Assembly instructions – Vogelzang BK150E User Manual

Page 4

Page 4

/ BK150E

Vogelzang International Corp.

VGZ-024 / 20120410.2

ASSEmblY INSTRUCTIONS

tools

required

CAUTION: STOVE IS HEAVY. mAKE SURE YOU

HAVE ADEqUATE HELP AND USE PROPER

LIFTING TECHNIqUES wHEN ASSEmBLING KIT

AND wHENEVER mOVING STOVE.

Refer to diagram and parts lists at back of this manual.

1. Remove parts from inside of carton. Parts

include: one damper collar (#1), two leg sets (#2),

one door/frame assembly (#3–16) and one hard-

ware pack (#7).

2. Stand barrel on end with plug facing up. Position

door between the large and small plugs with the

large plug at the 12 o’clock position.

NOTE: On 30 gallon barrels, use end without plugs

for mounting door.

3. Open the feed door and trace around the opening

using a scribe or marking pencil.

4. Open the ash door and trace around the opening

using a scribe or marking pencil.

5. Remove the door assembly from the barrel end.

6. Cut the opening for the feed door and ash door (fig.

1) using either a sabre saw or a reciprocating saw

with a metal blade. De burr opening with metal file.

materials

required

(NOTE: The following items are NOT included with your stove)

10. Cut the flue pipe opening using a sabre saw

or reciprocating saw. De burr opening with metal file.

11. Reposition the damper collar over the newly created

opening. Mark and drill the mounting holes using

a 1/4” bit. De burr holes with metal file. Attach the

damper collar using nuts and bolts provided with

kit.

metal File

Drill: Hand or Electric

1/4” dia. Drill Bit

#2 Phillips Screwdriver

10mm Nut Driver or

Ratchet with 10mm Socket

(for Stove Bolts)

Safety Glasses

Safety Gloves

Pencil or scribe

6 foot Folding Rule or

Tape measure

Sabre or Reciprocating Saw

with metal cutting blade

Tin Snips

Steel Barrel(s): Use only 30–55

gal. closed head-style steel

barrel(s).

Flooring Protection: Install on

non-combustible (soil or con-

crete) floor. Non-combustible

floor protection must be pro-

vided under any connector pipe

extending 2” on either side.

Chimney Connector Pipe:

round 6” dia. minimum 24

mSG black or 26 mSG blue

steel stove pipe (straight and/

or elbow(s) as required).

1/2” Sheet metal Screws.

Chimney: Existing 6” Lined ma-

sonry Chimney or 6” Inside Dia.

listed Type HT chimney.

Furnace Cement (manufacturer

recommends Rutland Code 78

or equivalent).

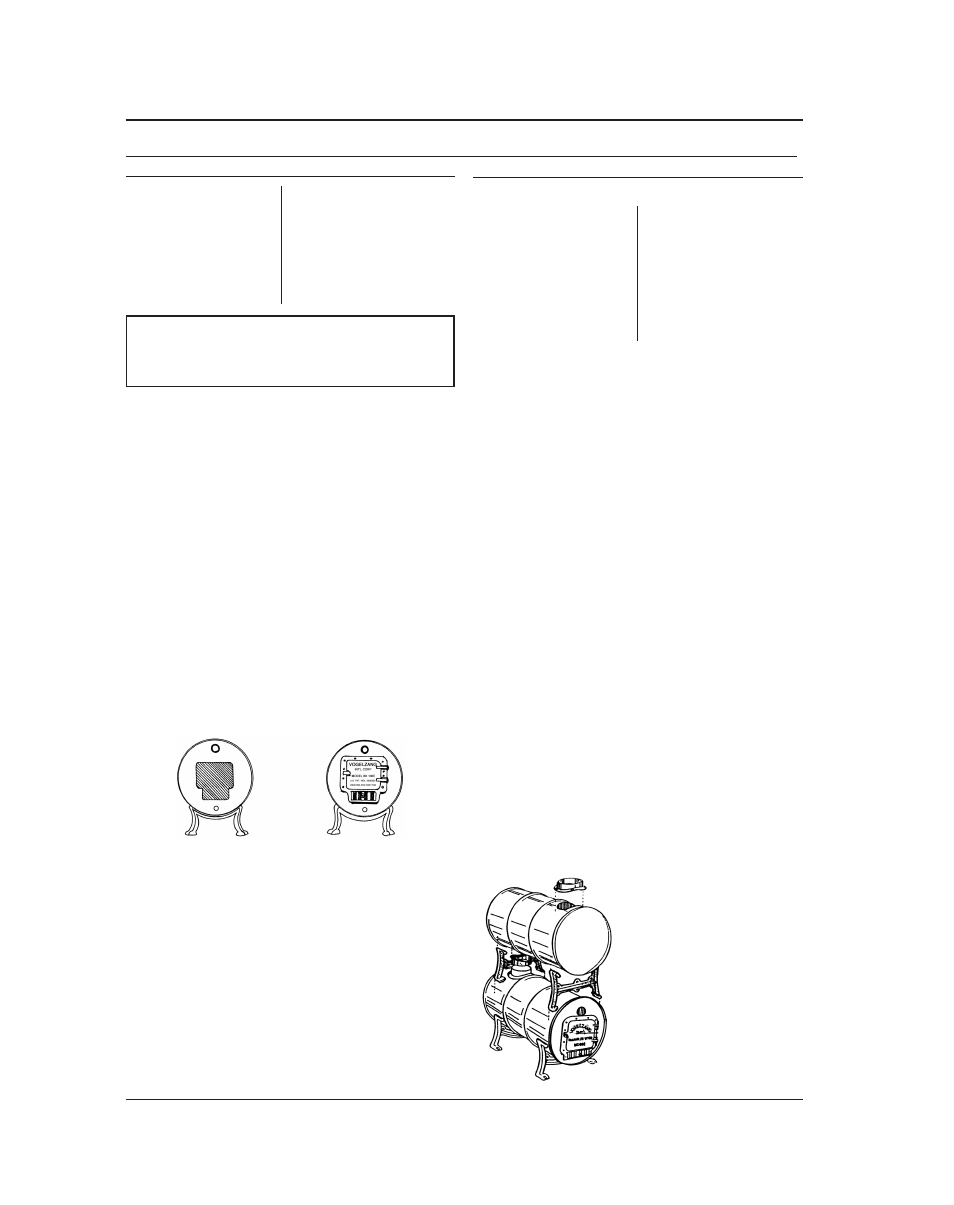

Fig. 1 – Cut opening in end of barrel, drill mounting

holes and install door assembly.

Double Barrel Stove Kit model BK50E

1. After lower barrel has been assembled, place

adapter legs on top of bottom barrel. Mark holes,

drill and attach.

2. Place second barrel on top of lower barrel.

3. Align barrels, mark, drill and cut opening for damper

collar in the bottom of the top barrel to connect to

the damper/collar at rear of the lower barrel.

4. Attach damper collar to bottom of top barrel.

5. Align both barrels and place a piece of 6” blue/black

stove pipe between rear damper/collars of top and

bottom barrels.

6. Secure adapter legs

to top barrel.

7. On opposite (front)

end of top barrel,

mark, cut and attach

damper collar for

chimney connection

(fig. 2).

Fig. 2 – Double Barrel

Stove Kit BK50E

7. Set the door frame assembly over the newly created

holes. Mark and drill the mounting holes using a

1/4” bit. De burr opening with metal file. Attach the

assembly using nuts and bolts provided with kit.

8. With the door opening cut, you are now able to get

at the inside of the barrel to attach leg assemblies.

Center legs so barrel is stabilized and secure legs

to barrel.

9. Align damper/collar toward the rear of barrel. Us-

ing a scribe or marking tool, trace the throat of the

collar onto the barrel top.

NOTICE: Vogelzang International Corp . grants no warranty, stated or implied for the assembly, installation or

maintenance of your barrel stove kit and assumes no responsibility of any incidental or consequential damages .