Fig. 6, B. soldered copper fittings, fig. 2 – Sears 625.3438 User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

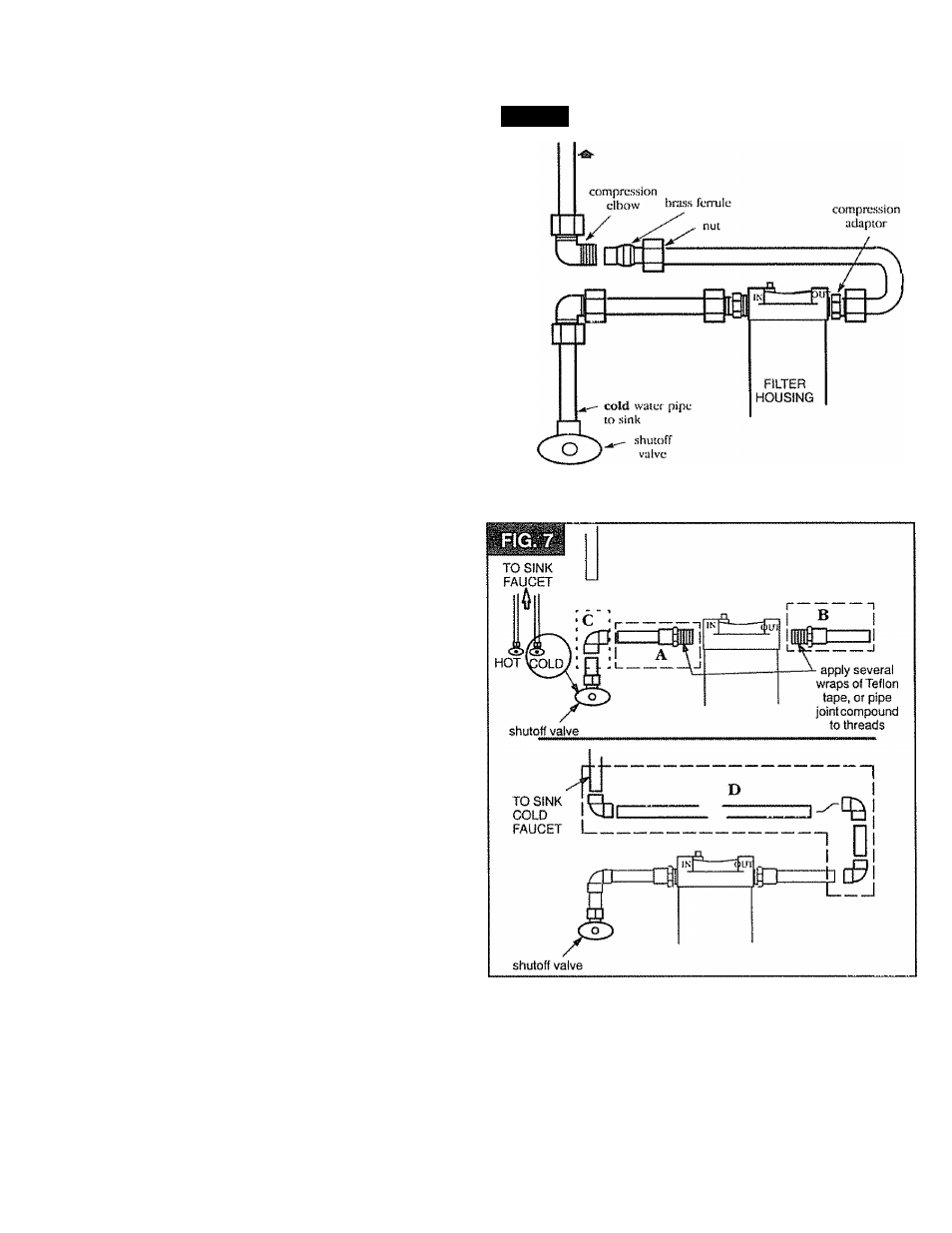

INSTALLATION STEPS

6

.

Using fentiles and compression nuts, cut and fasten

a length of tubing (allow some slack) from the cold

water pipe, to the filter head inlet compression adap

tor, FIG5-

7. Cutting to the length needed to allow some slack,

fasten tubing to the filter outlet side compression

adaptor, returning to the sink cold water pipe, as typi

cally shown in FIG, 6,

8.

Check to be sure all fittings are tightened

9. Before turning on the water supply, r emove the

sump from the filter head and install die filter cartridge

(see page 7).

FIG. 6

TO SINK

COLD FAUCET

B.

SOLDERED COPPER FITTINGS, FIG. 2

MATERIALS AND TOOLS NEEDED: You will need 2

sweat adaptors, 3/8" NPT x sweat (sweat end to fit

your sink cold water pipe), 4 sweat 90°elbows,

copper pipe, lead-free solder and flux, soldering

torch, Teflon tape, sandpaper or emery-cloth, open

end (to fit sweat adaptor) or adjustable jaw wrench,

CAUTION: Heat created when soldering can dam

age the water filter housing. Be sure to use the fol

lowing procedures to protect the water filter;

1. CAUnON: Turn off the water supply to the sink

cold pipe. Open the sink cold faucet to relieve pres

sure in the pipe.

Note: If the sink faucet is a single lever, mixing type,

also close the shutoff valve on the hot water side.

2. Use a tubing cutter to remove a section of the sink

cold water pipe (catch trapped water with a rag or

towel). Use sandpaper or emery-cloth to thoroughly

clean, and remove all burrs and rough edges, from

both pipe ends

Note: When soldering, use lead-free solder and Bux

only. Be sure pipe and fittings are properly cleaned.

Observe caution note above,

3. Refer to FIG, 2, page 5, and to the following draw

ings. Make typical soldered assemblies A and B as

shown in FIG, 7. After they have cooled, apply Teflon

tape or pipe joint compound to the pipe threads.

Then, tur n tliem into the filter head and tighten,

4. Solder the filter housing, with assemblies A and B

installed, to the cold water shutoff valve C. Wrap a wet

rag around assembly A to reduce heat transfer through

the pipe, and into the head

5- Protect the filter housing from soldering heat, as

you did above, and complete the connections (D) to

the faucet cold water pipe,

6. Before turuing on the water supply, remove the

sump from the filter head and install die filter cartridge

(see page /)