Waste line connection, Changing restrictor orifice, Restrictor orifice selection – Sears EF12F1900A2 User Manual

Page 5: Refrigerant line connections

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Electric Furnace

Installation Instructions

3. Routetotheoutsideortoafloordrain, laundry tray or waste

line (sewer). Check local codes before connecting to a

sewer line.

4. Insulate drain lines where sweating could cause water

damage,

5. If a gravity drain cannot be used, install a condensate

pump. Install the pump as close to the indoor section as

possible.

Special Note For Downflow Installations

For downflow installations, a secondary overflow drain

connection must be installed to prevent water from dripping onto

live electrical components. Use the secondary fitting on the

evaporator coil,

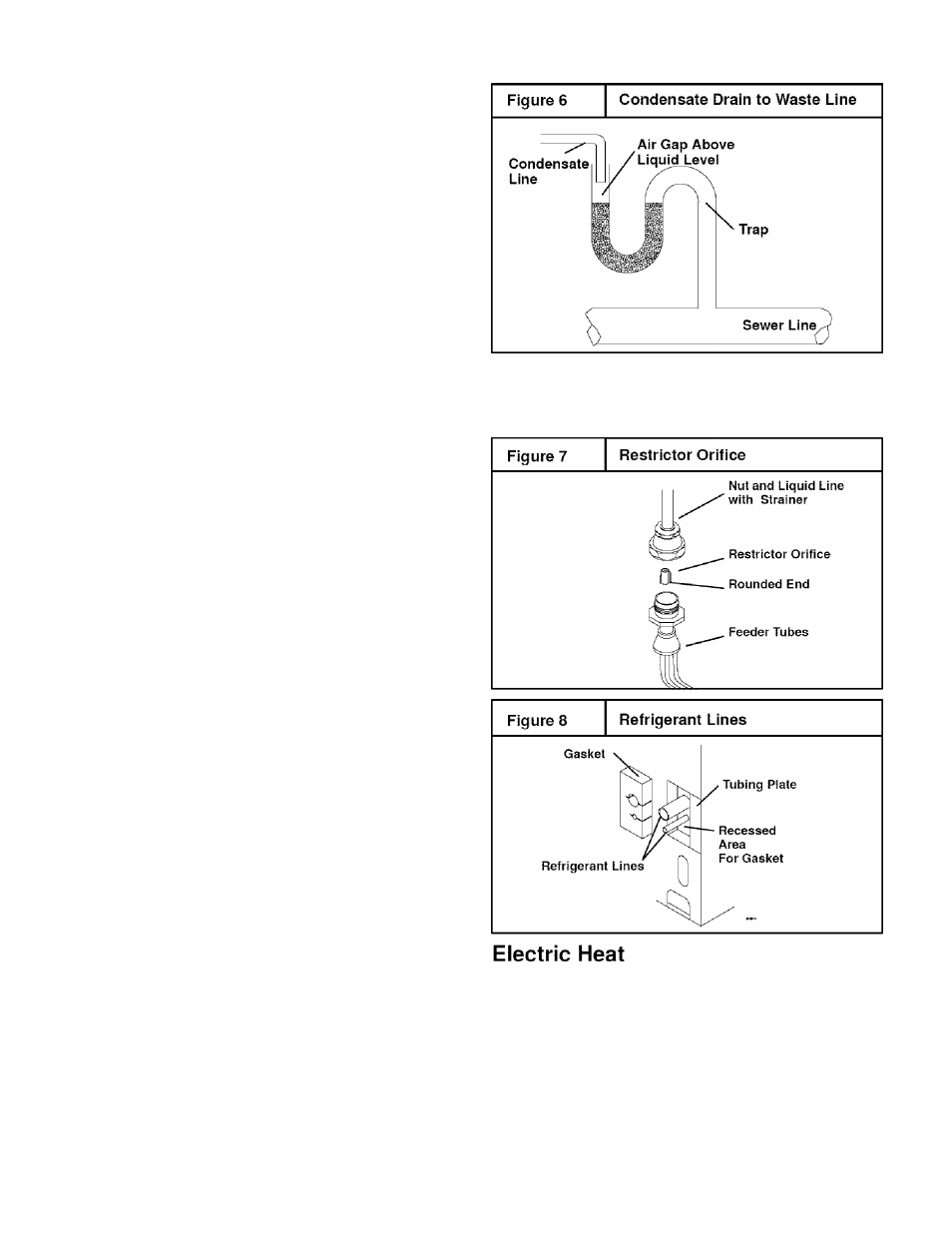

Waste Line Connection

If the condensate line is to be connected to a waste line, an open

trap must be installed ahead of the waste line to prevent escape of

sewer gases. NEVER CONNECT THE DRAIN LINE DIRECTLY

TO A WASTE LINE. ALWAYS INCLUDE AN AIR GAP AND

TRAP, (Figure 6). Be sure to keep the trap filled with water during

the winter or off season.

Restrictor Orifice Selection

A restrictor orifice is located in a fitting at the distributor. The facto

ry installed restrictor orifice is identified on the unit rating plate.

The restrictor orifice may require changing to obtain best perfor

mance. Refer to the restrictor charts furnished with the outdoor

unit.

Changing Restrictor Orifice

1. Remove the liquid line fitting and replace restrictor orifice.

(STANDARD RIGHT HAND THREAD)

2. Make sure the restrictor is installed with the rounded end to

ward the feeder tubes. See Figure 7.

Refrigerant Line Connections

Size refrigerant lines according to information provided with out

door condensing unit, Route the refrigerant lines to the coil in a

manner that will not obstruct service access to the unit or removal

of the filter.

1.

Remove rubber plugs from refrigerant connections using a

pulling and twisting motion. Hold refrigerant lines to avoid

bending or distorting.

2.

Remove the coil door before brazing refrigerant connec

tions to prevent damage to paint finish.

3.

Fit refrigerant lines into coil connections and remove the

tubing plate and slide plate over the refrigerant lines to as

sure sufficient room for brazing.

4.

Reinstall tubing plate and door and install the gasket, pro

vided with the unit, overthe suction and liquid lines into the

tubing plate recess to ensure an air seal around the coil.

See Figure 8.

Refer to Electric Heat Installation Manual to install heaters.

442

01

2204

01