Screw on ^ engine, I warning, Carburetor adjustments (see figure 4.) – MTD 110-530A User Manual

Page 7: Initiai adjustment, Final adjustment, Lubrication, Important

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Throttle

Control Wire

Screw On ^

Engine

FIGURE 3.

I WARNING {

If any adjustments are made to the

engine while the engine is running

(e.g.

carburetor),

disengage

all

clutches and blades. Keep clear of

all moving parts and be careful of

heated surfaces and muffler.

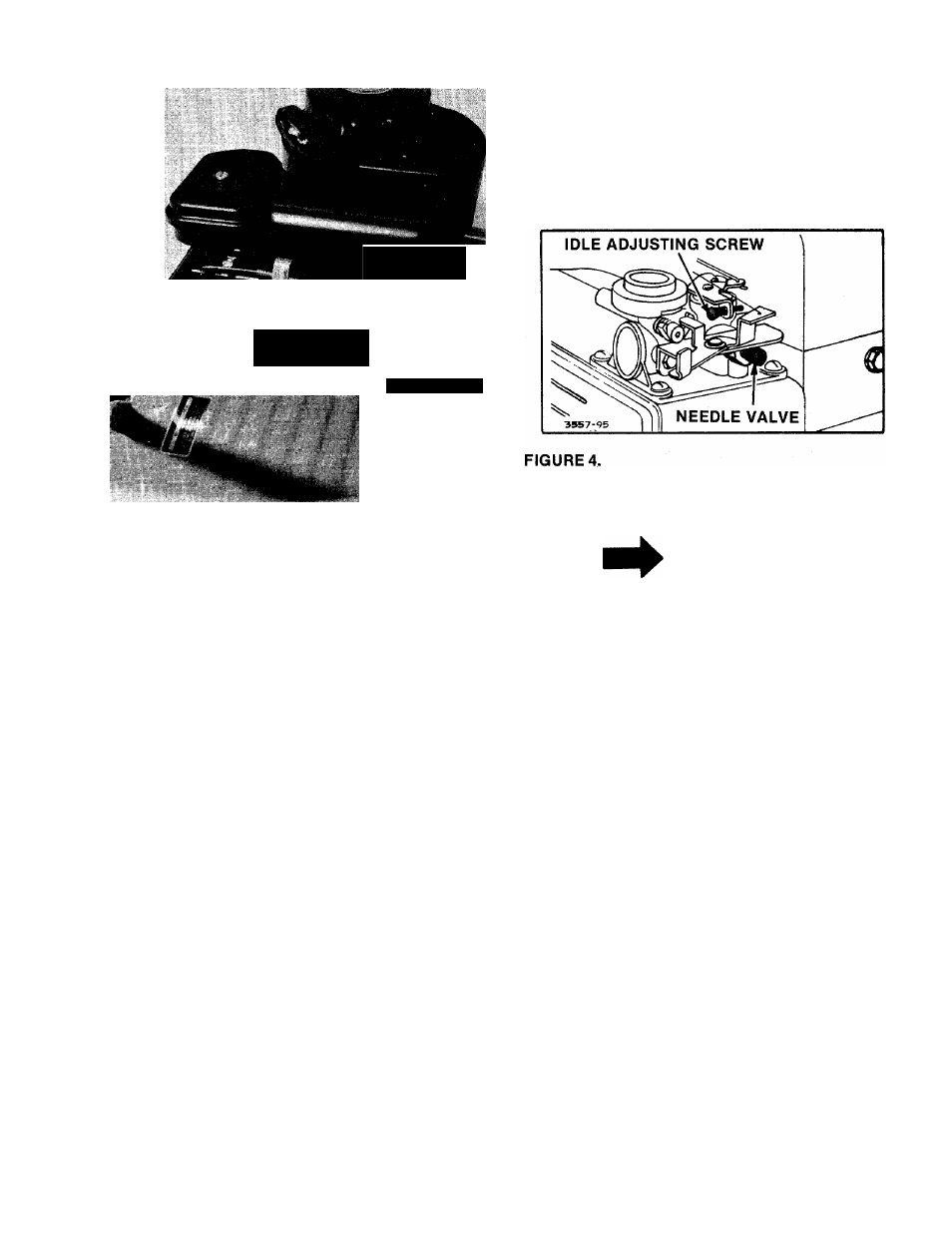

CARBURETOR ADJUSTMENTS (See figure 4.)

Minor carburetor adjustment may be required to

compensate for differences in fuel, temperature,

altitude and load.

Initiai Adjustment:

Turn needle valve clockwise to close it. Then open

2 turns. This initial adjustment will permit the

engine to be started and warmed up before mak

ing final adjustment.

Final Adjustment:

With engine running at normal operating speed

(approximately 3000 RPM without load), turn nee

dle valve clockwise until engine starts to lose

speed (lean mixture). Then slowly turn needle

valve

counterclockwise

past

the

point

of

smoothest operation, until engine just begins to

run unevenly. This mixture will give best perfor

mance under load.

To check adjustment, move engine control from

SLOW to FAST speed. If engine tends to stall or

die out, it usually indicates that the mixture is

slightly lean. It may be necessary to open the nee

dle valve slightly to provide a richer mixture. This

richer mixture may cause a slight unevenness in

idling.

LUBRICATION

IMPORTANT

Always stop engine and disconnect

spark

plug

wire

before

cleaning,

lubricating or doing any kind of work

on lawn mower.

Wheels—

Unit

is

provided

with

ball

bearing

wheels. Lubricate at least once a season with light

oil.

Protective Shield—

The pivot points on the protec

tive shield should be lubricated periodically with

light oil to prevent any rust or binding.

Chute Deflector—

The torsion spring and pivot

point should be lubricated periodically with light

oil to prevent any rust or binding. Deflector must

work freely.

Engine—

Follow engine manaul for lubrication in

structions. Check oil level before each use.

Throttle—

Periodically

lubricate

throttle

control

lever and throttle wire assembly with a few drops

of light oil (SAE No. 10 or 20) for ease of operation.

Friction

point

between

idler

bracket

assembly

(Ref. No. 18 on page 16) and deck should be greas

ed once each season with a multi-purpose grease.

Blade

Spindle

Assembly—

The

blade

spindle

assembly is equipped with a grease fitting. Use

grass discharge chute for access to the fitting

located under the deck. Use multi-purpose grease.

Lubricate PRIOR to initial use and every 25 hours

thereafter.