Chain maintenance • sharpen the chain when, B. sharpening instructions, ) sharpen cutters – Poulan 3400 User Manual

Page 16: Zl warning, ) correct depth gauges, B. starting instructions, A. guide bar and chain

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

A. GUIDE BAR AND CHAIN

Increase the service life of your Guide Bar and

Chain by:

r

■

—Using the saw properly and as recommended

in this manual.

—Maintaining correct Chain Tension, paged.

—Proper lubrication, page 10.

—Regular maintenance as described in this sec

tion.

1. CHAIN MAINTENANCE

• Sharpen the chain when:

— Wood chips are smdil and powdery.

Wood

chips made by the saw chain should be

about the size of the teeth of the chain.

— Saw has to be forced through the cut.

— Saw cuts to one side.

ICAUTION:

I

Always wear gloves when hand

ling the chain. The chain can be sharp enough to

cut you even though it may be too dull to cut

wood.

a.

CLEAN TREE SAP FROM THE CHAIN

BEFORE IT IS SHARPENED:

1

. ) Soak chain in a petroleum based solvent

or a detergent and water solution

2. ) Dry chain thoroughly.

3. ) Immerse the clean chain In light oil until oil

seeps into the rivet holes.

NOTE:

Do not run a chain which has been

cleaned without lubricating it first.

b.

SHARPENING INSTRUCTIONS

Items required:

Gloves

7/32” dia. file

6

” file holder

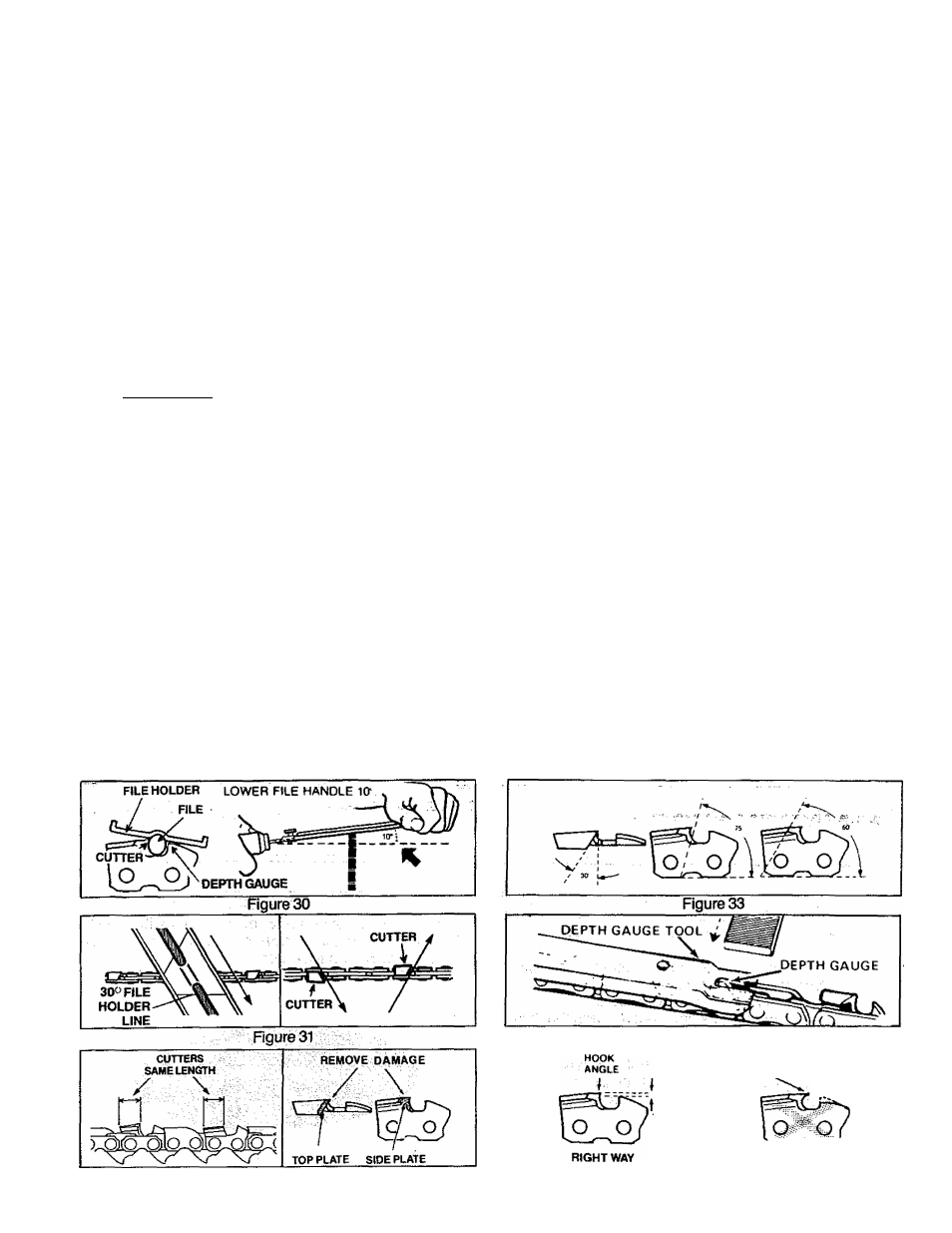

4.) Sharpen cutters.

a. ) Support the square rod on the file holder

(with 7/32" round file) on cutter top plate.

Figure 30.

b. ) Hold the file holder level with the 30° guide

mark paraiieUo the center of the chain

and lower file handje

10

°. Figure 30.

c. y File from inside toward outside of cutter,

straight across, on forward stroke only. Use

2 or 3 strokes per cutting edge. Figure 31.

d. ) Keep all cutters the same length. Figure

32.

e. ) File enough to remove any damage to cut

ting edge(side &top plate) of cutter. Figure

32.

f. ) Fite P72S chain to meet specifications

shown in Figure 33.

ZL WARNING

Maintain the proper hook angle according to the

manufacturer’s specification for the chain you are

using. Too much hook angle will increase the chance

of kickback which can result in serious personal

injury. Figure 33 & 35.

5.) Correct Depth Gauges

a. ) Place depth gauge tool over each cutter

depth gauge. Figure 34.

b. ) File level with the flat file If depth gauge is

higher than the depth gauge tool.

c. ) Maintain rounded front corner of depth

gauge with a flat file. Figure 34& 35.

NOTE: The very top of the depth gauge

should be flat with the front half rounded

off with a flat file.

Depth Gauge Tool

Flat file

Vise

WARNING

Depth gauge tool is required to insure proper depth

gauge. Filing the depth gauge too deep will increase

the chance of kickback which can result in serious

personal injury.

Figure 34

16

Figure 32

TOO MUCH

SQUARED

HOOK ANGLE

qf

F CORNER

\

ROUNDED

CORNER

WRONG WAY

Figure 35