Homelite 24683 User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

I M— 16 0 6 0— 1 4

FIGURE 8

P

j

,'

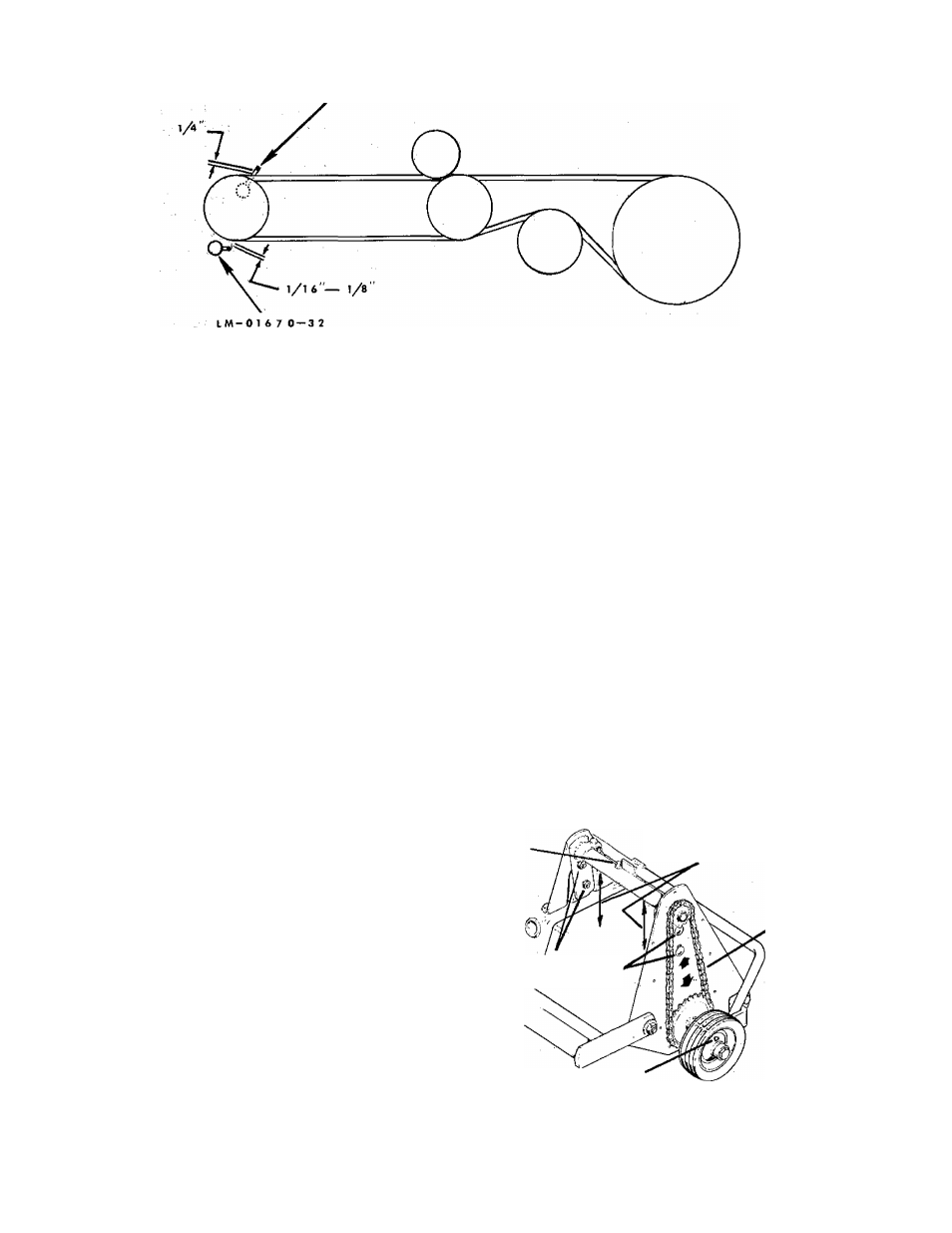

1. The belt stop located above the drive pulley is mounted

on the top mounting screw of the bevel gear case with

a special cap screw which replaces the original. This

belt stop should beadjusted to 1/4” clearance as shown

in Figure 8.

2. The belt stop located below the drive pulley is mounted

with a cap screw, flat washer, lock washer and hex nut

to the side mounting plate of the bevel gear case.

3. While holding the cap screw with a wrench so it will

not turn, loosen the nut located on the other side of the

mounting plate {see Figure 12) enough so the belt stop

can be moved. Adjust the belt stop so there is l/l6”

to 1/8” clearance between it and the revitalizer drive

belt.

4.

To prevent the belt stops from moving, use a wrench

to hold the cap screw from turning while tightening the

nut inside the frame securely.

(See figure 7) The belt guard mounted over the revitalizer

drive belt should be adjusted so there is at least 1/8” clear

ance between the guard and the belt when the revitalizer

clutch is engaged to assure the backside of the belt does not

rub against the guard. If it is necessary to adjust the guard,

loosen the two wingnuts and reposition the guard correctly.

Drive Chain Adjustment

If inspection reveals that there is slack in the drive chain or it

must be replaced, use the following procedure to tighten the

chain:

1. (See figure 9) With the chain cover removed so the chain

is visible, loosen, but do not remove the two bolts holding

each end of the bearing housing.

2. Pull upward on the bearing housing until, all slack is re

moved from the chain. Before tightening the bolts at each

end of the bearing housing, insure that the bearing housing is

parallel to the revitalizer housing. This may be easily and ac

curately done by measuring the distance from the bearing,

housing to the revitalizer housing at each end of the bearing

housing. When the two distances are equal, the bearing hous

ing is parallel to the revitalizer housing. (See figure 9).

After insuring all slack has been removed from the chain and

the bearing housing is parallel to the revitalizer housing,

tighten the two adjustment bolts at each end of the bearing

housing securely.

Put a liberal coating of automotive grease on the chain and

replace the chain cover.

GREASE

FITTING

BEARING HOUSING MUST

BE PARALLEL WITH

REVITALIZER HOUSING

LOOSEN HARDWARE

TO ADJUST CHAIN

CHAIN IS

CORRECTLY

ADJUSTED

WHEN ALL

SLACK HAS

BEEN

REMOVED

GREASE FITTING

FIGURE 9

C