Connecting the loads – Winco ULTB4000C User Manual

Page 6

12024-00

6

60706-225

tor. However, due to engine and generator effi cien-

cies of 80 to 90%, the loss of power due to engine

driving accessories such as cooling fans, battery

charging alternators, etc., friction losses and slippage

in the drive pullies and belts, the general conserva-

tive rule of thumb allowing approximately two (2)

horsepower for every 1,000 watts of generator output

is much more realistic. For example, this 2,000 watt

generator output will require a 4 or 5 H.P. engine

for full output, good speed/voltage regulation, and

satisfactory load performance. When determining the

prime mover/generator pulley ratio to drive the gen-

erator at the correct operating speed, bear in mind

that the power rating of most prime movers (usually

an engine) varies with the speed. It produces more

power at higher speeds, less when slowed. The

prime mover must be run fast enough to reach the

desired horsepower for good generator operation.

The drive belt system must be of adequate size and

must be tight enough to power the generator without

slippage. Be careful not to overtighten to the extent

that it puts excessive strain on the bearings. Doing

so can cause bearing failure and other possible dam-

age to the generator.

Alignment of the generator to the prime mover is

important. Misalignment of the pulleys will cause ex-

cessive belt and pulley wear and unnecessary stress

on the prime mover.

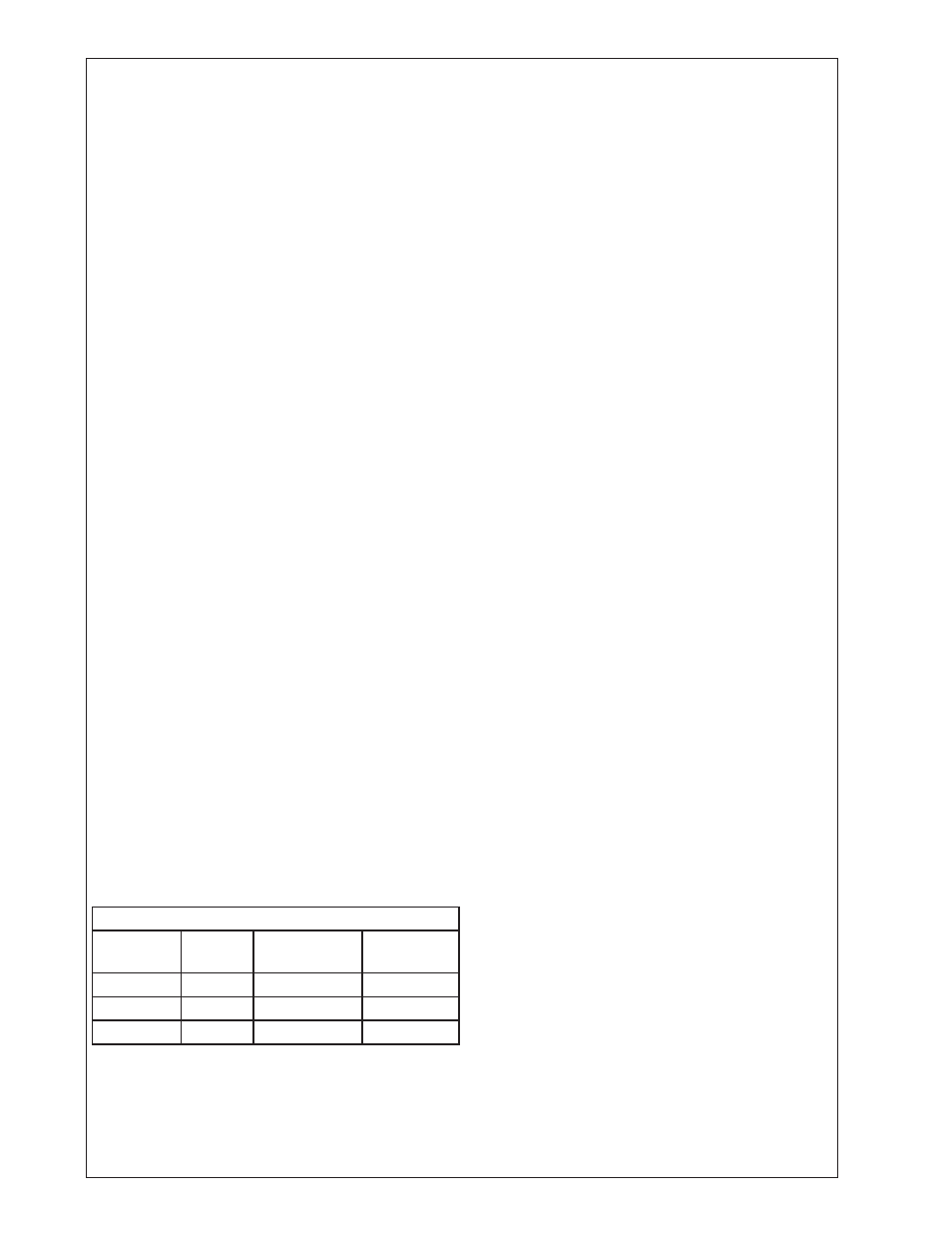

The following table shows the effect of various oper-

ating speeds and electrical loads on a typical gen-

erator when matched and mounted to an adequate

prime mover.

Although individual units and models may vary

slightly, the normal voltage and frequency of typical

60 cycle engine-driven generators described in this

manual are approximately as follows when powered

by a typical prime mover (engine) run fi rst with no

load applied, then at half the generator capacity and

fi nally when loaded to its full capacity as rated on the

nameplate.

LOAD VS. OUTPUT

Generator

Load*

Speed

(RPM)

Frequency

(Hz)

Voltage

None

3690

61.5

129V

Half

3600

60.0

120V

Full

3510

58.5

115V

* NOTE: Required generator speed must be main-

tained at 3600 +/- 90 RPM under all load conditions.

All engines have a tendency to slow down when

a load is applied. The governor on the engine is

designed to hold the engine speed nearly constant.

When the electrical load connected to the genera-

tor is increased, the engine is more heavily loaded

and as a result the speed drops slightly. This slight

decrease in speed together with the natural “voltage

drop” within the generator itself due to load current

and heating of the windings, results in a slightly

lower voltage than when the generator is running

idle.

The normal slight variations in speed also directly

affect the frequency of the output current. This

frequency variation has no appreciable effect in the

operation of most loads (such as motors, lights and

most small appliances). However, timing devices

and clocks will not keep perfect time unless the en-

gine can keep the generator running at exactly 3600

RPM at all times. Since this is not usually possible,

minor time errors in clocks occur.

The speed of the engine is usually adjusted so that

the generator produces proper voltage. If the adjust-

ment is made “cold,” set the voltage a little higher

than normal since it will drop a few volts as the

generator warms up.

NOTE: When operating continuously at full load the

generator shell becomes very warm. It will be un-

comfortable to the touch. This is normal for any high

performance inherently regulated generator. Output

voltage should be checked periodically to ensure

proper operation of the generator and appliances.

CAUTION: EQUIPMENT DAMAGE

Low voltage may damage any motors or appliances

connected to it. Running the generator at exces-

sively high speeds results in too high voltage which

will also damage electrical devices connected to it.

Excessively high speed may also cause damage to

the generator armature windings.

CONNECTING THE LOADS

Applying The Load - A short warm-up time will

permit the engine to work more effi ciently when the

load is applied and will reduce the wear and extend

its life. Receptacles have been provided on the end

cover to connect the loads on this generator.

CAUTION: EQUIPMENT OVERLOAD

Keep the generator load within the generator and re-

ceptacle nameplate rating. Overloading may cause

damage to the generator and/or the loads.

Most electric tools and appliances will have the volt-

age and amperage requirements on their individual

nameplates. When in doubt consult the manufactur-

er or a local electrician. The nameplate amperage