Winco HPS12000HE/F User Manual

Page 8

3240-10

8

60706-236

Natural Gas

2

3

4

UNIT OFF

LINE PSI 7-11 in

7-11 in

4-6 oz

4-6 oz

STARTING

LINE PSI 7-11 in

7-11 in

4-6 oz

4-6 oz

NO LOAD

LINE PSI 7-11 in

7-11 in

4-6 oz

4-6 oz

FULL LOAD

LINE PSI 7-11 in

7-11 in

4-6 oz

4-6 oz

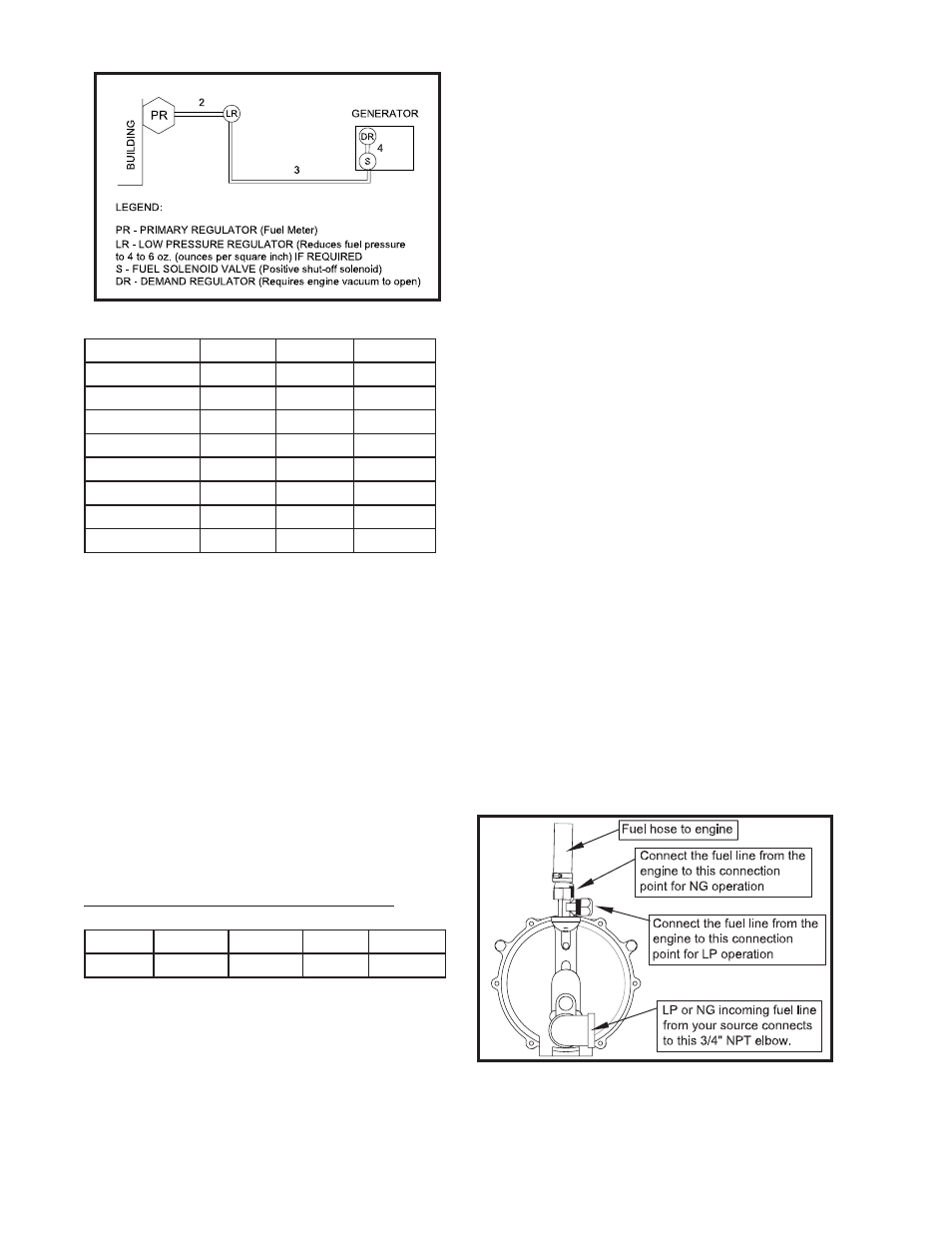

Remember that whichever fuel delivery system or

type of vapor fuel used, the fuel pressure at the

demand regulator installed on the engine generator

must be between 4 and 6 oz. (7-11 inches of water

column). Any lower pressure and the unit will starve

for fuel under load. Any higher and the unit will ‘fl ood’

when attempting to start.

LP TANK SIZING

The tank sizes shown below are the smallest recom-

mended tank sizes based on the outside temperature.

Once above this minimum acceptable size, the size of

L.P. tank used will generally depend on how long you

want the unit to run without refi lling. Keep in mind

the colder it gets the slower L.P. will vaporize. This

is the reason for the larger tanks at low temperature.

Minimum sizing is not based on running time.

Temp f.

60 deg

30 deg

0 deg

-20 deg

150 gal

250 gal

500 gal

1000 gal

CHANGING FUEL TYPES

These engine generator sets are designed to run

on three different fuels; gasoline, natural gas or LP

vapor. They may be easily changed from one fuel to

another.

FROM GASOLINE TO LP/NG

1. With the engine running turn off the gasoline

fuel valve.

2. Run the engine until it runs out of fuel.

3. Remove the plastic insert from the demand

regulator.

4. Install a locally approved fl exible fuel line.

5. Connect the LP/NG vapor fuel line to the fl ex-

ible fuel line. You can’t connect the black iron

pipe dir

6. All three units have two different hose fi ttings

on the top of the demand regulator. One is for

LP and one is for Natural Gas. Make sure the

hose is attached to the proper fi tting. See the

picture below.

7. Turn on the vapor fuel.

8. Start the engine.

9 . Apply the load to the generator.

FROM LP/NG TO GASOLINE

1. With the engine running turn off the LP/NG

fuel supply.

2. Run the engine until it runs out of fuel.

3. Remove

the

fl exible fuel line from the demand

regulator.

4. Reinstall the plastic insert in the regulator.

5. Check to be sure the gasoline fuel valve is off.

6. Fill the gasoline fuel tank.

7. Turn on the gasoline fuel valve.

8. Start the engine.

If the optional FUEL SOLENOID kit has been in

stalled on the unit all vapor fuel connection will be

made at the 12 volt gas valve.