B. guide bar maintenance, G. spark arrestor, Brmngs&safen instructions – Poulan 425 User Manual

Page 15: Ил у пл, General maintenance

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

GENERAL MAINTENANCE

A good maintenance program of regular inspection

and care will increase the service hfe and help to

maintain the safety eind performance of your saw.

• Make all ac(justments or repairs (except car

buretor acljustments) with;

— spark plug wire disconnected,

— engine cool as opposed to a saw that has just

been run.

Check the saw for loose bolts, screws, nuts,

and fittings regularly.

Loose fasteners can

cause an unsafe condition as well as damage to

your saw.

A WARNING

Have all chain saw service performed by a quail-

fled service dealer other than the items listed in

the maintenance section of this manual.

A. CHAIN REPLACEMENT

•

Use only the replacement chain specified

for your saw (see “NOTE” in the Accesso

ry section).

•

Replace the chain when cutters or links

break.

See a qualified service dealer to replace

and

sharpen

individual

cutters

for

matching your chain.

Always have a worn sprocket replaced by

a qualified service dealer when install

ing a new chain to avoid excessive wear

to the chain.

B. GUIDE BAR MAINTENANCE

•

Conditions which can require guide bar

maintenance:

- saw cuts to one side.

- saw has to be forced through a cut.

-

inadequate supply of oil to bar and

chain.

•

Check the condition of the guide bar

each time the chain is sha^ened.

A worn

guide bar will damage the chain and make cut

ting more difficult.

• Replace the guide bar when:

- the groove in the guide bar is worn,

- the guide bar is bent or cracked,

•

Use only the replacement guide bars spe

cified for your saw. Reduced Kickback

guide bars are available (see “NOTE” in

the Accessory section).

•

Remove the guide bar to service.

•

Clean the oil holes at least once after every

five hours of operation.

•

Remove sawdust from the ^de bar groove

periodically with a putty knife or a wire.

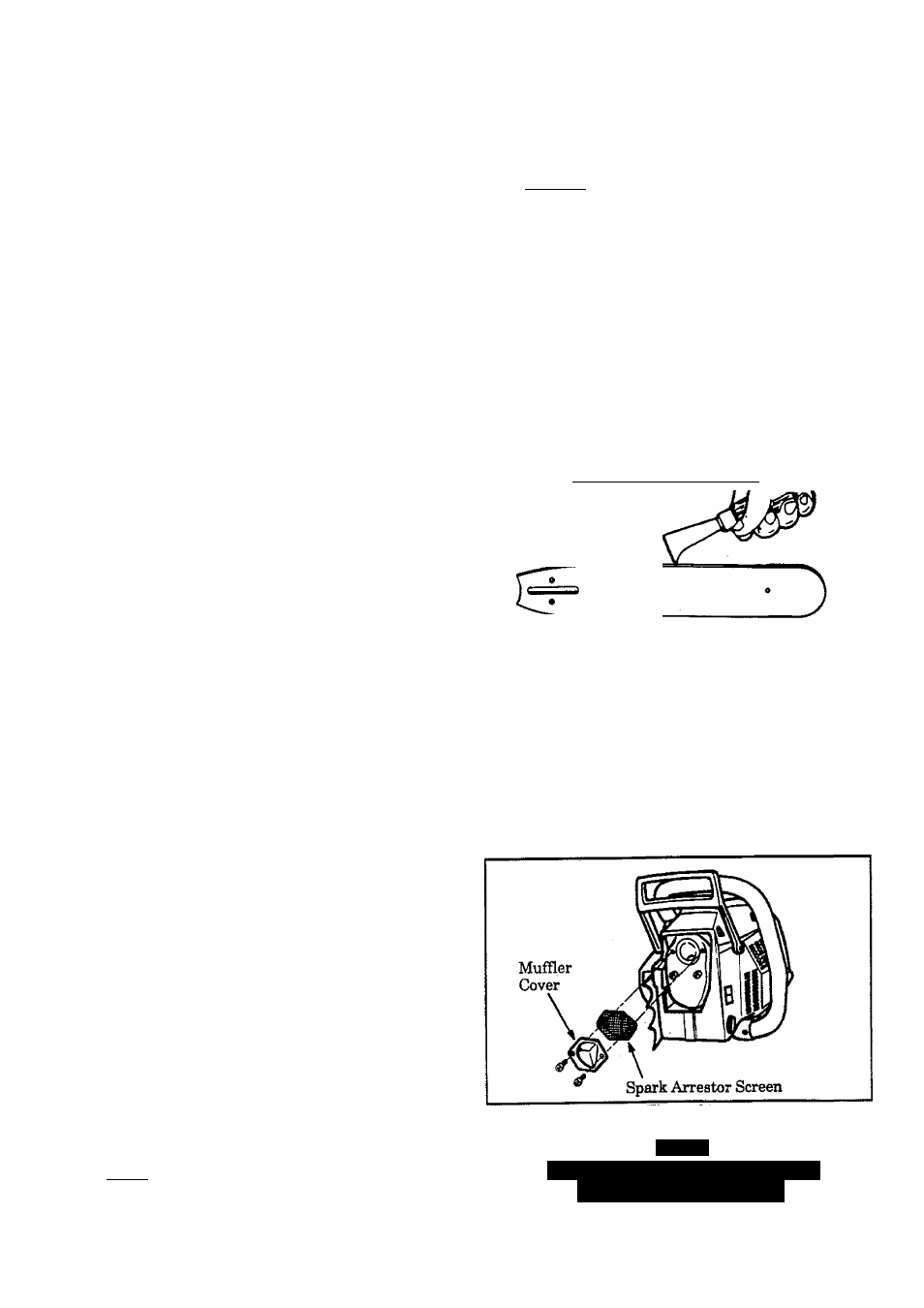

Figure

29.

Remove burrs by filing the side edges of the

guide bar grooves square with a flat file.

Figure 30,

Squeire the edges of an uneven r

2

ul top by

filing with a flat file. Figure 30 .

Remove Sawdust

From Guide Bar

Groove

Figure 29

ИЛ у ПЛ

Correct

Guide Bar

Groove

Worn Grooves

File Edges

Square

Figure 30

G. SPARK ARRESTOR

- • Carbon* deposits build up oh the spark ar

restor

as the saw is used and must be removed to

avoid creating a fire hazard or causing engine

damage.

• Replace the spark arrestor if breaks occur.

• Keep the spark arrestor clean at all times.

Clean:

- as required.

-'at leairt once for each 25—30

hours of operation.

Items required; wire brush, 3/8” wrench

1. Disconnect the spark plug wire.

2. Remove the muffler cover. Figure 31.

3. Remove the screen from the muffler,

4. Clean the screen with a wire brush or replace if

breaks are found,

5. Reassemble parts.

NOTE: Too much oil in the fuel mixture can

cause excessive carbon b\iild-up in the spark ar

restor screen. Use only the correct fuei/oLi ratio as

instructed in the Engine Information section.

Figure 31

HEAD

.BRMNGS&SAFEn INSTRUCTIONS

1*и1:(1УЕХТ1Л;

1 5 -