Engine spark plug, Fuel filter, Cleaning the generator – Generac Power Systems 0661-5 User Manual

Page 12: Service and adjustments ■ engine speed, Engine spark plug fuel filter, Clean air intake screen

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CLEAN AIR INTAKE SCREEN

Clean all foreign material from the air intake screen

(Figure 6) at lease once every 100 hours of operation.

Clean more often if necessary.

Inspect the area around the generator exhaust muffler

periodically and remove all grass, leaves, dirt, etc.

from this area.

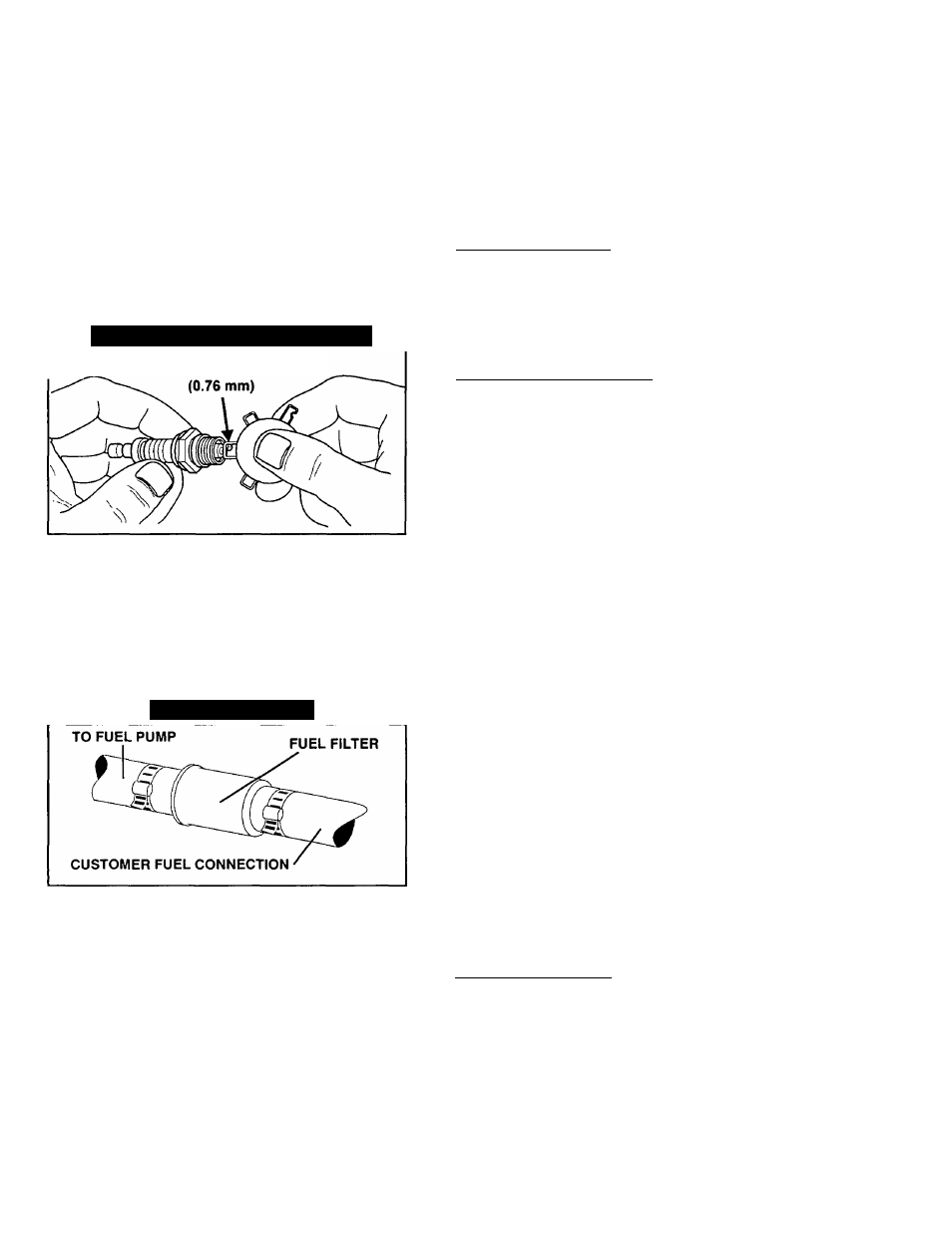

ENGINE SPARK PLUG

Clean or replace engine spark plug and set gap to

0.030 inch (0.76mm) every 100 hours of operation

(Figure 6). Clean by scraping or wire brushing and

washing with commercial solvent. DO NOT BLAST

CLEAN SPARK PLUG.

Figure 6 — Setting Gap on Spark Plug

SET PLUG GAP AT 0.030 inch

CAUTION: Sparking can occur if wire terminal

does not fit firmly over spark plug terminal end. If

necessary, reform wire terminal to obtain a tight fit.

FUEL FILTER

Remove and replace fuel filter (Figure 7) every 100

hours of operation or once each year, whichever

occurs first.

Figure 7 — Fuel Filter

CLEANING THE GENERATOR

Keep your generator set as clean and dry as possible.

Dirt and moisture that are permitted to accumulate on

electrical windings have an adverse affect on the

insulation resistance of those windings.

Moisture that is allowed to remain in contact with

windings will be retained in voids and cracks of the

windings. Dirt makes the problem worse, since it

tends to hold the moisture into contact with the wind

ings. Salt, as from sea air, worsens the problem since

it tends to absorb moisture from the air. The combina

tion of salt and moisture makes a good electrical con

ductor.

CAUTION! Do NOT use a forceful spray of water to

clean the generator. Water will enter the generator

interior and cause problems, and may also conta

minate the generator fuel system.

BAHERY

All lead-acid storage batteries will discharge when not

in use. Inspect the generator battery as follows:

■ ONCE WEEKLY______________________

Inspect battery posts and cables for tightness, corro

sion. Clean and/or tighten as necessary.

Also check battery fluid level, and, if necessary, fill

with DISTILLED WATER ONLY. DO NOT USE TAP

WATER IN BATTERY.

■ EVERY SIX MONTHS__________________

Have the battery state of charge and condition

checked by an automotive service facility. This should

be done with an automotive type battery hydrometer.

DANGER: Storage batteries give off explosive

hydrogen gas. This gas can form an explosive

mixture aroung the battery for several hours after

cahrging. The slightest spark can ignite gas and

cause an explosion. Such an explosion can shat

ter the battery and cause blindness or other injury.

Any area that houses a storage battery must be

properly ventilated. Do not allow smoking, open

fiame, spards or any spark producing tools or

equipment near the battery.

DANGER: Battery electrolyte fluid is an extremely

caustic sulfuric acid solution that can cause

severe burns. Do not permit fluid to contact eyes,

skin, clothing, painted surfaces, etc. Wear protec

tive goggles, protective clothing and gloves when

handling a battery. If you spill the fluid, flush the

affected area immediately with clear water.

DANGER: Do not use any jumper cables or boost

er battery to crank and start the generator engine.

If any battery has discharged, remove it from the

vehicle for recharging.

SERVICE AND ADJUSTMENTS

■ ENGINE SPEED____________________

Engine speed is completely computer-controlled.

There is no adjustment for speed on the unit. The

computer adjusts the engine speed using an electron

ic governor throttle control. The computer monitors

the demand for power and adjusts the engine speed

accordingly. This allows the engine to produce only

the power required, resulting in fuel economy as well

as lowering the overall noise emitted.

— 10 —