Use and operation, Notes on operation, Connecting and starting operation – VACUUBRAND MPT 200 User Manual

Page 9: Notice

page 9 of 20

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999226 // 07/10/2011

Use and operation

Notes on operation

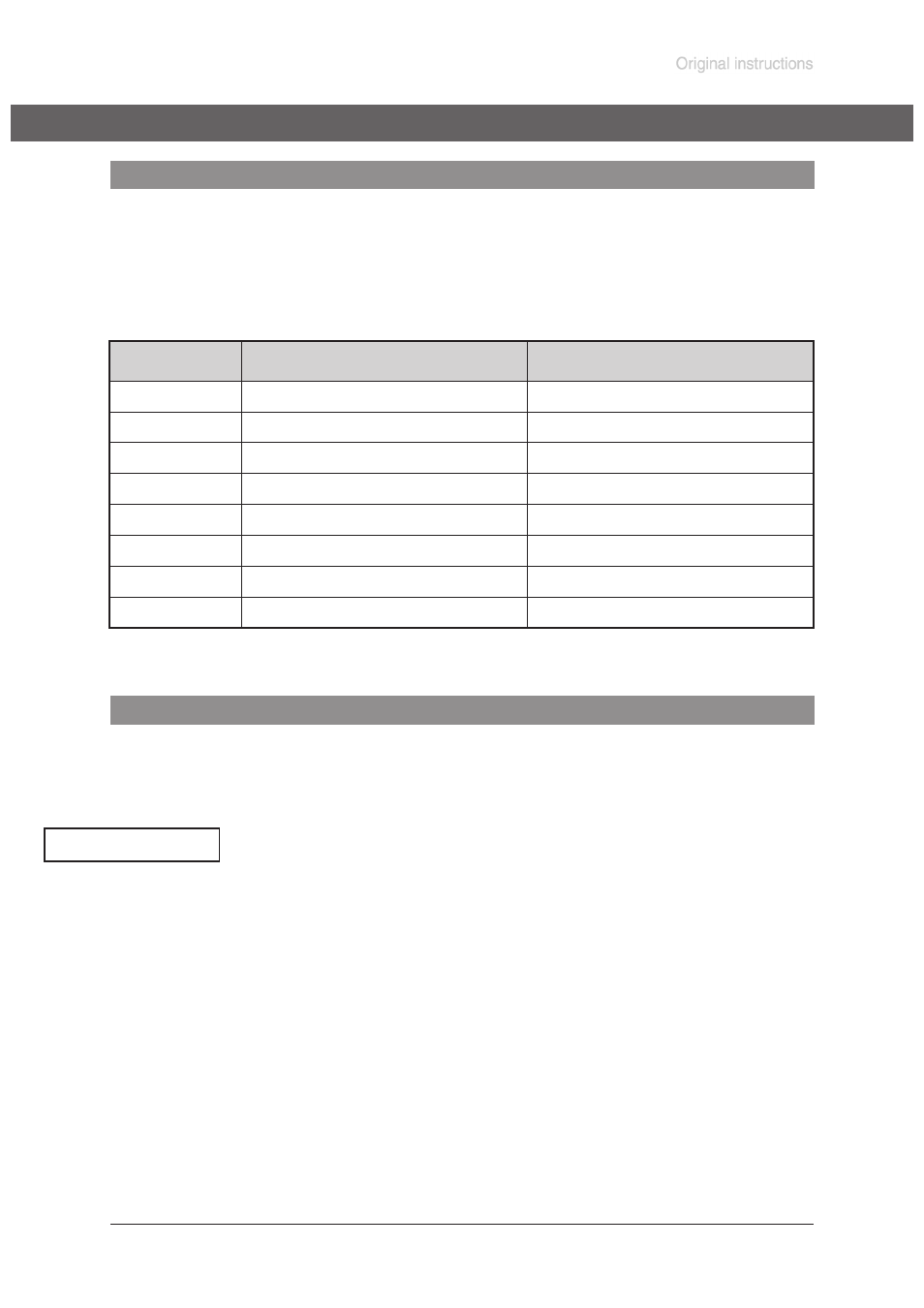

Gas

Correction factor cold cathode

Correction factor Pirani

Air / N

2

-

1.00

CO

2

0.74

0.89

H

2

2.39

0.58

He

5.93

1.02

Ne

3.50

-

Ar

0.80

1.59

Kr

0.60

-

Xe

0.41

-

The vacuum gauge head MPT 100 consists of two components: one cold cathode sensor and one Pirani

sensor. The pressure measurement is dependent on the gas type. The vacuum gauge head is factory-

set for operation with air / N

2

.

Use the following correction factors when working with different gases in the pressure range below 0.1

mbar:

Connecting and starting operation

Vacuum connection:

➨

Remove the protective cover and keep.

➨

Connect the vacuum gauge head via small flange to the vacuum application.

☞

The vacuum gauge head may be mounted in any orientation, though an orienta-

tion is to be preferred in which condensate cannot get into the measuring cham-

ber.

☞

Avoid contamination (oil/oil mist) of the measurement chamber when generating the vacuum with an

oil-filled vacuum pump.

☞

Do not mount the vacuum gauge head directly at the oil-sealed pump. The diameter of the pipelines

should be as large as possible.

☞

Inside a vacuum system where evaporation occurs (e.g. rotary evaporator) the vacuum is not uni-

form. Therefore choose carefully the position where to connect the vacuum gauge head.

☞

Condensate and deposits in the measuring chamber falsify the measurement result.

☞

Soiling and damage effect adversely the function of the vacuum gauge head.

☞

If residues occur or when working with aggressive or condensable substances, install a gas washing

bottle in front of the vacuum gauge head MPT 100.

Electrical connection / VACUU•BUS

Voltage supply and readout of the vacuum gauge head via VACUU•BUS line by the vacuum gauge

DCP 3000 using VACUU•BUS protocol. Maximum cable length inside buildings: 30m. Extension cable

VACUU•BUS 2m: order-no. 612552.

NOTICE