D. starter rope, E. oil pump – Poulan 425 User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

D. STARTER ROPE

• Replace a broken starter or a rope that is

badly frayed.

NOTE: A recoil spring lies beneath the pulley and

is under tension. If the recoil spring is dis-

tnrbed, considerable time and effort will be

required to reinstall. For this reason you may

want to let a qualified service dealer handle this

repair. If you try to repair the starter rope and the

recoil spring pops out, take the unit to your dealer.

A

WARNING

Always wear eye protection when servicing the

starter

rope.

The

recoil

spring

beneath

the

pulley is under tension. If the spring pops out,

serious injury can result.

1. Drain the fuel tank.

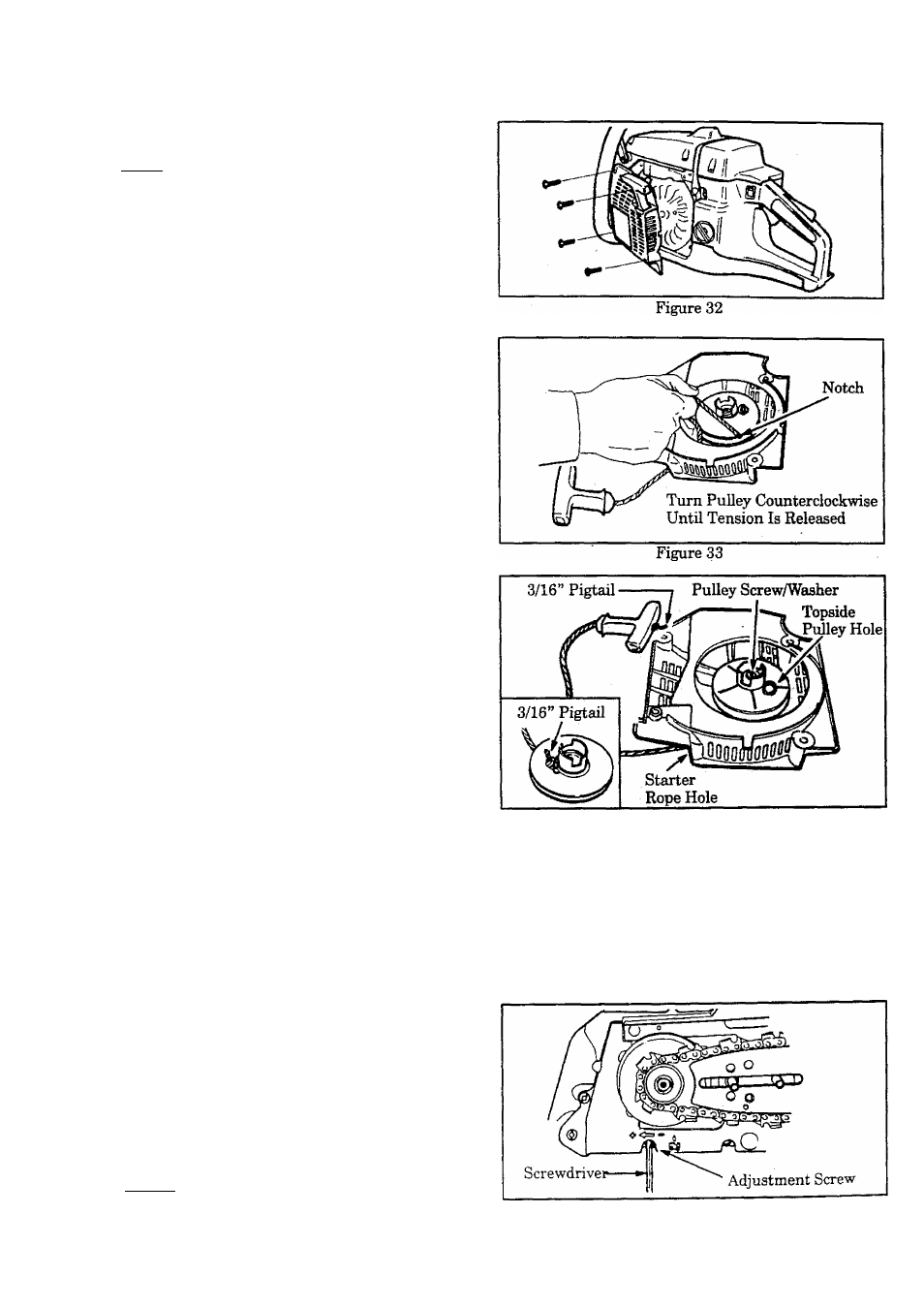

2. Remove the four screws on the side of the fan

housing. Figure 32 .

3. Separate the fan housing from the unit.

4.

If the starter rope is not broken, release the

spring tension by pulling about 10 inches of

rope from the pulley and catch the rope in the

notch as shown in Hgure 33 .

5.

Turn the pulley counterclockwise until the

spring tension is released.

6. Remove the pulley screw/washer in the center

of the pulley. Figure 34

7. Lift the pulley

carefully

while gently twisting it

counterclocl^se.

Remove

any

remaining

rope.

8. Move away from the fuel tank and melt both

ends of the new rope.

9. Allow each melted end to drip once. Then,

while the rope is still hot, pull each melted end

through a rag to obtain smooth, pointed ends.

10. Feed the rope through the hole in the handle.

Secure the rope with a knot, leaving about a

3/16” pigtail. Figure 34 .

11. Feed the rope through the round starter rope

hole in the fan housing. Figure 34.

12. Guide the rope inside the pulley, then up

through the pulley hole to the outside. Fig

ure 34 . Secure the rope with a knot, leaving

about a 3/16” pigtail, ^gure 34 (inset).

13. Rewind the rope onto the pulley by turning the

pulley in a counterclockwise direction.

14. Set the pulley into the housing; push it down

and engage the spring.

15. Replace and tighten the pulley screw/washer.

Figure 34

16. Pull out (inside the pulley housing) 10 inches

of rope and catch the rope in the notch in the

pulley. Figure 33.

17. Turn the puHey 2 complete turns clockwise

winding up the spring.

18. Hold the pulley and pull the sterter rope to the

full extent. Let the rope rewind slowly.

19. Reinstall fan housing.

E. OIL PUMP

The oil flow can be varied by turning the adjustment

screw on the crankcase. Figure 35 .

1. Turn the adjustment screw counterclockwise

(to +) to increase the oil supply.

2. Turn the adjustment screw clockwise (to -) to

decrease the oil supply.

NOTE: Never adjust the oil pump when the en

gine is running.

Figure 35

- 1 6