Engine cleaning, Air cleaner service, Warning – Troy-Bilt 12208 User Manual

Page 23

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Sections: Maintenance

A

WARNING

* n

Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come

to a compiete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition

key on electric start models.

Failure to follow these instructions can result in serious personal injury or property damage.

CHECKING AND ADJUSTING

REVERSE DRIVE BELT TENSION

(Models 12209/12210 only)

Maintaining correct tension on the

reverse drive belt is important to good

performance and long belt life. A loose

belt \will slip on the engine and transmis

sion pulleys and cause the tines and

wheels to slow down - or stop com

pletely - even though the engine is

running at full speed. A loose belt can

also result in premature belt wear.

If there is no reverse action when the

Reverse Clutch Control knob is pulled

out, then the belt tension is too loose.

When checking belt tension, also check

the belt for cracks, cuts or frayed edges

and replace it as soon as possible.

• Check belt tension after the first two

hours of break-in operation (new belt).

• Check belt tension after every 10

operating hours.

To Check Reverse Belt Tension:

1. Be sure that the engine is stopped and

the spark plug wire is disconnected and

moved away from the spark plug.

2. Remove the screw in the plastic belt

cover and slide the cover (which is

attached to the forward clutch cable) out

of the way.

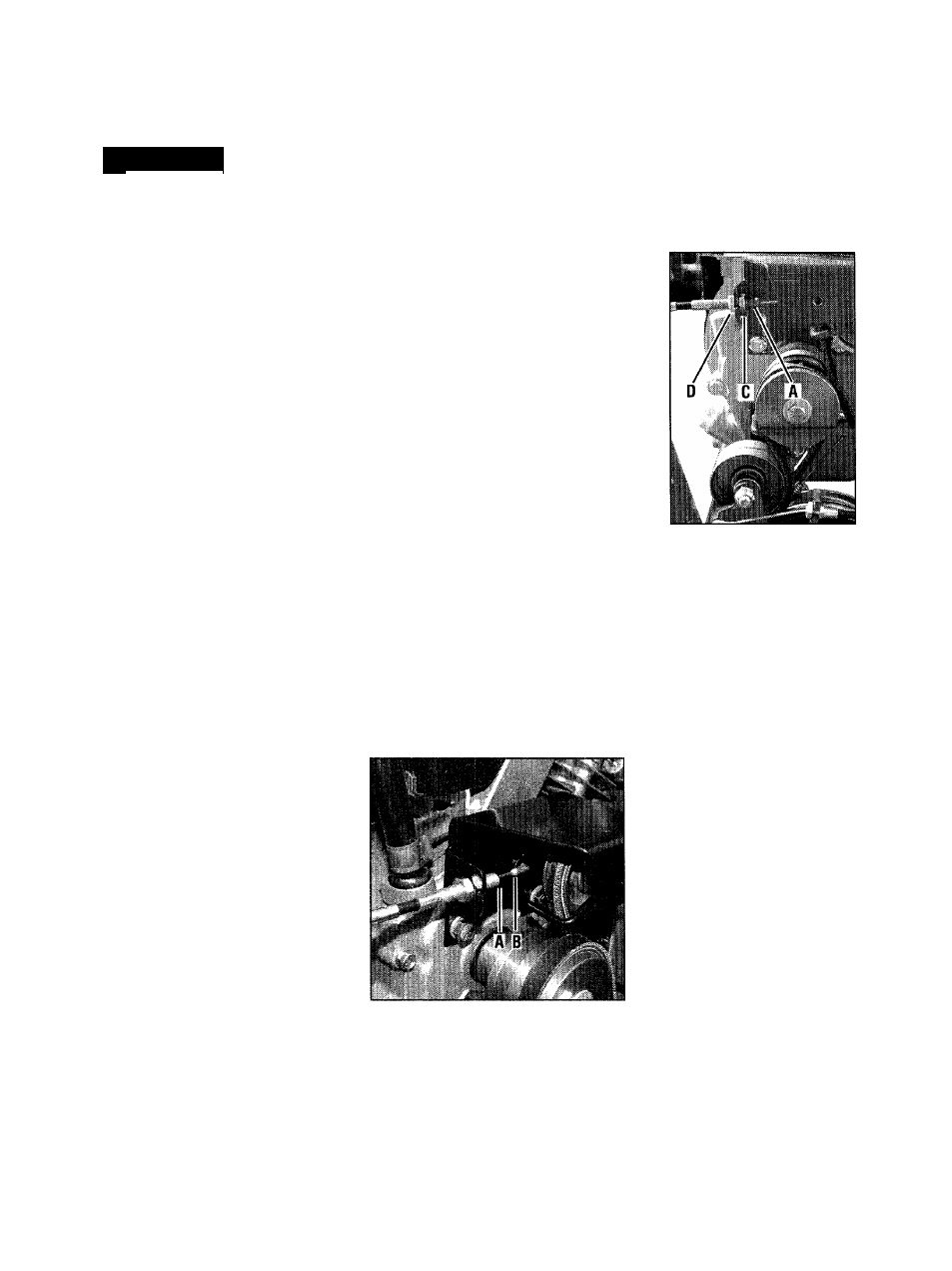

3. Have an assistant pull the Reverse

Clutch Control knob all the way out and

hold it in that position. Measure the

length of the cable wire between the end

of the threaded cable adjuster (A, Figure

5-5) and the end of the Z-fItting (B) to

which the cable wire is attached.

4. The belt tension is ideal if the cable

wire length measures between 1/8" to

1/4". If the length is less than 1/8" (and if

there is no reverse action when the tiller is

running), then make the following adjust

ments. NOTE: If the length is more than

1/4", no adjustment is needed, as long as

the reverse action functions properly.

5. Release the Reverse Clutch Control

knob. Unthread the inner jam nut (C,

Figure 5-6) one to two turns and pull the

threaded cable adjuster (A, Figure 5-6) to

the left until the inner jam nut rests

against the bracket.

6. Prevent the inner jam nut (C) from

turning and tighten the outer jam nut (D)

against the bracket. Prevent the outer

jam nut (D) from turning and tighten the

inner jam nut (C) against the bracket.

7. Measure the gap by repeating Step 3.

Readjust as needed by repeating Steps 5

and 6.

8. Reinstall the belt cover.

Replacement Belt Information

If the drive belt needs to be replaced, see

your local authorized dealer or refer to

the Parts List for ordering information.

Use only a factory-authorized belt as an

“over the counter” belt may not perform

satisfactorily. The procedure requires

average mechanical ability and commonly

available tools.

Figure 5-5: Measure cable wire length to

check for correct reverse belt tension.

Figure 5-6: Move threaded

adjuster (A) to left to increase

belt tension.

ENGINE CLEANING

Keep the engine clean to assure smooth

operation and to prevent damage from

overheating. Refer to the separate Engine

Owner’s Manual for specific repair and

cleaning instructions. All inspections and

services must be done with the engine

shut off and cool to the touch.

AIR CLEANER SERVICE

The engine air cleaner filters dirt and dust

out of the air before it enters the carbure

tor. Operating the engine with a dirty,

clogged air filter can cause poor perfor

mance and damage to the engine. Never

operate the engine without the air cleaner

installed. Inspect and service the air

cleaner more often if operating in very

dusty or dirty conditions.

Service the air cleaner as instructed in the

separate Engine Owner’s Manual.

23