Step 1, Site preparation, Step 2 – Carrier ASPB07-1SI User Manual

Page 6: Fuel hook up & check for leaks, Mm wsm, Fahrrctt^w'xtl, Will bis\ will be \(fi^lliitg, Cutting, Reconfiguringthefuelsystem”\n

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

STEP 1

*

mm

wsm

B

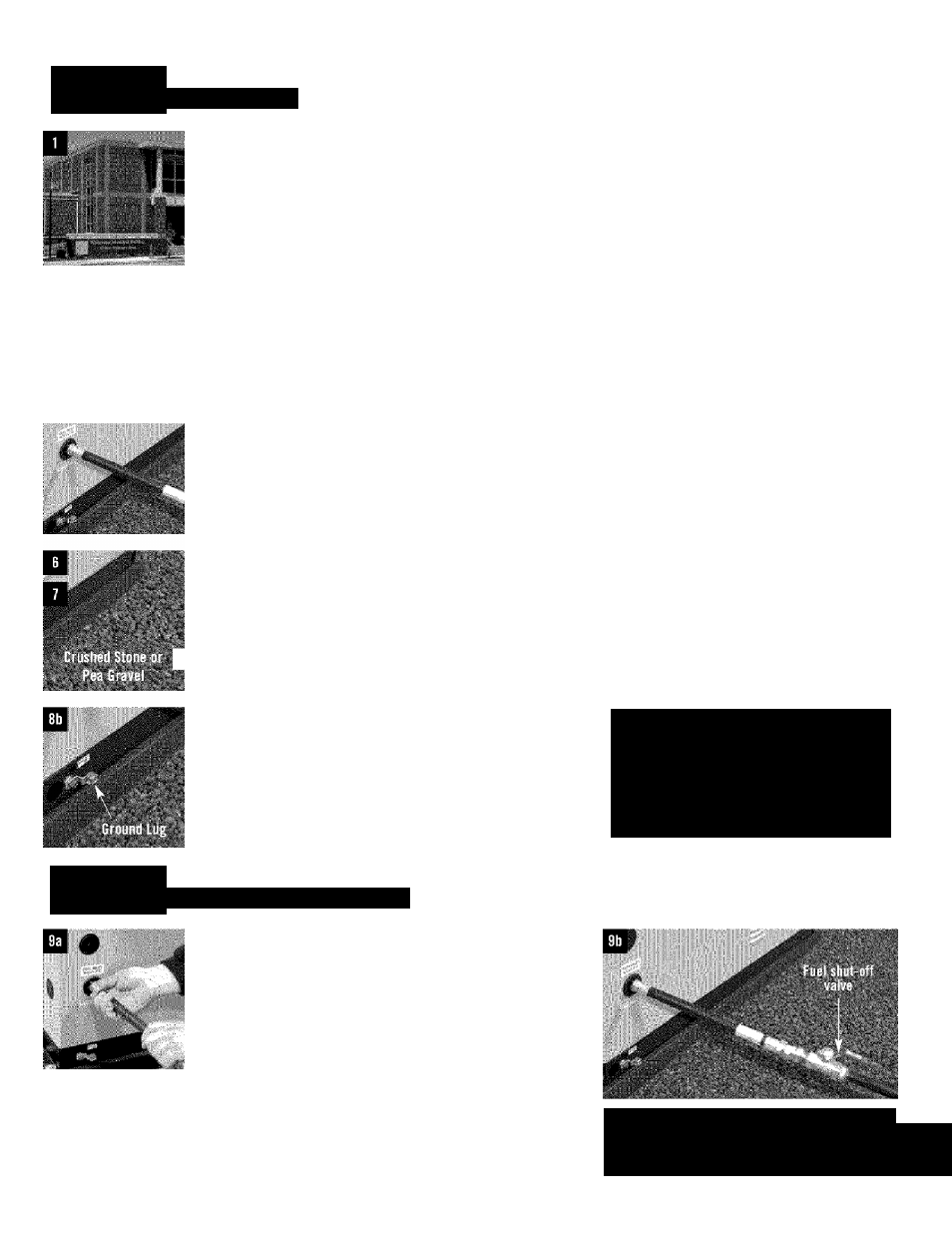

SITE PREPARATION

1.

It will be necessary to pay a visit to your local municipal offices

to apply for a building permit. Building permits are necessary to

ensure

proper

installation,

safety

and

adherence

to

all

local

building

code

specifications.

The

location

and

phone

number

can be found in the government section of your local phone book.

2.

Plan the location of your generator.

NOTE: Do not place the

generator directly under a window.

Select an area outside of

your home nearest your incoming gas service.

3.

Arrange

for

installation

of

rigid

gas

piping

(per

local

code

specifications) to the location where you intend to position your

generator. Fuel piping should include a fuel shut-off valve. The

termination

of

the

rigid

piping

should

be

aligned

with

the

generator fuel inlet located at the rear of the compartment.

4.

Clear an area 5-1/2 feet by 5 feet minimum of grass and vegetation

to a depth of 5 inches. This includes the distance the generator

should be set away from any structure (3 feet) and 6 inches beyond

the width and length of the generator mounting pad (48” Lx24” W).

NOTE: Local codes may supercede these requirements.

5.

Lay black poly-film to cover the area.

6.

Fill the area to ground level with pea gravel or crushed stone.

7.

Place the generator, which is attached to the mounting pad, on

the area you have just prepared.

‘ 8a. Drive an 8 ft. grounding rod into the ground to grade.

8b

STEP 2

Attach one end of the grounding strap (No. 12 AWG stranded

copper wire) to grounding rod and the other end to the grounding

lug (located at rear corner of unit). Make sure grounding rod and

strap are not exposed above ground level. (NEC code applies to

grounding method.)

NOTE: Generator mode switch should be placed in the “off”

position. Generator main line circuit breaker should be

switched to “off” or open position.

FUEL HOOK UP & CHECK FOR LEAKS

ITEMS YOU MUST PURCHASE:

B:attery

.-VAutani0tive.type/G:raup;26;

negaTive

Itojind. ntinimtiffl ;35t)i.CA .at T)'. F'/?: kW) .oral

ifiinimijnv.52S.tGA. at0'"Fi;T0iM; 13-kìi/ ani

40 Anjp (.7;kW);;ari7(3jAhlp :flDjkW^

T.5 TrW) jdouhjevpplejcirciJif: ;l)reaker;(iyiusT bf

Gornpat ifjfe I vvjfh'yoti ryma in. di stri butiovl pa nel;;);:

GfO:Uociing rod)with groundJh.g istrap : : j :: : : : :

•; PàdiockTTo.lock exfefnal:.cpnhec;tidndpx); 1 ;:

Crus-hpct Istòriero.r ;pea; gravel Tapproxfmately

1.0-1.2 cLi.hic feet)'-. :/■■ ■■. '

Black. p.cily-t.ii:m ór othe:r wegetatipn. blDcking

fahrrctt^W'xtL' ^............... ' "

Silicone Caulk i

Pipe.: sea la nt . ' (suita bTe. 1 forv ga.sepus Tuet >

connections}. -

:C-'.V.;V'.r

.■ .■ j

Fasteners: (to hiount externaToonnection ^brscs

a.n.d;.-automatic ■ tvansterIswitcb with: builtr«1,:

emergency IqadlcehteflVjl '.■■t-'t-' .-'j' .■'.■ jt j j j j

TOOLS REQUIRED:

Dr i lb driiTti

will bis\

Will be \(fi^lliitg

ti/?f7

cutting},

open-endj wrenches.: orlfidjusta.b.le.

wrenches.: Isocketi wreh.ches. or: :niut Vdriivers.:

standard and;Phil.lfps screwdrivers., level,: sledge:

hammer,

xhannel-tock:

plierstspavie.

/shovel.:

pehciT.a:nd.;sa:fe:ty goggles,/////////■■

PLEASE NOTE:

Natural gas pressure to the fuel

inlet on the generator must be 5 - 7” W.C. (0.18 to

0.25 psi). LP gas pressure to the fuel inlet on the

generator must be 10 -12" W.C. (0.36 to 0.43 psi)

A primary regulator must be used if unit is

connected to an LPfuel tank (Primary regulator is

not supplied).

9a.

Make

the

connection

between

the

rigid

fuel

piping

and

the

generator using the supplied threaded flexible fuel line. The flex

hose should be straight.

Do not bend the hose in place of using

pipe elbows.

Use a pipe sealant suitable for gaseous fuel

connections.

Check

connections

for

leaks

by

opening

manual

fuel shut-off valve and swab or spray connections with soapy

water. If a leak exists the area will bubble with the presence of

the soapy water.

9b. It a leak is located, shut off fuel, and disconnect flexible piping.

Dry the threaded ends and reapply an adequate amount of pipe

sealant.

Reconnect

flexible

fuel

line,

open

fuel

supply

and

recheck for leaks. If leak still exists, repeat step 9b.

Qonverting to LP gas

From the factory, units are set-up for natural gas

operation. To convert for operation on LP gas refer to

“Reconfiguringthefuelsystem”\n

the

Owner’s Manual.