Winco PSS8B4W/A User Manual

Page 7

PAGE 5

4023-50

60706-166

**** CAUTION ****

Be careful when sealing gas joints. Excessive sealing

compound can be drawn into the solenoid, regulator or

carburetor causing an engine malfunction.

FUEL PRESSURE

L.P. & N.G. VAPOR FUEL

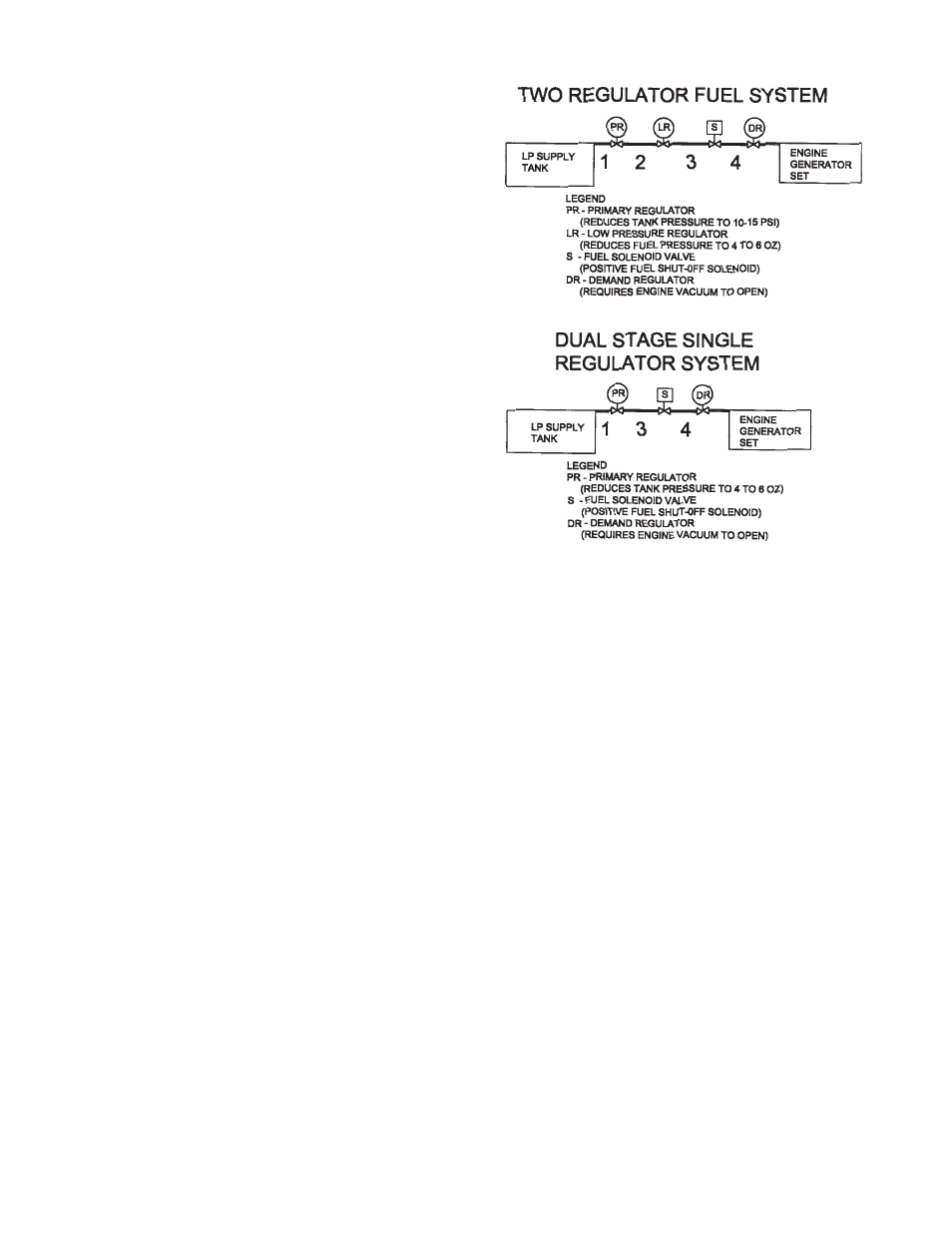

Correct fuel pressure cannot be stressed enough. The

most common cause for inoperative systems is an

inadequate or incorrect fuel pressure. Performance of

the engine is in direct relation to the correctness of the

fuel system. Shown below is a block diagram of a

typical L.P. or N.G. vapor fuel installation.

Notice the following tables give two (2) different units of

measuring fuel pressure. The first and most accurate is

the use of a simple water manometer. A manometer is

calibrated in inches of water column. The second is with

a pressure gauge calibrated in ounces per square inch.

Reference numbers 1 through 3 in the block diagrams

above are system parts supplied by customer.

Reference number 4 is the engine generator set.

Below is a table of the fuel pressure reading at each

reference in the system.

Fuel Pressure Table

Single Regulator (L.P. Vapor only)

1

3 4

UNIT OFF

TANK PSI

7-11 in

7-11 in

4-6 oz

4-6 oz

STARTING

TANK PSI

7-11 in

7-11 in

4-6 oz

4-6 oz

NO LOAD

TANK PSI

7-11 in

7-11 in

4-6 oz

4-6 oz

FULL LOAD TANK PSI

7-11 in

7-11 in

4-6 oz

4-6 oz

Two (2) Regulator System (L.P. Vapor only)

1

2

3

4

UNIT OFF

TANK PSI

10-15 lbs 7-11 in

7-11 in

4-6 oz

4-6 oz

STARTING

TANK PSI

10-15 lbs 7-11 in

7-11 in

4-6 oz

4-6 oz

NO LOAD

TANK PSI

10-15 lbs 7-11 in

7-11 in

4-6 oz

4-6 oz

FULL LOAD TANK PSI

10-15 lbs 7-11 in

7-11 in

4-6 oz

4-6 oz

Natural Gas

1

3

4

UNIT OFF

LINE PSI

7-11 in

7-11 in

4-6 oz

4-6 oz

STARTING

LINE PSI

7-11 in

7-11 in

4-6 oz

4-6 oz

NO LOAD

LINE PSI

7-11 in

7-11 in

4-6 oz

4-6 oz

FULL LOAD LINE PSI

7-11 in

7-11 in

4-6 oz

4-6 oz

LP/NG FUEL CONVERSION

These generator sets are factory tested on Natural Gas

and will require no modifications for normal operation on

Natural Gas. The carburetion system has been preset

and anti-tamper plugs have been installed in the carbure-

tor as required by EPA.

If you are operating on LP fuel you will have to make

the following modification: On the left side of the engine,

above the starter there is a small two wire connector

lying loose. This connector has to be plugged into the

mating two wire connector coming out of the carburetor

area on the left side of the unit. This connection will

engage an orifice in the carburetor allowing the unit to

operate on Liquid Propane Vapor fuel. NO other

adjustments are required.

If you are reinstalling a unit that has been operat-

ing on Liquid Propane vapor and you now want to

operate it on Natural Gas all that you will need to do is

unplug this connector.

LUBRICATION

Before starting the engine, fill the crankcase with the

proper weight/grade of oil, as recommended by the

engine manufacturer’s maintenance instructions. The

necessity of using the correct oil, and keeping the

crankcase full cannot be over emphasized.