General rotary tiller operation, Lubrication – MTD 192-766 User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

1. Before attaching your rotary tiller to your tractor, be

sure the rear wheels on the tractor are all the way

into the minimum rear wheel width. Refer to your

tractor manual.

2. Remove the draw bar assembly from the three point

hitch of your tractor by removing the two cotter-

hairpins.

3.

Place the rotary tiller behind the tractor in the

approximate position shown in Fig. 2.

4. Attach universal drive shaft (Ref. 26) to the tractor

power take off. Tighten set screw (Ref. 27).

5. Move the lift lever on the tractor until the draft bar

assemblies line up with pivot brackets (Ref. 24).

6. Assemble pivot brackets (Ref. 24) to the rear of the

tractor with washers and cotter-hairpins.

ATTACHING YOUR ROTARY TILLER TO YOUR

TRACTOR (Model 192-766).

1. Before attaching your rotary tiller to your tractor, be

sure the rear wheels on the tractor are all the way

into the minimum rear wheel width. Refer to your

tractor manual.

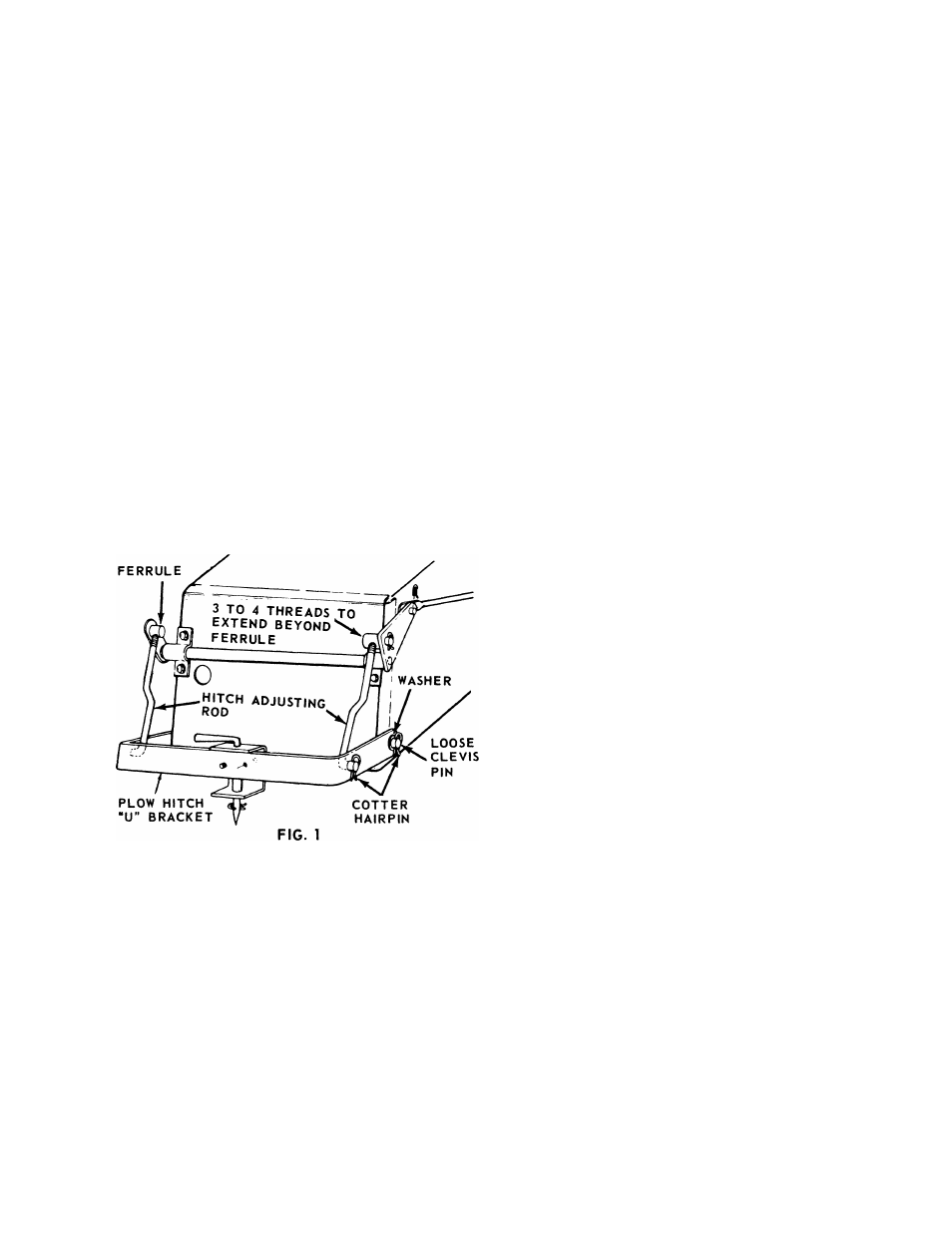

Remove the

part of the plow hitch from your

tractor by removing the two cotter-hairpins on the

loose clevis pins and the two cotter-hairpins from

the hitch adjusting rods. Refer to Fig. 1.

ATTACHING YOUR ROTARY TILLER TO YOUR

TRACTOR (Models 193-966 and 193-967)

2

.

3. Adjust the hitch adjusting rods until 3 or 4 threads

extend beyond the rear hitch ferrule.

4.

Place the rotary tiller behind the tractor in the

approximate position shown in Fig. 2.

5. Attach universal drive shaft (Ref. 26) to the tractor

power take off. Tighten set screw (Ref. 27).

6. Assemble brackets (Ref. 68 & 69) to the rear of the

tractor with the loose clevis pins, washers and

cotter-hairpins.

CHECK LUBRICANT LEVEL at this time. The gear

case is lubricated at the factory but should be checked

for proper lubricant level before each operation. Remove

plug (Ref. 61) on side of gear case. Lubricant should

be at this level, if not, fill through the vented pipe plug

hole (Ref. 21) with SAE 140 oil until the lubricant over

flows through the hole in the side of the gear case.

Replace the pipe plugs. BE SURE THE VENTED PIPE

PLUG IS IN THE OIL FILL HOLE. Refer to Fig. 3.

Lift the rotary tiller with the lift h^^adle on the tractor

to transport it to and from the work area. Use caution

when transporting the rotary tiller since your ground

clearance has been reduced.

The entire tiller unit is offset to the left to allow

closer tilling with the left side.

NOTE:

BE SURE THE POWER TAKE OFF HANDLE

IS IN THE ‘‘OFF” POSITION BEFORE STARTING

THE TRACTOR ENGINE. Refer to the tractor manual

for proper position of the PTO handle.

GENERAL ROTARY TILLER OPERATION

ALWAYS shut the engine off when removing a stone or

anything that becomes entangled in the tines.

All large stones or rocks should be removed from the

area before you begin tilling.

Tilling can be done with or w i t h o u t the outer tine

assemblies. You can till 32!/2” wide with the outer tines

and 17” wide with only the inner tines.

Use rear wheel weights when tilling. Part n u m b e r

191-776.

Maximum tilling depth is approximately 10” depending

on the type of soil. This CANNOT be accomplished in

one pass. Maximum tilling depth may be only 2-1/2”

on extremely hard soil on the first pass.

The more passes you make with the tiller over the same

area, the deeper you can till and the finer you pulverize

the soil. Change directions as often as you can to level

out the ground and to prevent furrows.

When tilling, the tiller will push the t r a c t o r and the

transmission on the tractor will hold the tractor back.

For easy lifting of the rotary tiller from the ground, shut

off the power by disengaging the PTO h a n d l e and

continue to drive the tractor forward. The tines will

climb out of the hole w h e n you pull the lift l e v e r

handle back.

LUBRICATION

Gear Case

- Lubricated with three quarts of SAE 140

oil. It is lubricated at the factory. Be sure to check

the lubricant level before each use.

To check the oil level, remove plug (Ref. 61) on the

side of the gear case. See Fig. 3. Lubricant should be

at this level. If not, fill through the vented pipe plug

hole (Ref. 21) until it overflows through the hole in

the side of the gear case. Replace both plugs. BE

SURE THE VENTED PIPE PLUG IS IN THE OIL

FILL HOLE.

Grease Fittings

— There are three grease fittings on

the

universal

drive

shaft

assembly.

Lubricate

after

each 25 hours of use with an automotive multi-purpose

type grease. Apply grease with grease gun provided

with your tractor. Lubricate until the old grease is

pushed through and clean grease appears.