Operating instructions (confd) – Sears 257.79605 User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

OPERATING INSTRUCTIONS (confd)

TO REPAIR BROKEN CUTTING LINE

1.

Stop the motor an unplug power cord.

2.

Visible cutting fine can be retrieved vwtfi needle nosed pliers,

3.

Hub should be depressed and released while keeping tension

on the cutting line. One inch of cutting line shouW feed each

time the hub is depressed.

4.

If cutting line cannot be retrieved, foitow instructions under

SPOOL REPLACEMENT.

SPOOL REPLACEMENT

1.

2

.

3.

4.

6

.

7.

8

.

9.

Stop motor and unplug power cord.

Restrain rearplate^push iniockbuttonflocated on hub),and twist

huboourtter-clockwiseuntil locking tabs disengage Remove hub.

Remove spool from assembly and remove spring from spool.

Rewindspooi i n accortance with the instructions inciuded herein

{fig. 8) or replace spoof as appropriate.

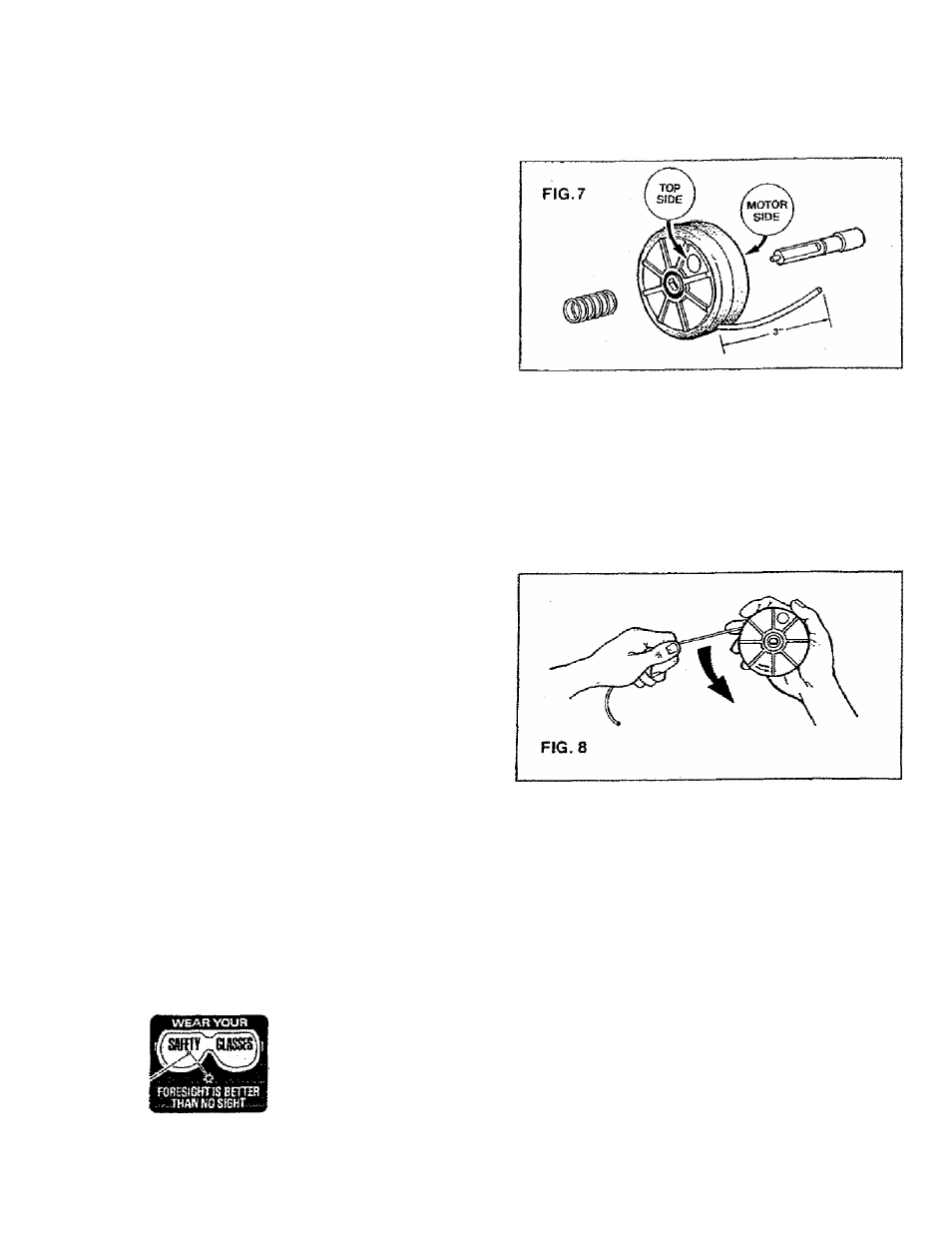

Before reinstaiTing spool be sure approximatety 3 Inches of fine

exits spool

between

the two foam pads as shown In fig. 7.

Install spring on ‘TOP SIDE” of spool. See fig. 7.

insert fine thru eyelet in hub assembly and seat spring end onto

center post inside hub asserabiy.

NOTE Make sure line does notgettrapped under spool, between

the spool and hub assembly.

Slide spool and hub assembly onto motor shaft. Manipulate parts

slightly to obtain proper alignment Align locking tabs on hub

assembly with slots in rear plate and insert tabs infoslots until

parts bottom. Rotate hub assembly clockwise white restraining

the rear plate until all four locking tabs are properly engaged.

Remove debris from u nderside of your WEEDWACKER.

IF UNE DOES NOT FEED

1.

Follow instructions 1-3 under "Spoor Replacement.”

2.

Check to make sure line is wound in direction indicated

on spool, .

3.

Separate strands of tangled line or install new line if

necessary.

4.

Inspect foam pad for tears of damage, replace if necessary.

5.

Check spring for damage and proper iftstallation.

6- R)llow instructions 5 thru 11 under “Spool Replacement”

REWINDING SPOOL

When rewinding be sure to wind the line in the direction of arrow

indicated on spool (Fig. s) Plastic is a memory material and the line

should be recoiled form the original сой to the spool in a way so the

built-in memory tends to keep the coils tight to the spool. If you гесоП

in the oppbsfe direction thé coils would be loose atKÏ terrd to cóme

unwound. To secure line to spool, place tape over approx. 1 Va’ of

line, then secure tape to spool. Une must be wound side by side

avoiding crossoveror crisscrossing to insure proper line advancing.

Do not wind more than a total of 40 te« of line onto spool.

RECOMMBJDED REPLACEMENT PARTS

AND ACCESSORIES

Your SEARS WEEDWACidER uses SrcCIAtXY TREATED .065

DIAMETER MONOFILAMENT NYLON cutting line which is available

at SEARS STORES AND CATALOG STORES. You may purchase

a fully wound spool {Part No. B5744) or you may purchase a package

of two 50 foot coils (Part No. 85772) or a large bulk spool of line and

rewind your present spool.

CAUTION: The use of heavier fine, different types of line and ac

cessories or attachments other than recommended may be hazar

dous or cause unit feilure.

THEOPERATiON OF ANY TRIMMER CAN RESULT IN FOREIGN OBJECTS BEING THROWN

INTO TH E EYES, WHICH CAN RESULT IN SEVERE EYE DAMAGE. ALWAYS WEAR SAFETY

GLASSES OR EYE SHIELDS BEFORE COMMENCING POWER TOOL OPERATION. WE

RECOMMEND WIDE VISION SAFETY MASK FOR OVER SPECTACLES OB STANDARD

SAFETY GLASSES AVAILABLE AT SEARS RETAIL OR CATALOG STORES.

5