Unpacking, Unit capabilities – Winco HPS12000HE User Manual

Page 5

Page 3

60707-115

6190-00

The figures given above are for an average load such as a

blower or fan. If the electric motor is connected to a hard

starting load such as an air compressor, it will require more

starting current. If it is connected to a light load, or no load

such as a power saw, it will require less starting current.

The exact requirement will also vary with the brand or

design of the motor.

Self-excited generators respond to severe overloading

differently than the power line. When overloaded, the

engine is not able to supply enough power to bring the

electric motor up to operating speed. The generator

responds with high initial starting current, but the engine

speed drops sharply. The overload may stall the engine. If

allowed to operate at very low speeds, the electric motor

starting winding will burn out in a short time. The generator

winding might also be damaged.

CAUTION: EQUIPMENT DAMAGE

RUNNING THE GENERATOR SET UNDER THESE

CONDITIONS MAY RESULT IN DAMAGING THE

GENERATOR STATOR AS WELL AS THE MOTOR

WINDING.

Because the heavy surge of current required for starting

motors is required for only an instant, the generator will not

be damaged if it can bring the motor up to speed in a few

seconds of time. If difficulty is experienced in starting

motors, turn all other electrical loads off and if possible

reduce the load on the electric motor.

UNPACKING

CAUTION: EQUIPMENT DAMAGE

THIS UNIT HAS BEEN SHIPPED WITHOUT OIL.

Failure to maintain the engine oil at the proper level will

result in serious engine damage.

When you unpack your new ENGINE GENERATOR be sure

to remove all the information sheets and manuals from the

carton.

1. This power plant was in good order when shipped.

Inspect the power plant promptly after receiving it. If

damage is noted, notify the transportation company

immediately; request proper procedures for filing a

“concealed damage” claim. Title to the equipment

and responsibility for filing a claim rests with you

when a generator is sent F.O.B. shipping point. Only

you can legally file a claim.

2. Before proceeding with the preparation of your new

engine generator set for operation, take a couple of

minutes to insure that the unit you have received is

the correct model and review the specification pages

in this manual to insure that this unit fits your job

requirements.

3. After removing the engine generator from the carton

locate and remove the shipping strap attached to the

generator shock mount. See attached tag for

removal instructions.

UNIT CAPABILITIES

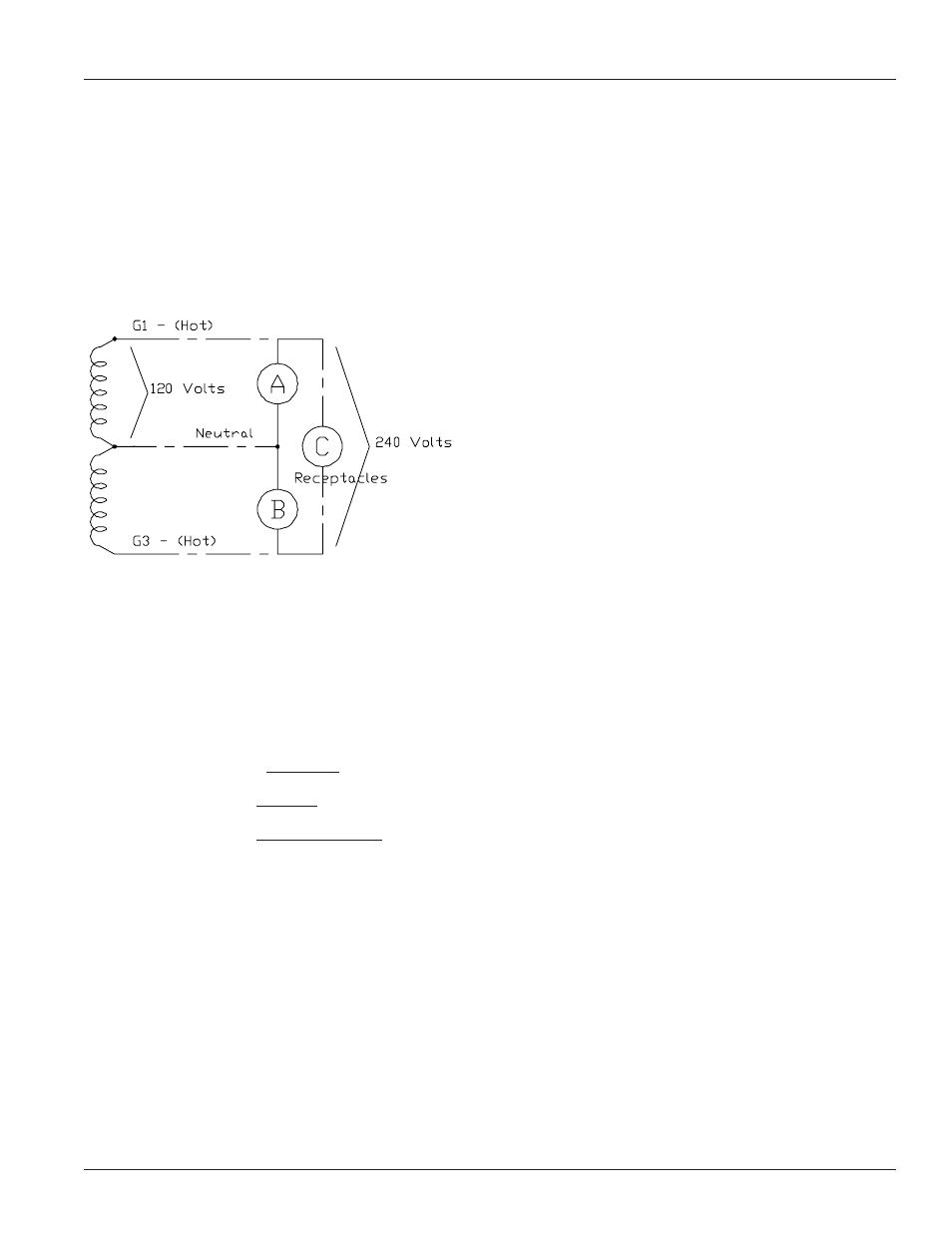

Generator Connections - The diagram below represents a

typical 5500 watt generator. Receptacles A and B are the

two 120 Volt duplex receptacles. Up to 2750 watts at 120

volts (22.9 Amps) can be taken from the generator at each

of the receptacles. This generator produces 120 and 240

volt, 60 Hz (Hertz), AC (Alternating Current).

CAUTION: EQUIPMENT DAMAGE

CAUTION MUST BE EXERCISED TO PREVENT

OVERLOADING EITHER OF THE GENERATORS

120 VOLT OUTPUT CIRCUITS (A OR B).

Check the appliance or tool nameplates for the current and

voltage to insure compatibility. Remember that power taken

from receptacle C reduces the power available at both A

and B. Any remaining 120 volt loads should be equally

divided between A and B. Failure to split the load will cause

permanent damage to the stator. Although circuit breakers

are provided, damage due to overloading constitutes abuse

and will not be warranted. Refer to the generator nameplate

for your unit's capabilities.

Starting Electric Motors - Electric motors require much

more current (amps) to start them than to run them. Some

motors, particularly low cost split-phase motors, are very

hard to start and require 5 to 7 times as much current to

start them as to run them. Capacitor motors are easier to

start and usually require 2 to 4 times as much current to

start them as to run them. Repulsion Induction motors are

the easiest to start and usually require 1 1/2 to 2 1/2 times

as much to start them as to run them.

Most fractional horsepower motors take about the same

amount of current to run them whether they are of

Repulsion-Induction (RI), Capacitor (Cap), or Split-Phase

(SP) type. The chart below shows the approximate current

required to start and run various types and sizes of 120 volt

60 cycle electric motors under average load conditions.

RUNNING

STARTING AMPS

HP

AMPS SP

CAP

RI

1/6

3.2

16 TO 22

6 TO 13

5 TO 8

1/4

4.5

22 TO 32

9 TO 18

7 TO 12

1/3

5.2

26 TO 35

10 TO 21

8 TO 17

1/2

7.2

NOT MADE 14 TO 29

11 TO 18

1

13.0

NOT MADE 26 TO 52

20 TO 33