Prior to operation, Vacuu•bus – VACUUBRAND VSP 3000 User Manual

Page 13

page 13 of 18

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999159 / 22/07/2014

Prior to operation

➨

Connect gauge head by means of the VACUU•BUS line to a controller CVC 3000 or VNC 2 or to a

vacuum gauge DCP 3000.

➨

Connect the gauge head to the vacuum chamber by means of the small flange connection or a hose

connection. Avoid contamination (oil/oil mist) of the gauge head when generating the vacuum with an

oil-sealed vacuum pump.

☞

Do not mount the gauge head directly at the oil-sealed pump but close to the vacuum process. The

diameter of the vacuum lines should be as large as possible.

☞

Inside a vacuum system where evaporation occurs (e.g., rotary evaporator) the vacuum is not uni-

form (e.g., a condenser acts as pump or the vacuum in the pipeline is lower than in the system).

Therefore choose carefully the position where to connect the gauge head.

☞

Condensate and deposits at the gauge head falsify the measurement result.

☞

If residues occur or when working with aggressive or condensable substances, install a gas washing

bottle in front of the pressure gauge head.

☞

Mount the gauge head in such a position that condensate can not flow into it.

☞

If necessary, clean the gauge head.

VACUU•BUS

Readout of the pressure transducer via VACUU•BUS line by he controller CVC 3000 or VNC 2 or by

the vacuum gauge DCP 3000 using VACUU•BUS protocol (see instructions for use of vacuum control-

lers CVC 3000 or VNC 2 or of vacuum gauge DCP 3000). Maximum cable length inside buildings: 30m.

Extension cable VACUU•BUS 2m: order-no. 612552.

With the devices CVC 3000 and DCP 3000 it is possible to adjust and to configure the pressure trans-

ducer VSK 3000. (A configuration of the VSK 3000 e.g., to a different VACUU•BUS address, is required

if more than one pressure transducer are connected to a CVC 3000 or DCP 3000.)

Additional instructions for use regarding the configuration of pressure transducers or other

VACUU•BUS components are available upon request.

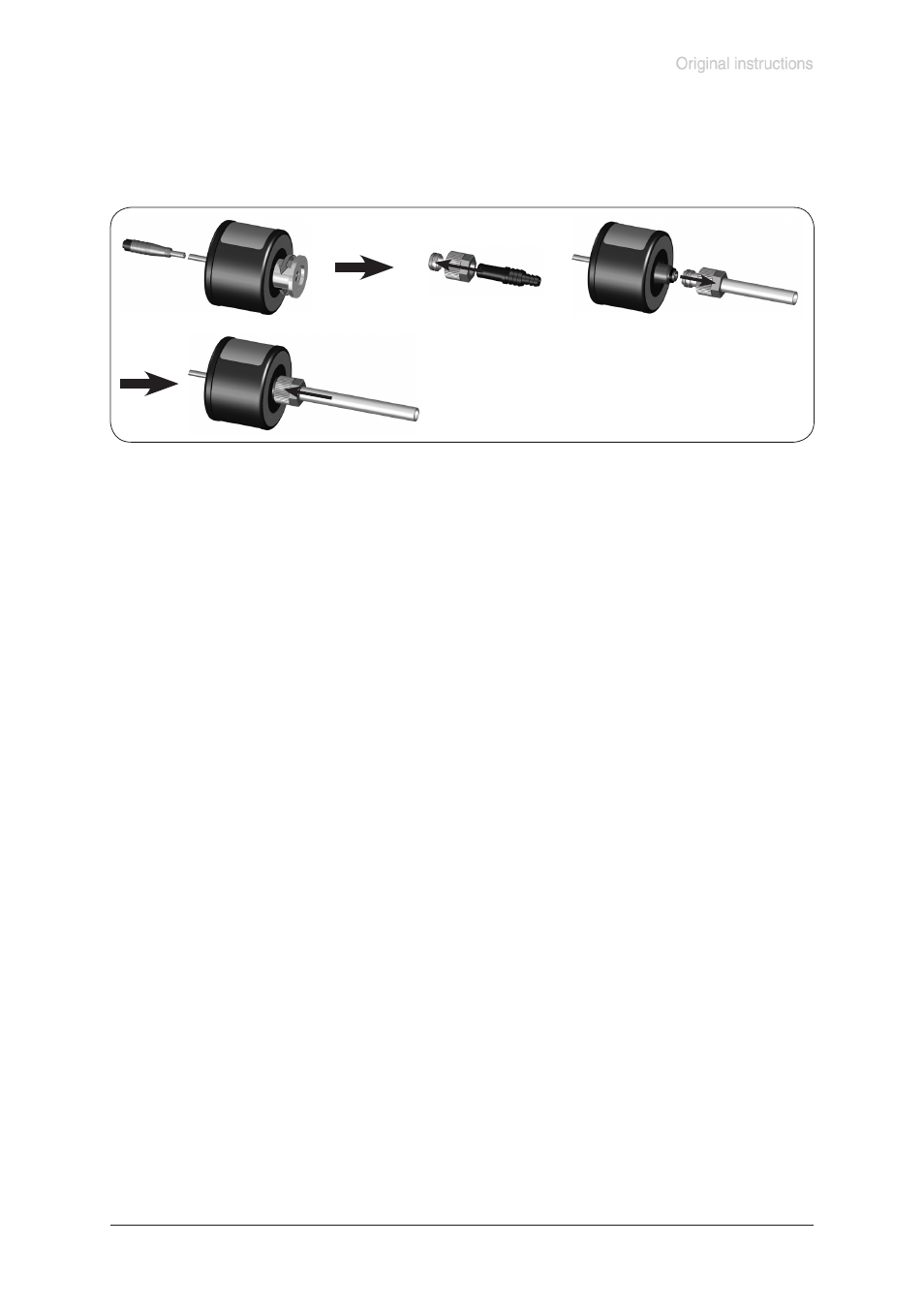

(1)

(2)

(3)

Installing the PTFE-tubing connection (PTFE-tubing ID: 8mm, OD: 19mm):

Unscrew the flange (using a 17 mm open-end wrench, if necessary) to expose the compression fitting

(1). Slip the compression nut, and then the ferrule, onto the PTFE-tubing (2). Slide the PTFE-tubing onto

the compression fitting on the VSK 3000 gauge head, and tighten the compression nut firmly finger-tight

(3).