Checking performance problems what to do – SINGER W1866 User Manual

Page 34

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

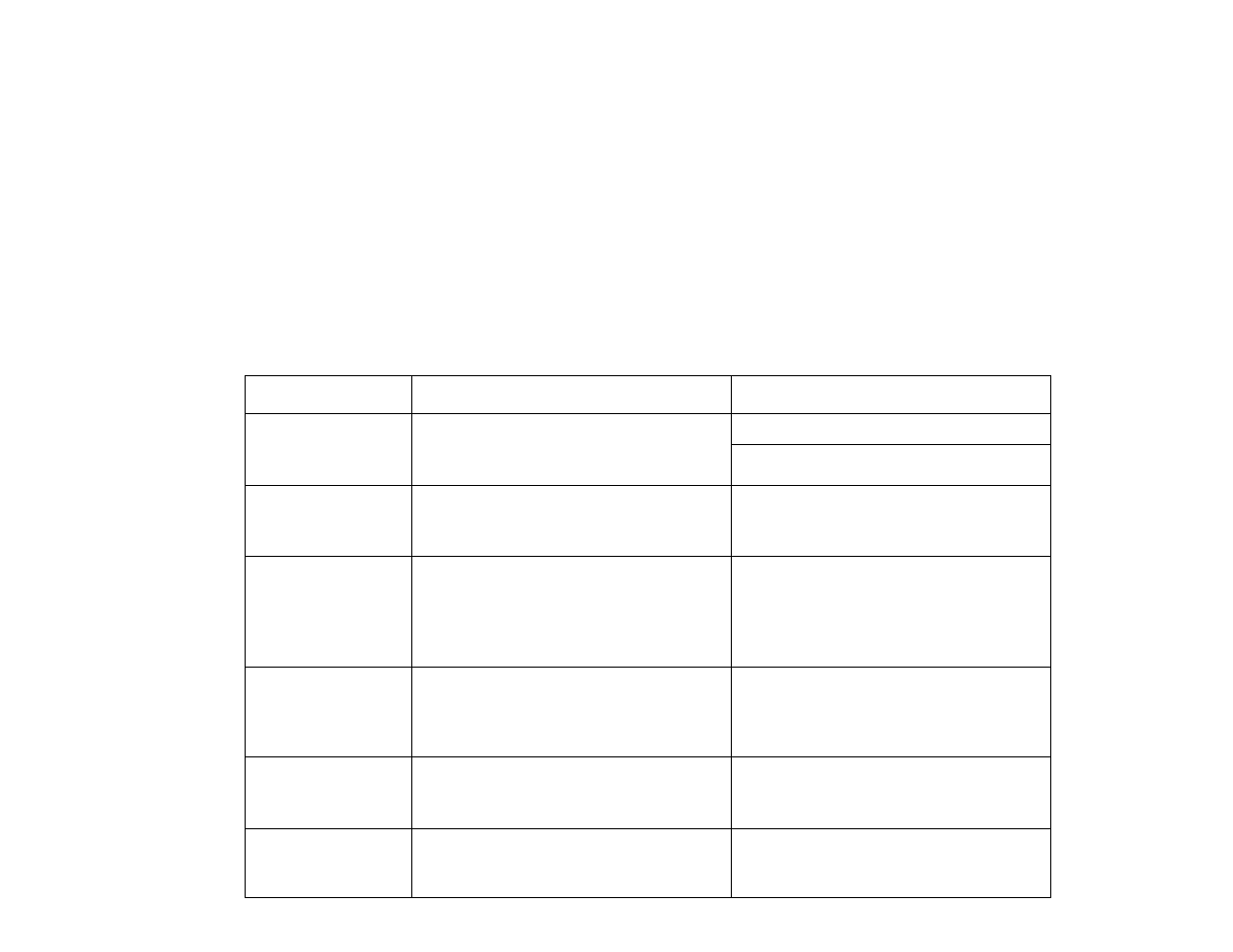

CHECKING PERFORMANCE PROBLEMS WHAT TO DO

CO

O

PROBLEM

PROBABLE CAUSE

CORRECTION

Fabric not

moving

_ Feed dog down.

- Machine not moving.

-- Stitch length dial in 0 position.

-

1 iaht pressure on presser foot.

-

Raise feed dog.

- Moving stop motion.

- Moving dial to 1-4.

-

Increase pressure on presser foot.

Breaking

Needle

-

Incorrect setting of needle.

^ Needle bent.

-

Pulling fabric.

^ Incorrect using needle, thread and fabric.

^ Reset needle.

-

Replace new needle.

- Do not pull fabric.

- Correct using needle, thread, and fabric.

Breaking Upper

Thread

- Incorrect position of zigzag width dial.

-

Improper threading.

-

Tight upper thread tension.

-

Needle bent.

- Nicks or burrs on shuttle.

- Moving to correct position.

-

Rethread machine.

-

Loosen upper thread tension.

-

Replace new needle.

-

Replace shuttle, or polish off burrs

completely.

Breadkin Bobbin

Thread

Tight bobbin thread tension.

-

Incorrect setting of needle.

-

Improper threading.

- Dust and thread in shuttle.

-

Loosen bobbin thread tension.

- Reset needle.

-

Rethread machine.

- Clean shuttle.

Machine Jamming

Knocking Noise

- No oil.

- Dust and thread in shuttle.

-

Need oil.

- Clean shuttle.

Puckering

-

Tension too tight.

- Sewing foot pressure too strong.

-

Incorrect using fabric, needle, and thread.

- Reset.

- Regulating sewing foot pressure.

- Correct using fabric, needle and thread.