Awarning, Acaution, Piping acaution – Sears 919.18416 User Manual

Page 7: Lubrication and oil acaution, Wiring instructions awarning

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

INSTALLATION AND BREAK-IN PROCEDURES (Cont.)

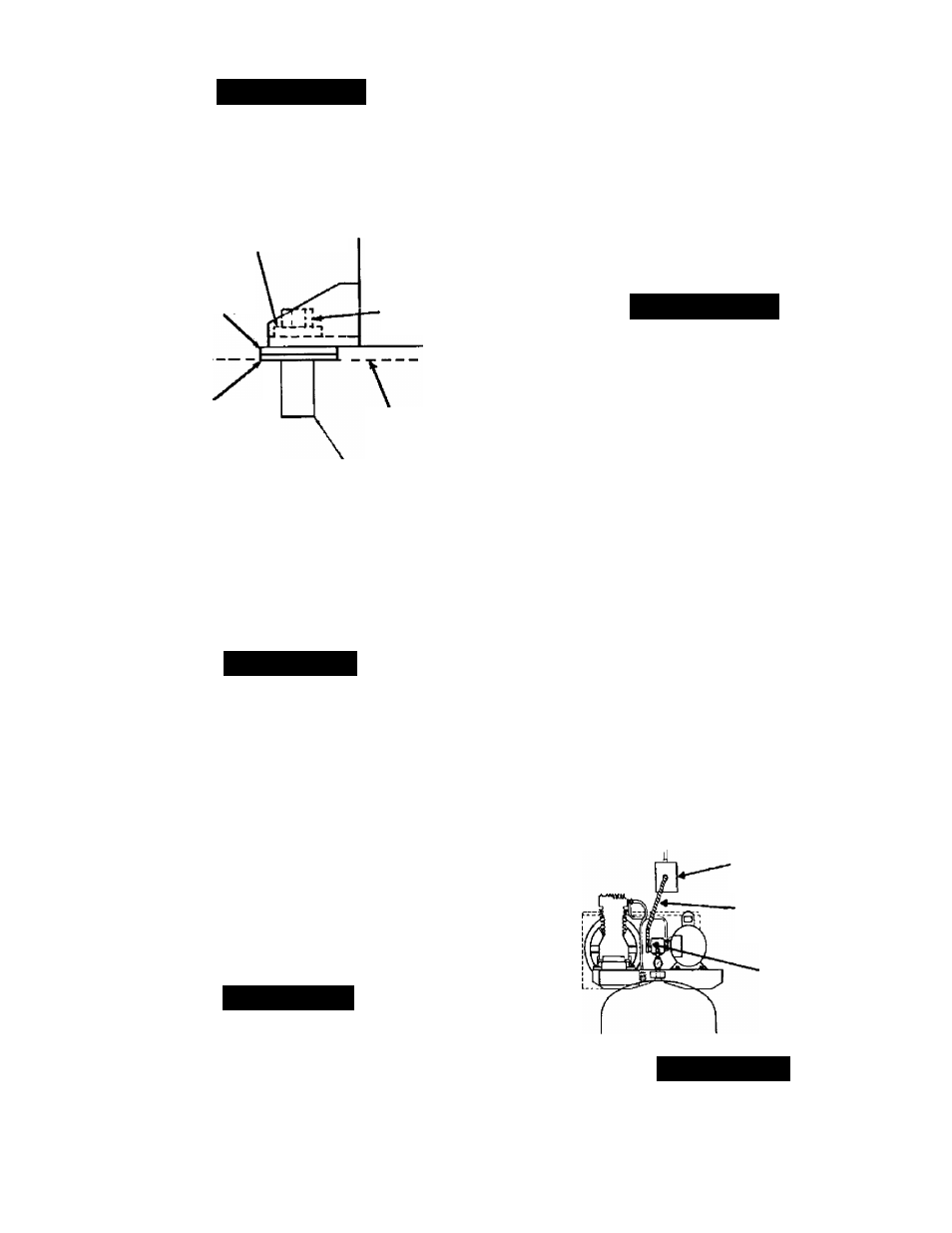

AWARNING

EXCESSIVE VIBRATION MAY WEAKEN THE

AIR TANK AND CAUSE AN EXPLOSION. THE

OUTFIT MUST BE MOUNTED AS DESCRIBED

AND ILLUSTRATED BELOW.

SS-IS25-CD 3/e FLAT WASHER

(SUPPLIED ON LEGS AS PART

OF PACKAGING)

CAC-1003

ISOLATOR

WASHER

(SUPPLIED

IN PARTS KIT)

SSF-501

3/8-LAG pCREW

torqu

'

e

to

S TO T FT-LB

SHIM UNDER ISOLATOR

WASHER IF NECESSARY

(NOT SUPPLIED)

FLOOR LINE

LAG SCREW

ANCHOR FOR CONCRETE

(NOT SUPPUEDt

1

.

2

.

The air compressor must be bolted to the floor.

Bolting holes are provided in the base feet.

Mount the air compressor on a solid level founda

tion with no strain to the air tank feet. Solid shims

may be used if necessary.

Piping

ACAUTION

Plastic or PVC pipe is not designed for use with

compressed air. Regardless of its indicated pres

sure rating, plastic pipe can burst from air pres

sure. Use only metal pipe for air distribution lines.

If a pipe line is necessary, use pipe that is the same size

as the air tank valve. Piping that is too small will restrict

the flow of air. If piping is over 100 feet tong, use the next

larger size. Bury underground lines below the frost line

and avoid pockets where condensation can gather and

freeze.

Apply

pressure

before

underground

lines

are

covered to make sure all pipe joints are free of leaks.

Lubrication and Oil

ACAUTION

Compressors are shipped without oil. Do not at

tempt to operate №is air compressor without first

adding oil to the crankcase.

Place unit on a level surface. Remove oil fill plug and

slowly add a special compressor oil such as Sears 9-

16426or SAE-20-20W SF motor oil until it is even with the

top of the oil fill

hole. {It must not be allowed to be lower than 3/8" - 6

threads down - f rom the top.) When fi II ing the crankcase,

the oil flows very slowly. If the oil is added too quickly,

it will overflow and appear to be full. (Crankcase oil

capacity is 16 fluid ounces.) Under winter-type condi

tions use SAE10W oil. (Multi-viscosity oil -10W30 - will

leave carbon deposits on critical components reducing

performance and compressor life.) Replace oil fill plug.

Wiring Instructions

AWARNING

IMPROPER GROUNDING CAN RESULTIN ELEC

TRICAL SHOCK. WIRING OF THE PRESSURE

SWITCH, ELECTRIC MOTOR AND MANUAL ON/

OFF SWITCH SHOULD BE DONE BY A LICENSED

ELECTRICIAN

IN

ACCORDANCE

WITH

NA

TIONAL AND LOCAL CODES AND ORDINANCES.

To prevent added current draw and motor overheating

we recommend the use of 12 gauge (AWG) wire, not

exceeding a 70 foot length. The wire must be rated at a

minimum temperature of 75® C.

When connect! ng wires, make surethat:(1)the electrical

box is large enough; (2) service is of adequate amperage

rating: (3) the supply line has the same electrical charac

teristics (voltage, cycles and phase) as the motor; (4) the

line wire is the proper size and (5) no other equipment is

operated from the same line. Various national and local

codes and standards have been set up covering elec

trical apparatus and wiring. These should be consulted

and observed. Our recommended wire sizes may be

smaller than the minimum set up by local ordinances. If

so, the larger size wire should be used to prevent

excessive line voltage drop. For wiring instructions, see

the diagram inside the pressure switch cover.

WALL MOUNTED

JUNCTION BOX

OR DISCONNECT

LIOUIDTtTE FLEXIBLE

METAL CONDUIT WITH

GROUND LEAD

CONDUIT ELBOW

ACAUTION

Electrical wiring must be located away from hot

surfaces such as the compressor head, compres

sor cylinder or compressor outlet tube.

7-Eng