Electrode setting, Turbulator setting, Oil line connections – Sears Riello F10 User Manual

Page 10: Electrode setting turbulator setting

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

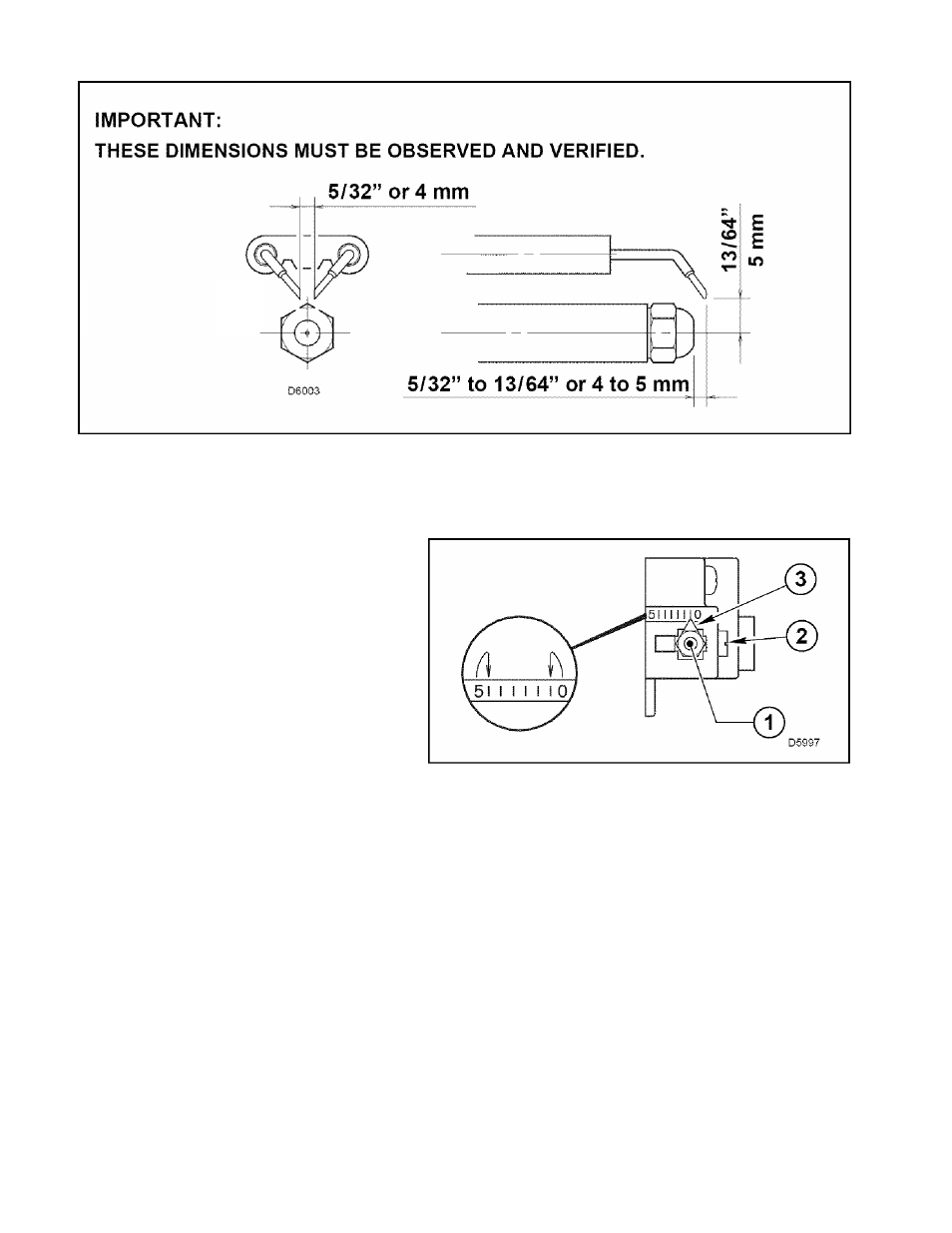

ELECTRODE SETTING

TURBULATOR SETTING

A) Loosen NUT (1), then turn SCREW

(2) until the INDEX MARKER (3) is

aligned with the correct index number

as per the Burner Set-up chart, on

page 12.

B) Retighten the RETAINING NUT (1).

NOTE: Zero and five are scale indica

tors only. From left to right, the first line

is 5 and the last line 0.

OIL LINE CONNECTIONS

This burner is shipped with the oil pump set to operate on a

single line system.

To operate on a

two line system the by-pass plug must be installed.

Warning: Do not operate a single line system with the by-pass plug installed.

Operating a

single line system with the by-pass plug installed will result in damage

to the pump shaft seal.

Note: Pump pressure must be set at time of burner start-up. A pressure gauge is

attached

to

the

PRESSURE

PORT

(8)

for

pressure

readings.

Two

PIPE

CONNECTORS (5) are supplied with the burner for connection to either a single or a

two-pipe system. Also supplied are two

ADAPTORS (3), two female 1/4” NPT, to adapt

oil lines to burner pipe connectors. All pump port threads are

British Parallel Thread

design. Direct connection of NPT threads to the pump

will damage the pump body.

F 1 0 - 8