Testing policy, Description, Unit capabilities – Winco ULTB4000C User Manual

Page 4: Generator connections, Starting electric motors

12024-00

4

60706-225

TESTING POLICY

Before any generator is shipped from the factory, it

is fully checked for performance. The generator is

loaded to its full capacity, and the voltage, current

and frequency are carefully checked.

Rated output of generator is based on engineering

tests of typical units, and is subject to, and limited

by, the temperature, altitude, fuel, and other condi-

tions specifi ed by the manufacturer of the applicable

engines.

DESCRIPTION

The generator is a 3600 rpm two bearing, belt driv-

en, brushless, revolving fi eld design. The generator

is self excited and inherently regulated to +/- (plus or

minus) 7% - no load to full rated load. It can be op-

erated under any load within its rating without being

damaged. The frequency regulation is determined

by the sensitivity of the customer supplied prime

movers’ governor. It is desirable to maintain this

speed to within 3 cycles variation (61.5 Hz - 58.5 Hz)

no load to full rated load (3690 rpm - 3510 rpm).

UNIT CAPABILITIES

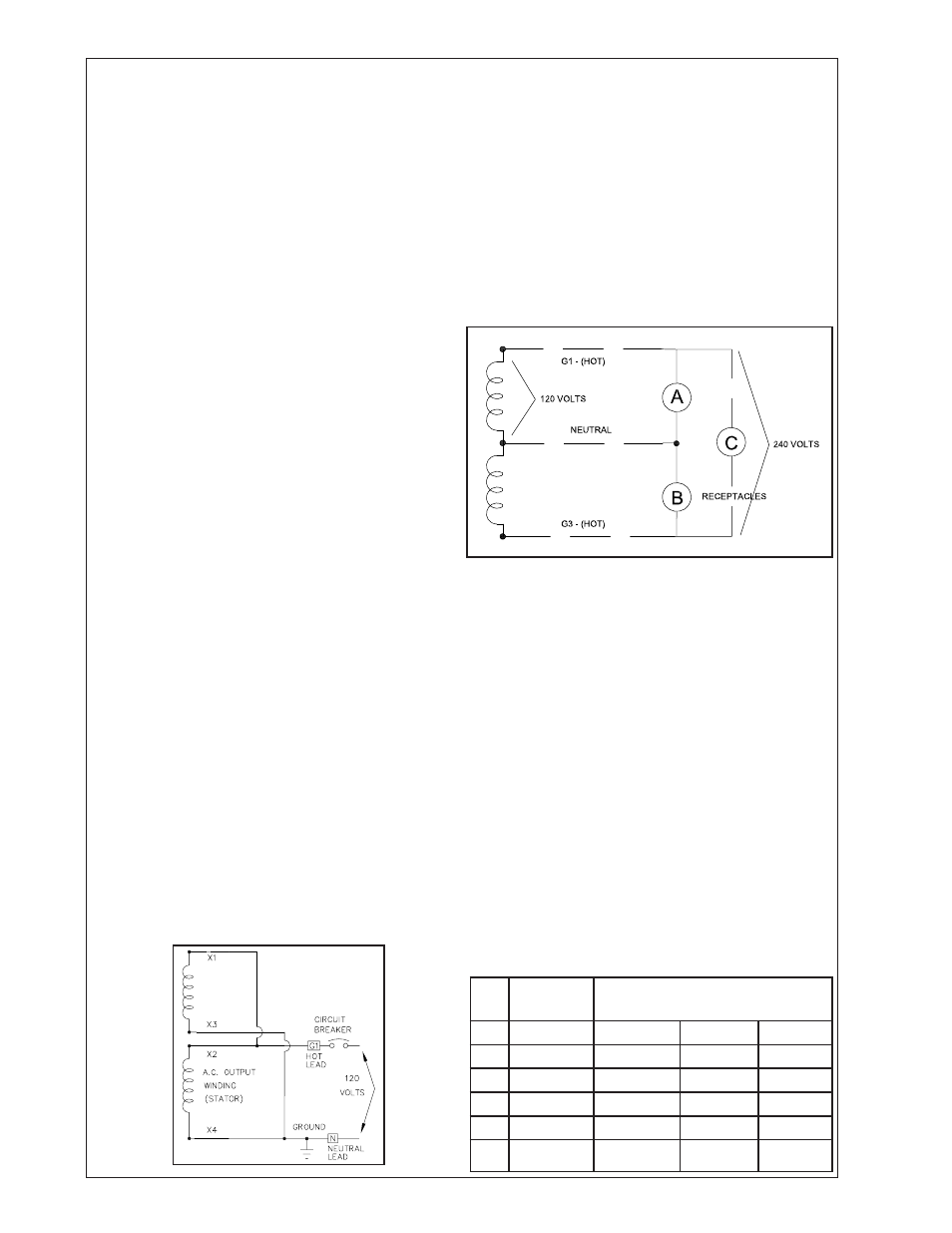

GENERATOR CONNECTIONS

This generator is designed for 120/240 volt alter-

nating current (AC). Two circuit breaker protected

duplex outlets and one 240 volt twist lock receptacle

are provided for connection to various loads. This

generator can be spun in either direction.

FULL POWER 120 VOLT ONLY

This generator can be converted to full power 120

volt only. Replacement of the circuit breaker and

receptacle is required. A 30 amp 1-pole circuit

breaker and a 3-wire 30 amp twist-lock receptacle is

recommended for full power applications. See wir-

ing schematic below.

Check the appliance or tool nameplate for the cur-

rent and voltage to insure compatibility. Although a

circuit breaker is provided, damage due to overload-

ing constitutes abuse and will not be warranted. Re-

fer to the generator nameplate for unit’s capabilities.

The diagram below represents a 4,000 watt genera-

tor. Only 2,000 watts at 120 volts (16.6 Amps) can

be taken from the generator at receptacle A and up

to 2,000 watts at 120 volts from receptacle C. On

an ordinary generator, CAUTION MUST BE EXER-

CISED TO PREVENT OVERLOADING EITHER OF

THE 120 VOLT CIRCUITS (A OR C).

STARTING ELECTRIC MOTORS

Electric motors require much more current (amps) to

start them than to run them. Some motors, par-

ticularly low cost split-phase motors, are very hard

to start and require 5 to 7 times as much current

to start them as to run them. Capacitor motors are

easier to start and usually require 2 to 4 times as

much current to start them as to run them. Repul-

sion Induction motors are the easiest to start and

require 1 1/2 to 2 1/2 times as much to start them as

to run them.

Most fractional horsepower motors take about the

same amount of current to run them whether they

are Repulsion Induction (RI), Capacitor (Cap), or

Split-Phase (SP) type. The chart below shows the

approximate current required to start and run various

types and sizes of 120 volt 60 cycle electric motors

under average load conditions.

HP

AMPS

RUNNING

STARTING AMPS

SP

CAP

RI

1/6

3.2

16 to 22

6 to 13

5 to 8

1/4

4.5

22 to 32

9 to 18

7 to 12

1/3

5.2

26 to 35

10 to 21

8 to 17

1/2

7.2

not made

14 to 29

11 to 18

1

13.0

not made

26 to 52

20 to 33