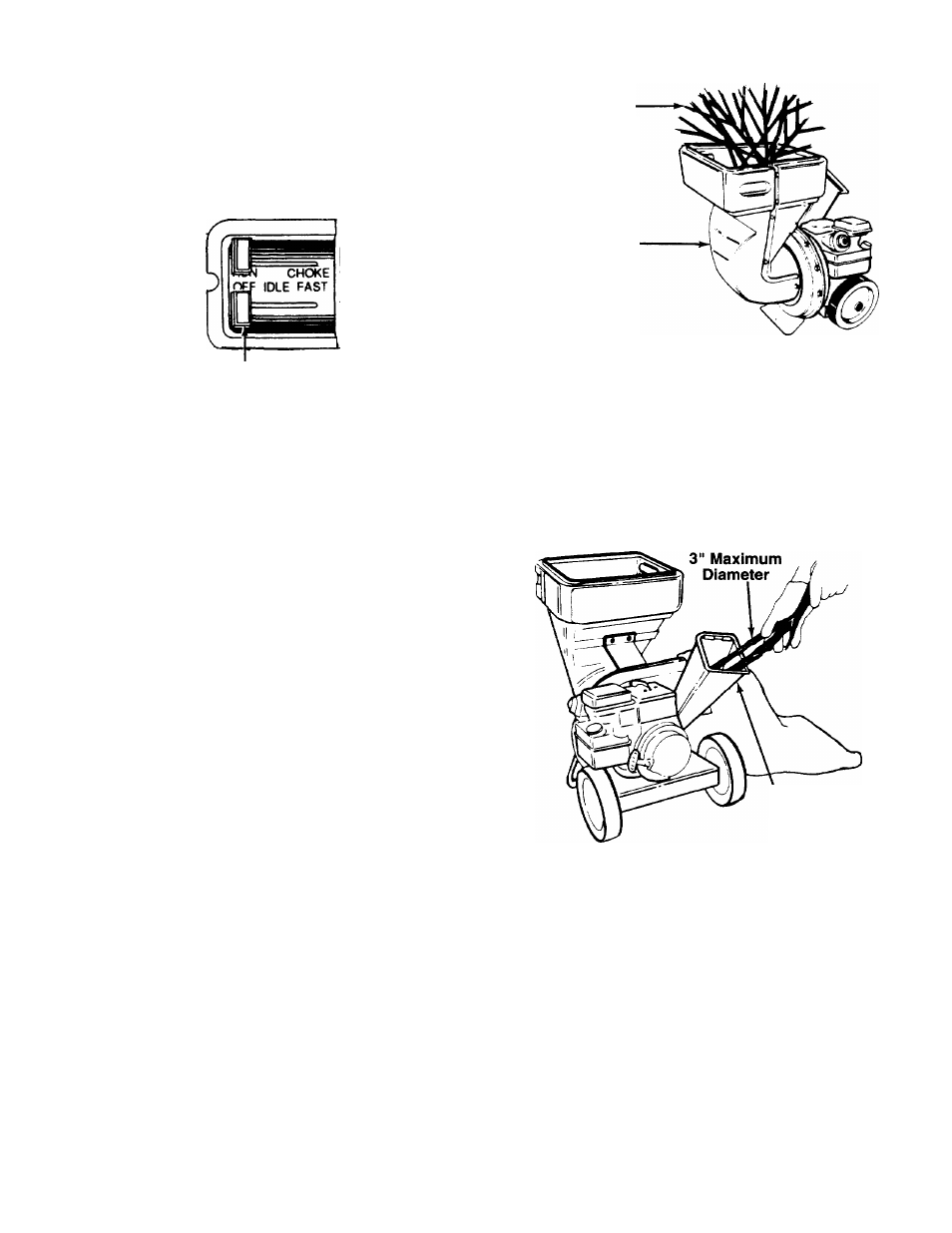

To stop engine, Figure 4, How to use your chipper-shreoder – Sears 247.799892 User Manual

Page 7: Figure 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

TO STOP ENGINE

•

Move throttle control lever to OFF position. See fig

ure 4.

•

Disconnect

spark

plug

wire

and

move

away

from

spark

plug

to

prevent

accidental

starting

while

equipment is unattended.

L

Throttle Control

FIGURE 4.

HOW TO USE YOUR CHIPPER-SHREODER

Do

not

attempt

to

shred

or

chip

any

material

other

than

vegetation

found

in

a

normal

yard

(i.e.,

branches,

leaves, twigs, etc.).

A

WARNING:

THE

CHIPPER-SHREDDER

DISCHARGES MATERIALS WITH CONSID

ERABLE VELOCITY. KEEP AWAY FROM

THE

AREA

AROUND

THE

CHUTE

DEFLECTOR.

ALWAYS

STOP

THE

ENGINE AND DISCONNECT THE SPARK

PLUG

WIRE

WHEN

REMOVING

OR

ATTACHING THE BAG, WHEN CHANGING

CONTAINERS OR WHEN REMOVING THE

SHREDDED

MATERIAL.

WEAR

SAFETY

GLASSES

AND

GLOVES

WHENEVER

USING YOUR CHIPPER-SHREDDER.

The

chipper-shredder

is

designed

for

two

different

methods of operation.

•

Leaves

and

small

branches

up

to

1/2"

diameter

(recommended)

or

1"

diameter

(maximum)

can

be

fed

into

the

hopper

assembly.

See

figure

5.

If

it

becomes

necessary

to

push

material

into

the

chip

per-shredder,

use

a

small

diameter

stick—NOT

YOUR

HANDS.

The

stick

should

be

small

enough

that

it

will

be

ground

up

if

gets

into

the

impeller

assembly.

A

WARNING:

DO

NOT

PUT

MATERIAL

LARGER THAN 1/2" IN DIAMETER (REC

OMMENDED)

or

1"

DIAMETER

(MAXI

MUM) INTO THE HOPPER ASSEMBLY.

MATERIAL UP TO A MAXIMUM OF 3" IN

DIAMETER

MATERIAL

MAY

BE

FED

INTO THE CHIPPER CHUTE. DO NOT

ATTEMPT

TO

SHRED

OR

CHIP

ANY

MATERIAL LARGER THAN 3" IN DIAME

TER. PERSONAL INJURY OR DAMAGE

TO THE MACHINE COULD RESULT.

No Larger Than

1/2" Diameter

(Recommended)

Or 1" Diameter

(Maximum)

Hopper

Assembiy

FIGURE 5.

•

Bulky

material,

such

as

stalks

or

heavy

branches,

up to 3" in diameter,

should be fed into the chip

per chute. See figure 6.

A

WARNING: MAKE CERTAIN THE CHIP

PER CHUTE DOOR IS CLOSED WHEN

NOT IN USE.

Chipper

Chute

FIGURE 6.

IMPORTANT:

There

is

a

flail

screen

located

inside

the

housing

in

the

discharge

area.

If

the

flail

screen

becomes

clogged,

remove

and

clean

as

instructed

in

the

Service

and

Adjustments

section.

For

best

per

formance,

it

is

important

to

keep

the

shredding

blade

and

the

chipper

blades

sharp.

If

the

composition

of

the

material

being

discharged

changes

(becomes

stringy, etc.) or if the rate at which the material is dis

charged

slows

down

considerably,

it

is

likely

that

the

shredding

blade

and/or

chipper

blades

are

dull

and

need

to

be

sharpened

or

replaced.

Refer

to

Service

and Adjustments section.