Generator air flow, Cooling air inlet openings, Generator air flow cooling air inlet openings -20 – Generac Power Systems 0661-5 User Manual

Page 21: Cooling and ventilating air

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

COOLING AND VENTILATING AIR

It is absolutely essential that an adequate flow of air

for cooling, ventilating and engine combustion be sup

plied to the generator set. Without sufficient air flow,

the engine-generator quickly overheats. Such over

heating can cause serious operating difficulties and

may also cause fire and personal injury. The installer

must make sure that sufficient air is available to the

generator for cooling, ventilating and combustion. The

installer must also provide for a path for exhausting

the cooling air to the exterior of a compartment, if so

equipped.

DANGER: Never use discharged cooling air for

heating or permit such air to enter the vehicle inte

rior. This air contains deadly carbon monoxide

gas and other poisonous, flammable or explosive

gases.

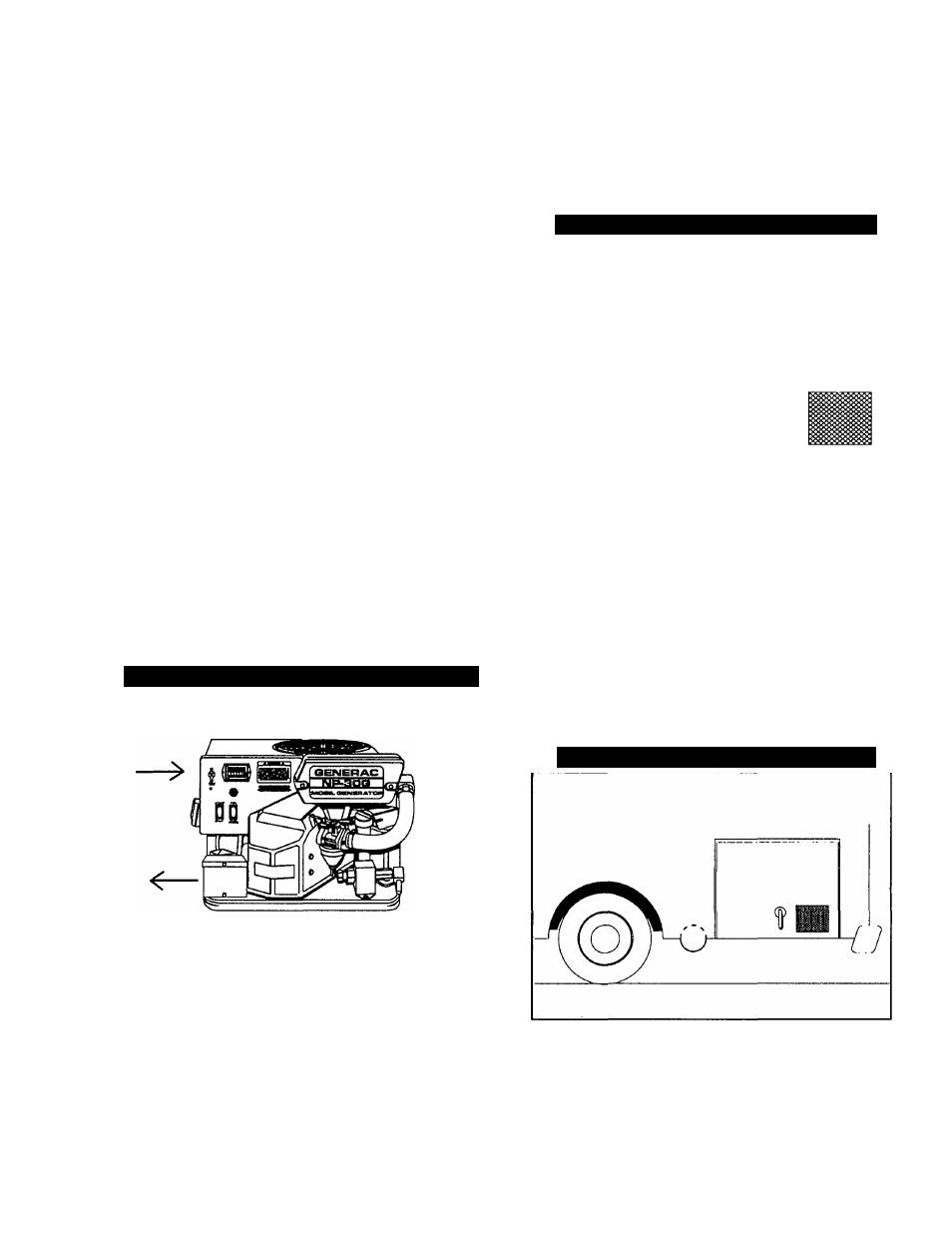

GENERATOR AIR FLOW

Engine operation drives cooling fans for the 2-stage

cooling air system. A pressure fan draws cooling air

into the top of generator and into the side of the con

trol panel (Figure 20). This air flow cools the engine-

generator and electronic components. The second

part of cooling system, a suction fan, draws air that is

heated from a hot engine into a collector pan at the

base of the unit. This heated air (although cooler than

exhaust muffler) is directed across the muffler to cool

it. The heated air flow is then deflected out the bottom

toward the ground.

Figure 20 — Air Flow Through Engine-Generator

COOLING AIR INLET OPENINGS

Ideally, you should provide three air inlet openings,

whether the generator is housed in a conventional

compartment or not. Two of the openings should be

10 square inches and located as shown in Figure 21.

The third opening should provide for a minimum of 40

square inches unrestricted and be located lower on

the compartment door.

NOTE: Screening, louvers, or expanded metal that

cover air openings restrict air flow that you must com

pensate for by making the actual air opening propor

tionately larger. See “Compensating for Restrictions.”

Figure 21 — Air Inlet in Compartment Door

10 SQUARE INCHES

(OPTIONAL OPENINGS)

40 SQUARE INCHES UNRESTRICTED

(MINIMUM OPENING)

For conventional compartment mounted units, the air

inlet is generally provided in the compartment door.

IMPORTANT: IF YOU PLAN TO INSTALL THE GEN

ERATOR IN A COMPARTMENT, BE SURE TO

LEAVE AT LEAST ONE (V) INCH OF CLEARANCE

BETWEEN THE GENERATOR AND COMPART

MENT WALLS AND CEILING. INCLUDE 26 GAUGE

GALVANIZED STEEL LINING AND SOUND INSULA

TION WHEN YOU MEASURE FOR THIS 1 INCH

CLEARANCE.

When the unit is installed on a suspended mounting

system, one of several different methods of supplying

air flow may be used as follows:

• Provide a door in the vehicle skirt having an air inlet

opening (Figure 22).

Figure 22 — Suspended Mount; Inlet Door

19 —