Lubrication – Ariens Sno-Thro PM-32-77 User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

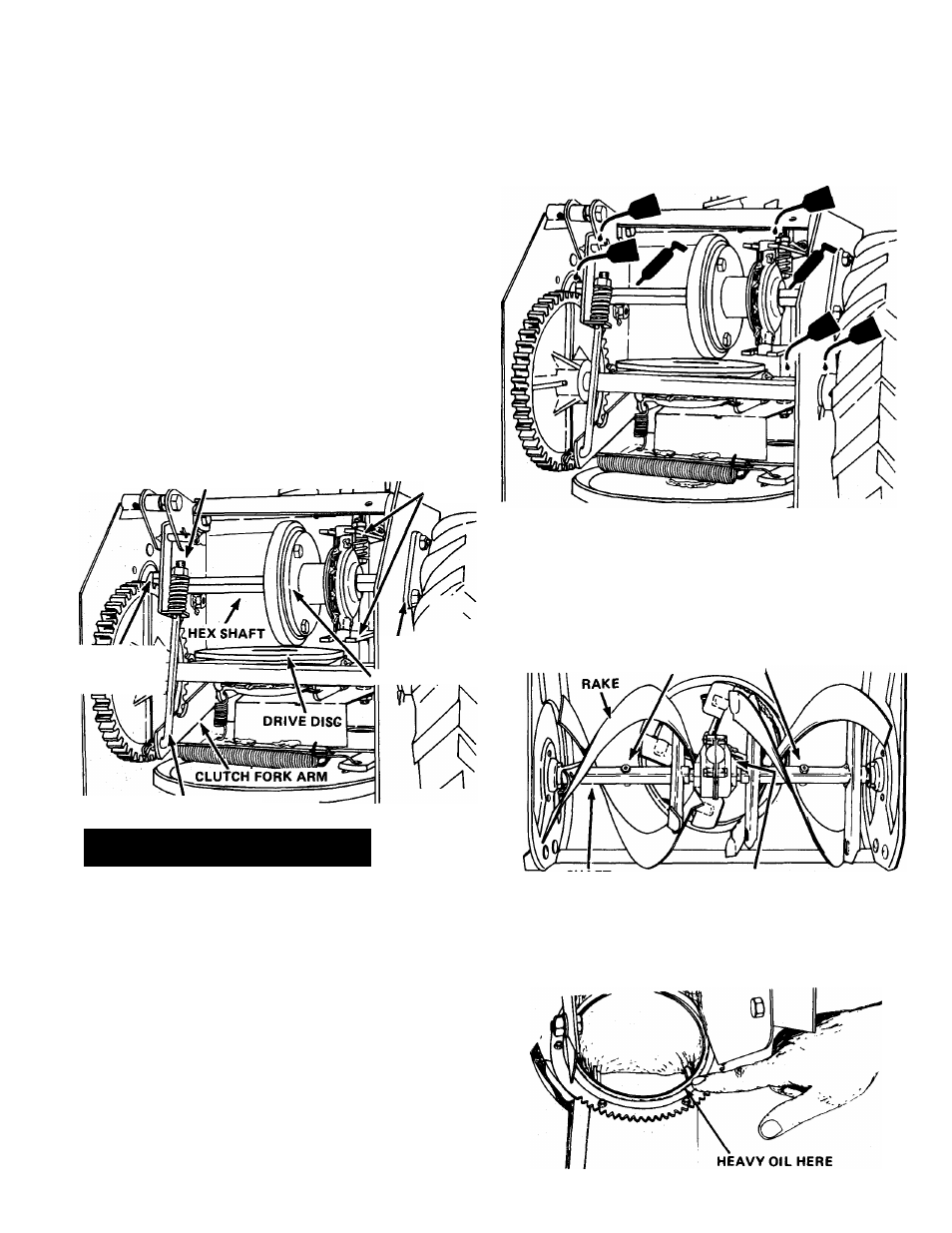

3. Remove the hairpin cotter from the traction clutch rod.

Pull this rod from the clutch fork arm and tip it up and out

of the way.

4. Slide the friction wheel assembly and hex shaft to the right

until the left end of the hex shaft comes free of the left

bearing. Then slip the whole assembly back to the right and

pull it forward out of the frame.

5. With the friction wheel assembly out of the frame, the

three cap screws holding the friction wheel to the hub

may be removed and the friction wheel removed.

6. Position a new friction wheel on the hub and secure with

the three cap screws. Tighten securely.

7. Slip the right end of the complete friction wheel assembly

and hex shaft into the hole in the right side of the frame.

Position the friction wheel hub in the forks. Slide the hex

shaft to the left and into the left bearing being sure flat

washer is in position. See that the pinion gear meshes with

the iarge gear.

8

.

Replace the bearing flange on the right side of the frame

and secure with the four carriage bolts and nuts. Reconnect

the traction clutch rod in the clutch fork arm and secure

with a hairpin cotter. Readjust the drive disc as described

in the paragraph on page 6.

NOT AN ADJUSTMENT

^

FORK

FLAT WASHER

{OUTSIDE OF

PINION)

TRACTION CLUTCH ROD

LUBRICATION

ENGINE

Fill the crankcase with Ariens Sno-Thro oil 5W-20 when using

the Sno-Thro.

Use Ariens Gard-N-Yard oil MS classification SAE-30 when

using lawn attachments.

Refer to engine owners manual for appropriate crankcase oil

substitutes.

Fill the fuel tank with fresh, clean, unleaded automotive type

gasoline. (Leaded "regular" grade gasoline is an acceptable

substitute.)

NOTE: For detailed instructions on engine refer to manu

facturer's booklet packed with the machine.

TRACTOR DRIVE

At start of season, grease gears, hex and axle shaft as in

dicated in the figure below. Use Ariens Moly Lithium grease.

Put two or three drops of light oil on shift lever and other

linkage points.

CAUTION:

Do

not

allow

grease

or

oil

to

come in contact with friction wheel, drive disc or belts.

y

/ A

BEARING FLANGE

FRICTION WHEEL

SNO-THRO UNIT

Check the lubrication in the blower gear case by removing

the filler plug on the side of the gear case just above the left

hand auger shaft. Lubricant should be even with the hole

with the machine sitting level.

To Drain Gear Case: Remove fill plug. Tip up on blower

housing and allow oil to drain. Tip unit back on wheels.

Fill gear case with Ariens Liquid Grease (Part No. 000070).

SHEAR BOLT I

SHAFT

FILLER PLUG

Oil rake shaft periodically or each time a shear bolt is re

placed. At the end of the season, remove shear bolts, oil

rake shaft through shear bolt holes, turn rakes on shaft

several times and replace shear bolts.

Oil the discharge chute with several drops of heavy oil.

- 7 -