Winco PSS25000/A User Manual

Page 8

PAGE 6

60706-171

5076-10

Natural Gas

1

3

4

UNIT OFF

LINE PSI

7-11 in

7-11 in

4-6 oz.

4-6 oz.

STARTING

LINE PSI

7-11 in

7-11 in

4-6 oz.

4-6 oz.

NO LOAD

LINE PSI

7-11 in

7-11 in

4-6 oz.

4-6 oz.

FULL LOAD LINE PSI

7-11 in

7-11 in

4-6 oz.

4-6 oz.

LP LIQUID WITHDRAWAL

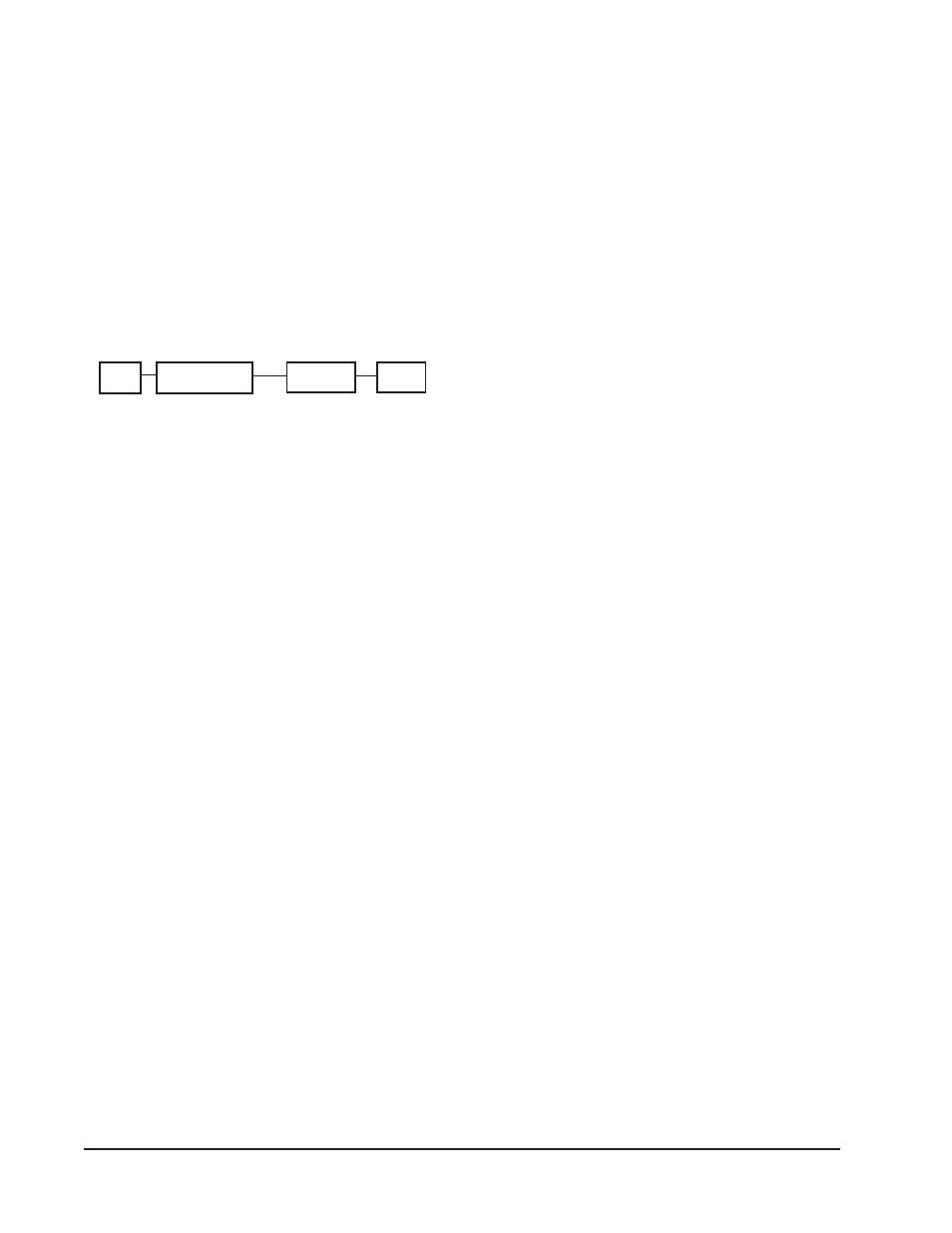

The following is a block diagram of a typical L/P Liquid

Withdrawal fuel system for the PSS25000.

Tank

Fuel Solenoid

Converter

Engine

1

2

3

4

Reference number 1 is the fuel tank. No regulator is

required but the tank must have a liquid withdrawal drop

tube installed in it and a liquid valve on the tank.

Reference numbers 2 through 4 are installed on the

engine generator set.

Liquid fuel is delivered from the tank directly to the fuel

solenoid on the generator at full tank pressure. This

system requires no pressure regulator be installed any

where in the system. The converter mounted on the

engine generator set will take the liquid fuel at tank

pressure and convert it to vapor at the proper delivery

rate.

LP/NG FUEL ADJUSTMENTS

**** CAUTION ****

Do not make any fuel adjustments or governor adjust-

ments until all pressure readings are in compliance with

specification. See fuel pressure charts (tables 1, 2, and

3).

NATURAL GAS (NG)

Due to variations in NG fuel characteristics and BTU

levels throughout the country, it may be necessary to

readjust the fuel mixture once the engine has been

installed and serviced.

**** CAUTION ****

Never make a fuel mixture adjustment on a unit when it is

stopped or running no load. A mixture adjustment is only

effective when the engine is operating under load.

ADJUSTMENT PROCEDURE

1. Insure the unit is operating with an 80 to 100% load

or at the highest anticipated load.

Note: The mixture adjustment is located on the carbure-

tor just behind the fuel inlet hose. This mixture

adjustment is a partial turn, lean to rich, load block.

2. Begin making a mixture adjustment. Adjustments

should be made very slowly. Adjust back and forth until

the engine is running as smooth as possible.

3. The PSS25000 is equipped with an electronic

governor which requires no speed adjustment.

FUEL TYPE CONVERSION

If it should be necessary to change the type of fuel used

after a unit is received, the following procedures are

provided.

NATURAL GAS TO PROPANE

1. Turn off fuel supply.

2. Remove the fuel line from the carburetor at the

demand regulator.

3. Remove the cap on the upright column of the

regulator. This will expose the pressure spring adjusting

screw. Back off the spring adjusting screw so there is just

enough room to replace the cover. Replace the cover.

4. Invert the regulator so it is positioned with the column

pointing down.

5. Reconnect the fuel line at the regulator.

6. Remove the 1/8 NPT plug (the one closest to fuel

solenoid) located on what is now the top of the regulator.

Connect a fuel pressure meter or a manometer where

the plug has been removed. Move the generator control

switch to the run position. As the unit starts to crank the

fuel solenoid will open and you should get a pressure

reading of between 4 to 6 ounces (7 to 11 inches of water

column).

7. If the pressure is correct, remove the meter and

reinstall the pipe plug.

8. You are now ready to make the final fuel mixture

adjustment. Refer to adjustment section in this manual.

PROPANE TO NATURAL GAS

1. Turn off fuel supply.

2. Remove the fuel line from the carburetor at the

demand regulator.

3. Invert the regulator so the column is in the upright

position. Remove the cap on the upright column of the

regulator. This will expose the pressure spring adjusting

screw. Turn the screw all the way out (CCW) and then

back in (CW) about 8 turns. The plug should be approxi-

mately half way down for initial starting.

4. Reconnect the fuel line at the regulator.

5. Remove the 1/8 NPT plug (the one closest to fuel

solenoid) located on what is now the bottom of the

regulator. Connect a fuel pressure meter or a manometer

where the plug has been removed. Move the generator

control switch to the run position. As the unit starts to

crank the fuel solenoid will open and you should get a

pressure reading of between 4 to 6 ounces (7 to 11

inches of water column).