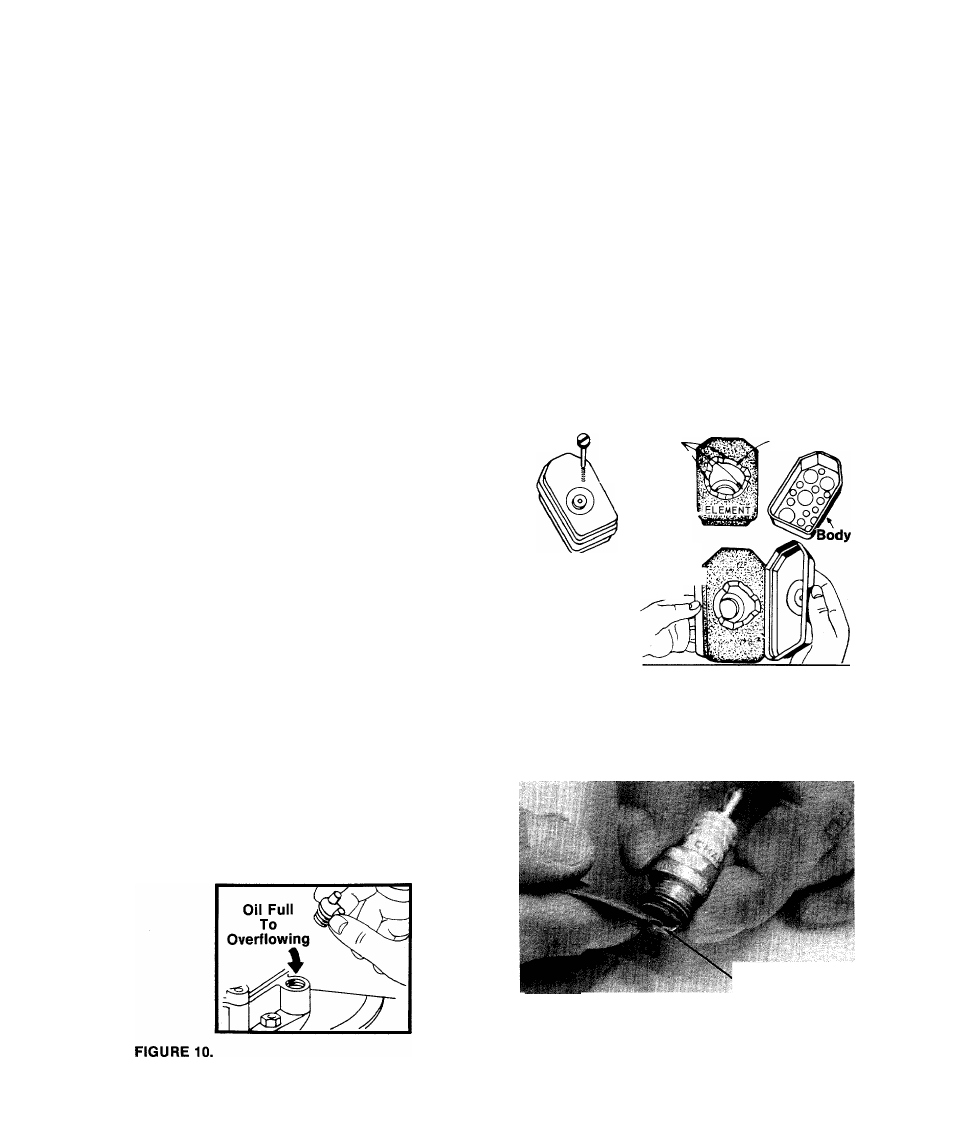

ENGINE OIL

Check oil level before starting engine and after

every 5 hours of operation.

ADD oil as necessary to keep level FULL TO

POINT OF OVERFLOWING.

Before removing oil fill plug, clean area around

plug to prevent dirt from entering oil fill hole.

Engine should be in a level position when check

ing oil.

Change oil after first 5 hours of operation.

Thereafter change every 25 hours. Change oil

while engine is warm. Oil may be drained thru

drain on bottom of engine. To drain completely,

always place engine level when draining thru the

bottom. Oil capacity 1-1/4 pints. See figure 10.

AIR CLEANER

Clean air cleaner and re-oil element every 25 hours

under normal conditions. Clean every few hours

under extremely dusty conditions. Poor engine

performance and flooding usually indicates that

the air cleaner should be serviced. See figure 11.

1. Remove screw.

2. Remove air cleaner carefully to prevent dirt

from entering carburetor.

3. Take air cleaner apart and clean.

a. WASH foam element in kerosene or a liq

uid detergent and water to remove dirt.

b. DRY foam completely by wrapping and

squeezing in a cloth.

c. SOAK foam with engine oil. Squeeze to

distribute and remove excess oil.

4. Reassemble parts and fasten to carburetor.

Screwi

Assemble

One of These^

Low Points

Towards

Narrow

Edge of

Element

Assemble Element So

Lip Extends Over Edge,4

of Air Cleaner Body.

Lip Will Form

Protective Seal

When Cover Is

Assembled

Cup

CLEAN AIR CLEANER

FIGURE 11.

Clean

Electrode

FIGURE 12.