Maintenance – Ariens Sno-Thro PM-32-77 User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

MAINTENANCE

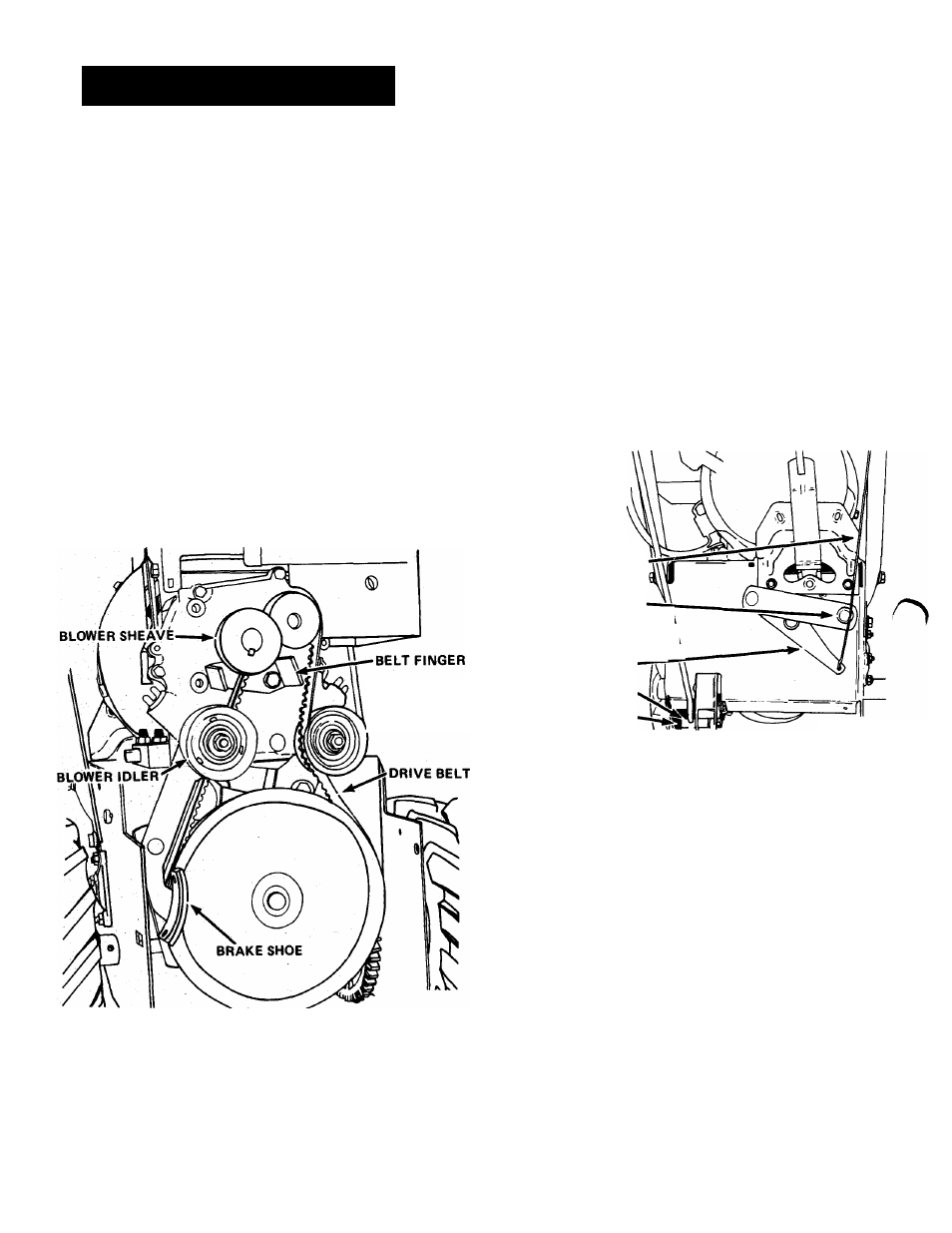

BELT REPLACEMENT

CAUTION:

SINCE REPLACING THE BELTS WILL INVOLVE TURNING

THE ENGINE OVER WITH THE STARTER, THE SPARK

PLUG WIRE MUST BE DISCONNECTED DURING THIS

PROCEDURE.

The drive belt and the attachment drive belt are both ac

cessible by tipping apart the blower housing and tractor as

follows;

1. Remove the nut and washer holding the worm clevis on

the bracket. Remove the chute crank by sliding it back in

the bracket and out of the way.

2. Remove the two flanged whiziock screws securing the belt

guard to the tractor. Remove the belt guard.

3. Remove the top cap screws and loosen the lower cap screws

on each side that secures the blower housing to the frame.

As the blower housing and tractor are tipped apart, roll

the belt off the engine sheave between the sheave and belt

finger. This can be easily done by pulling the recoil

starter rope to rotate the engine sheave. With the belt dis

connected, the blower housing may then be tipped from

the frame.

REPLACEMENT OF TRACTION DRIVE BELT

With the blower and tractor tipped apart, spring the idler

from the drive belt and remove from around the lower sheave

and engine sheave. Install the new belt on the engine sheave

and lower sheave. Then spring the idle back into position on

the outside of the drive belt.

With the belts in position and the idler in place, check the

belt alignment. The engine sheave and the tractor sheave

must align with one another. If the sheaves are not properly

aligned, loosen the setscrews on the engine sheave and align

the sheaves. Retighten the setscrews.

BLOWER CLUTCH ADJUSTMENT

The blower clutch is adjusted by connecting the spring on

the clutch rod into the proper link on the clutch handle chain.

Properly adjusted, the spring should be slightly extended with

the clutch handle down. This should occur without the

attachment activator lever touching the hub. If the activator

lever touches the hub, the blower belt idler pulley must be ad

justed in the idler arm. Loosen the cap screw on the idler

and move the idler IN TOWARD the belt. Readjust the spring

in the chain for proper action.

o

TRACTION IDLER

BLOWER CLUTCH ROD

HUB

TRACTION CLUTCH ROD .

M\

ACTIVATOR LEVER ^ ^

REPLACEMENT OF THE BLOWER DRIVE BELT

The blower drive belt remains on the sheave on the blower

housing. Place the new belt on the sheave. Hold it in position

On the sheave as the blower is tipped into position on the

tractor. Be sure the brake shoe seats on the belt as the units

are tipped together. Once assembled, roll the blower belt on to

the engine sheave and position the idler on the outside of

the belt.

ROD ADAPTOR

ALLEN SCREW

FIGURE 4

DRIVE DISC ADJUSTMENT

The only adjustment for the drive disc is made by adjusting

the length of the traction clutch rod. With the clutch handle

in the full upright position and the clutch bracket down

against the stop, tighten the alien screw in the rod adapter.

To check the adjustment, push the Sno-Thro with the clutch

handle up; it should roll freely. While pushing the Sno-Thro,

slowly lower the clutch handle. The wheels should start to

drag with the clutch handle approximately halfway down to

the handlebar grip when properly set. If necessary, adjust

the clutch rod in the rod adapter to secure this adjustment.

NOTE; The hex nut on the clutch link just above the spring

on the clutch linkage is NOT an adjustment. This nut should

be tightened just enough to hold the spring snug and prevent

the spring from rattling when traction clutch is released.

REPLACEMENT OF FRICTION WHEEL

1. Tip the machine up on the blower housing and brace

securely. Remove two cap screws at back of frame securing

the bottom cover and loosen two cap screws at front

frame sides and remove the cover.

-

6

-

2. Remove the four whiziock nuts holding the bearing flange

on the right hand side of the frame. Remove the bearing

flange and carriage bolts.