Maintenance, A danger a, Caution – Sears 536.9183 User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

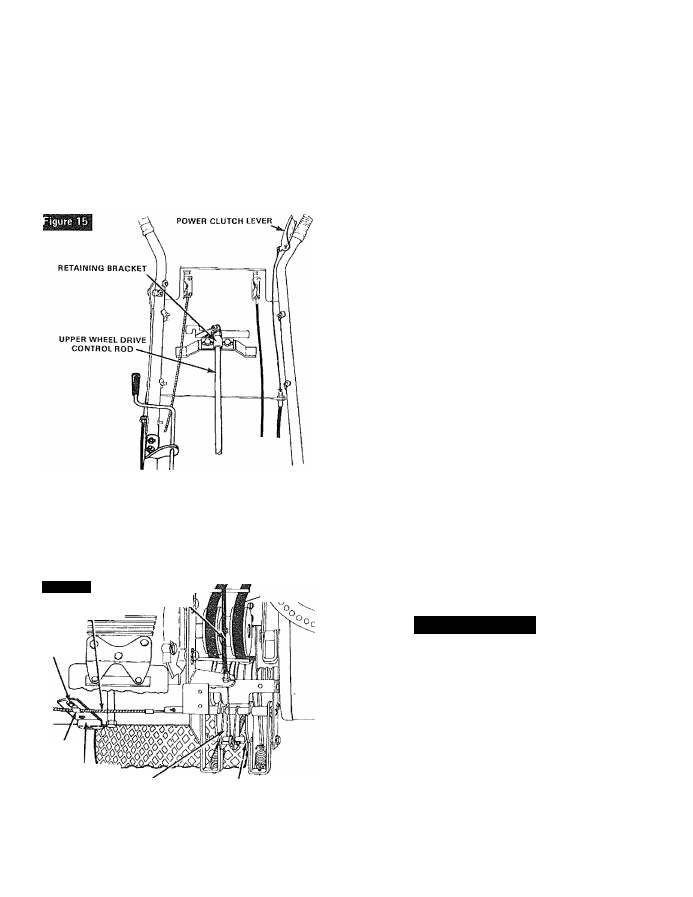

B. Leave wheel drive control lever in position where

neutral was obtained and release power cutch

lever. Shut off engine.

C, Loosen screws in retaining bracket (figure 15) at top

end of wheel drive control rod(under control panel),

D. Slide retaining bracket and rod left or right until

wheel drive control lever Is in proper neutral

position. Tighten screws in retaining bracket,

E, Start engine and check adjustment by moving lever

to each position, NOTE: Be sure to check to see that

NEUTRAL is property reached from both directions

{from reverse and from forward gear).

IMPELLER/AUGER CONTROL CABLE

ADJUSTMENT

If impeller/auger control should need adjustment because

impeller/auger will not engage or will not disengage, adjust

as follows:

1. Remove belt cover (figure 11).

Figure 16

IMPELLER/AUGER

CONTROL CABLE

SCREW

POWER CLUTCH CABLE

Ys

CLAMP

CABLE BRACKET

SELECTOR ARM

Va

INCH CLEARANCE

2.

Move impeller/auger control lever from OFF to

ENGAGE and check action of selector arm {figure 16). When

impeller/auger control lever is in ENGAGE position, pin

through selector arm should fully engage wheel drive arm

and impeller/auger drive arm. When lever is in OFF position,

pin through selector arm should engage wheel drive arm

only and clear impeller/auger drive arm by at least Vs inch.

To adjust to these positions;

A. Loosen screw that clamps impeller/auger control

cable to cable bracket (figure 16).

B. Move cable forward or backward in clamp to obtain

proper position mentioned above.

C. Reclamp cable by tightening loosened screw.

A DANGER A

Never attempt to manually stop auger from turning.

CARBURETOR ADJUSTMENT

HIGH SPEED and IDLE ADJUST NEEDLES are pre-set at the

factory and re-adjustment should notbe necessary. NOTE: If

you think the carburetor needs adjusting, contact your

nearest

SEARS

Service

Center

who

has

the

proper

equipment

and

experience

to

make

any

necessary

adjustments.

A

CAUTION

A

Never tamper with engine governor which isfactory

set for proper engine speed. Over-speeding engine

above factory high speed setting can be dangerous.

If you think the engine governed high speed needs

adjusting,

contact

your

nearest

SEARS

Service

Center

who

has

the

proper

equipment

and

experience to make any necessary adjustments.

Changing of engine governed speed will void engine

warranty.

SPARK PLUG ADJUSTMENT

Check the spark plug periodically and reset spark plug gap to

0.030 inch using a wire feeler gauge.

The condition of the spark plug may be determined by color.

A carbonized plug is black and burnt plugs are greyish in

color, whereas a normal functioning spark plug is brown. If a

new spark plug is required, refer to the Engine Repair Parts

section for proper replacement spark plug.

Before

installing

spark

plug,

coat

threads

lightly

with

graphite grease to insure easy removal.

MAINTENANCE

DRIVE BELT REPLACEMENT

The drive belts on this unit are of special construction and

should be replaced with original equipment belts available

from your nearest SEARS Store or Service Center,

To Replace Unit Drive Belt (belt nearest engine):

1. Remove belt cover (figure 11).

2.

Loosen screw holding left belt guide (figure 12) and

swing guide away from pulley. Retighten screw.

3. Loosen screw holding right belt guide (figure 12) and

swing guide away from pulley. Retighten screw.

4. Roll belt off engine pulley. NOTE: It will be necessary to

roll impeller/auger drive belt off engine pulley to allow unit

drive belt to be removed from engine pulley.

5.

Remove belt by threading up between large drive

pulleys.

6. Install new belt in reverse order.

—10-