A warning, Step 5 — start-up, Refrigerant charging (refer to tables 4 and 5) – Carrier 38EH User Manual

Page 4: A caution, Warning, Caution

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

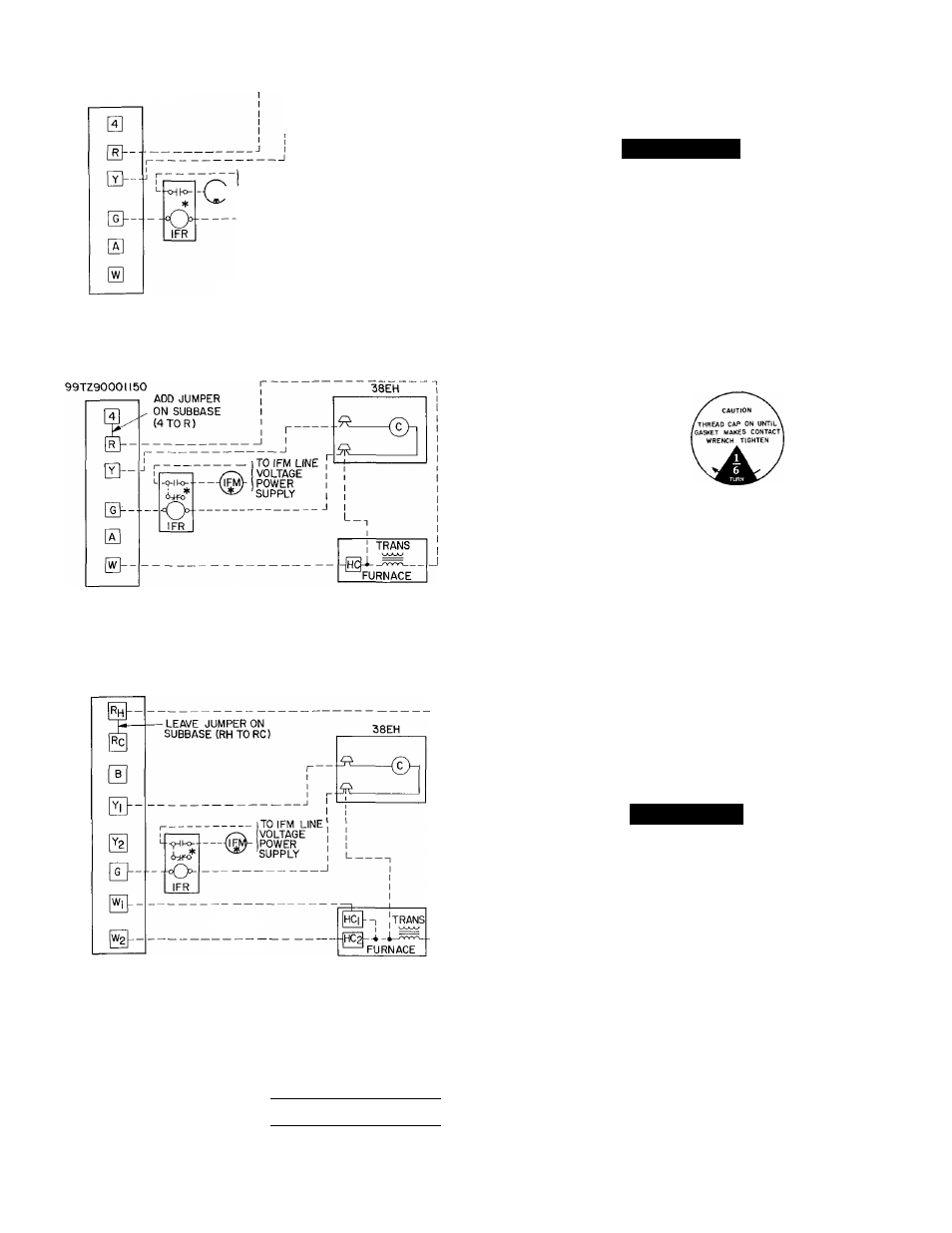

THERMOSTAT SUBBASE

99TZ90008I25 OR

99TZ9000II50

38EH

___ ^

TO IFM LINE

VOLTAGE

IFM)-|POWER

SUPPLY

TRANS

ARRANGEMENT A-(COOLING ONLY)

THERMOSTAT SUBBASE

ARRANGEMENT B-ONE TRANSFORMER

(COOLING AND ONE-STAGE HEATING)

THERMOSTAT SUBBASE

99TZ90036I20

ARRANGEMENT C-ONE TRANSFORMER

(COOLING AND TWO-STAGE HEATING)

*IFR and IFM are located in furnace on heating-cooling applica

tions If accessory IFR is required for cooling-only applications,

locate (IFR) in fan coil

c

— Contactor (12-va)

^ Field Splice

HC

— Heating Control

IFM

— Indoor Fan Motor

_ Field Wiring

IFR

— Indoor Fan Relay

Trans — Transformer

Factory Wiring

NOTE' Refer to unit wiring label for wire colors C to G and Cto Y

connections.

Fig. 5 — Control Circuit Connections

90 seconds, which provides additional cooling after

compressor has cycled off. Refer to separate installation

instructions packaged with fan time delay (shipped with

unit).

A

WARNING

To avoid personal injury, be sure indoor blower has

stopped before attempting service or maintenance.

Step 5 — Start-Up

1

.

2

.

3.

When equipped with a crankcase heater, energize

heater a minimum of 24 hours before starting unit. To

energize heater only, set thermostat at OFF position

and close electrical disconnect to outdoor unit.

Backseat (open) liquid and suction line service valves.

Unit is shipped with valve stem(s) frontseated, and

caps installed. Replace stem caps after system is opened

to refrigerant flow (backseated). Replace caps finger

tight and tighten additional 1/6 turn with wrench

See sticker on valve cap.

4. Set thermostat selector switch at OFF.

5. Set room thermostat at desired temperature. Be sure

set point is below indoor ambient temperature

6. Close electrical disconnects to energize system

7. Set room thermostat at COOL and fan switch at FAN

or AUTO, as desired. Operate unit for 15 minutes.

Check system refrigerant charge. See Refrigerant

Charging, below.

Motors and controls are designed to operate satis

factorily in the voltage range shown in Table 3. If neces

sary to use manifold gages for servicing, refer to Carrier

Standard Service Techniques Manual, Chapter 1, Refrig

erants, page 1-5, Fig. 8, for bypass method of returning

charge to system. Removal of liquid line charging hose

without following these precautions could result in some

loss of charge.

Refrigerant Charging (Refer to Tables 4 and 5)

A

CAUTION

To prevent personal injury, wear safety glasses and

gloves when handling refrigerant. Do not overcharge

system. This can cause compressor flooding.

1. Operate unit a minimum of 10 minutes before check

ing charge.

2. Measure suction pressure by attaching a gage to

suction valve service port.

3.

Measure suction line temperature by attaching a

service thermometer to unit suction line near suc

tion

valve.

Insulate

thermometer

for

accurate

readings.

4. Measure outdoor coil inlet air dry-bulb temperature

with a second thermometer.

5. Measure indoor coil inlet air wet-bulb temperature

with a sling psychrometer.

6. Refer to Table 4. Find air temperature entering out

door coil and wet-bulb temperature entering indoor

coil. At this intersection note the superheat.

7. Refer to Table 5. Find superheat temperature and

suction pressure, note suction line temperature.