Automatic cool down system (thermal relief), Maintenance, Owner’s responsibilities – Sears 580.76101 User Manual

Page 9: Maintenance -12, Pressure washer rinsing

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Pressure Washer Rinsing

A

WARNING! Be extremely careful if you use the

pressure washer from a ladder, scaffolding or

any other relatively unstable location. Pressure

in a running washer builds as you climb. When

you press the trigger, the recoil from the initial

spray could cause you to fall. The high pressure

spray could also cause you to fall if you are too

close to the cleaning surface.

For Rinsing:

• Slide the nozzle backward to high pressure, press

the trigger and wait for the detergent to clear.

NOTE: You can also stop detergent flow by removing

detergent siphoning tube from container.

• Keep the spray gun a safe distance from the area

you plan to spray.

• Apply a high pressure spray to a small area, then

check the surface for damage. If no damage is

found, it is okay to continue cleaning.

• Start at the top of the area to be rinsed, working

down with same overlapping strokes as you used

for washing and applying detergent.

Automatic Cool Down System

(Thermal Relief)

If you run the engine on your pressure washer for

3-5 minutes without pressing the trigger on the spray gun,

circulating water In the pump can reach temperatures

between 140-145T. The automatic cool down system

cools the pump by discharging the warm water onto the

ground, preventing internal pump damage.

MAINTENANCE

OWNER’S RESPONSIBILITIES

Follow the hourly or calendar intervals, whichever occurs first.

More frequent service is required when operating in adverse conditions noted below.

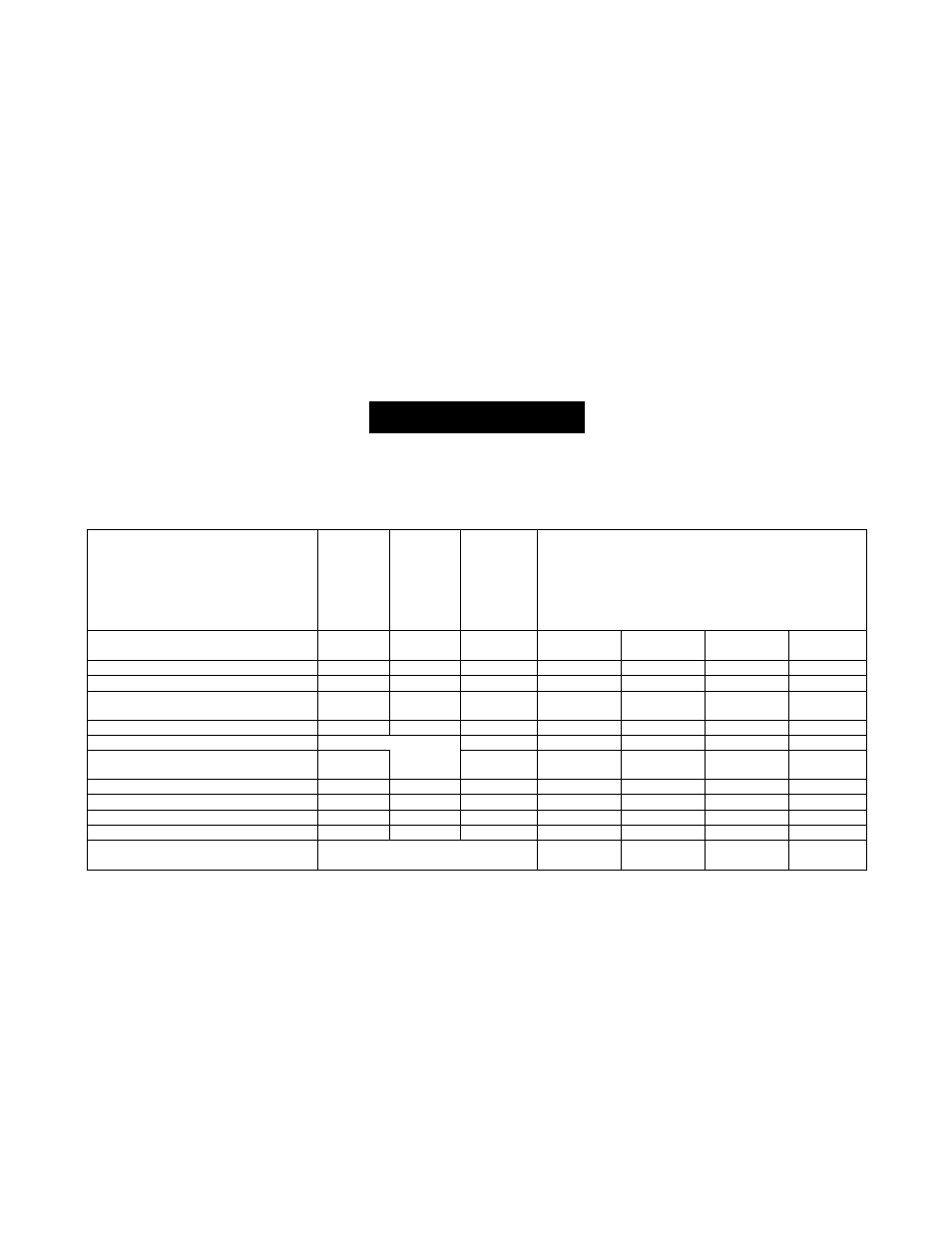

MAINTENANCE SCHEDULE

FILL IN DATES AS YOU COMPLETE

REGULAR SERVICE

MAINTENANCE TASK

HOUF

Before

Each Use

{LY OPEFi/

INTERVAL

Every 50

Hours or

Yearly

\TING

Every 100

Hours or

Yearly

SERVICE DATES

PRESSURE WASHER

Check/clean water inlet screen

X'

Check hiah oressure hose

X

Check deteraent hose

X

Check spray gun and assembly for

leaks

X

Purae Dumo of air and contaminants

X

Preoare oumo for storaae below 32°F

See "

3aqe 13.

ENGINE

Check oil level

X

Chanae enaine oil

X^

Service air cleaner

X-

Service soark oluo

X

Service soark arrester

X

Prepare for storage

If unit is to remain idle for

lonaer than 30 davs.

Clean if clogged. Replace if perforated or torn.

Change oil after the first (5) operating hours and every 50 hours or yearly thereafter.

Change sooner when operating under dirty or dusty conditions.

Replace more often under dirty or dusty conditions.