Wetted parts, Pressure transducer vsk 3000, Operation principle of the vsk 3000 – VACUUBRAND VSP 3000 User Manual

Page 12: Changing the vacuum connector

page 12 of 18

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999159 / 22/07/2014

Wetted parts

Components

Wetted materials

VSK 3000

Sensor

aluminium oxide ceramics

Sensor housing, measurement chamber

PPS, glass fibre

Seal at sensor

chemically resistant fluoroelastomer

Hose nozzle

PP

Clamping ring

PA

Small flange

stainless steel or PP

VSP 3000

Sensor

aluminium oxide ceramics

Sensor housing, measurement chamber, small

flange

PBT, glass fibre / PUR

Hose nozzle / O-ring

PPS, glass fibre / FPM

Pressure transducer VSK 3000

We reserve the right for technical modification without prior notice!

Operation principle of the VSK 3000

The VSK 3000 is equipped with a capacitive pressure transducer with ceramic diaphragm to measure

the actual pressure

independent of the gas type and depending on the vacuum, i. e. absolute.

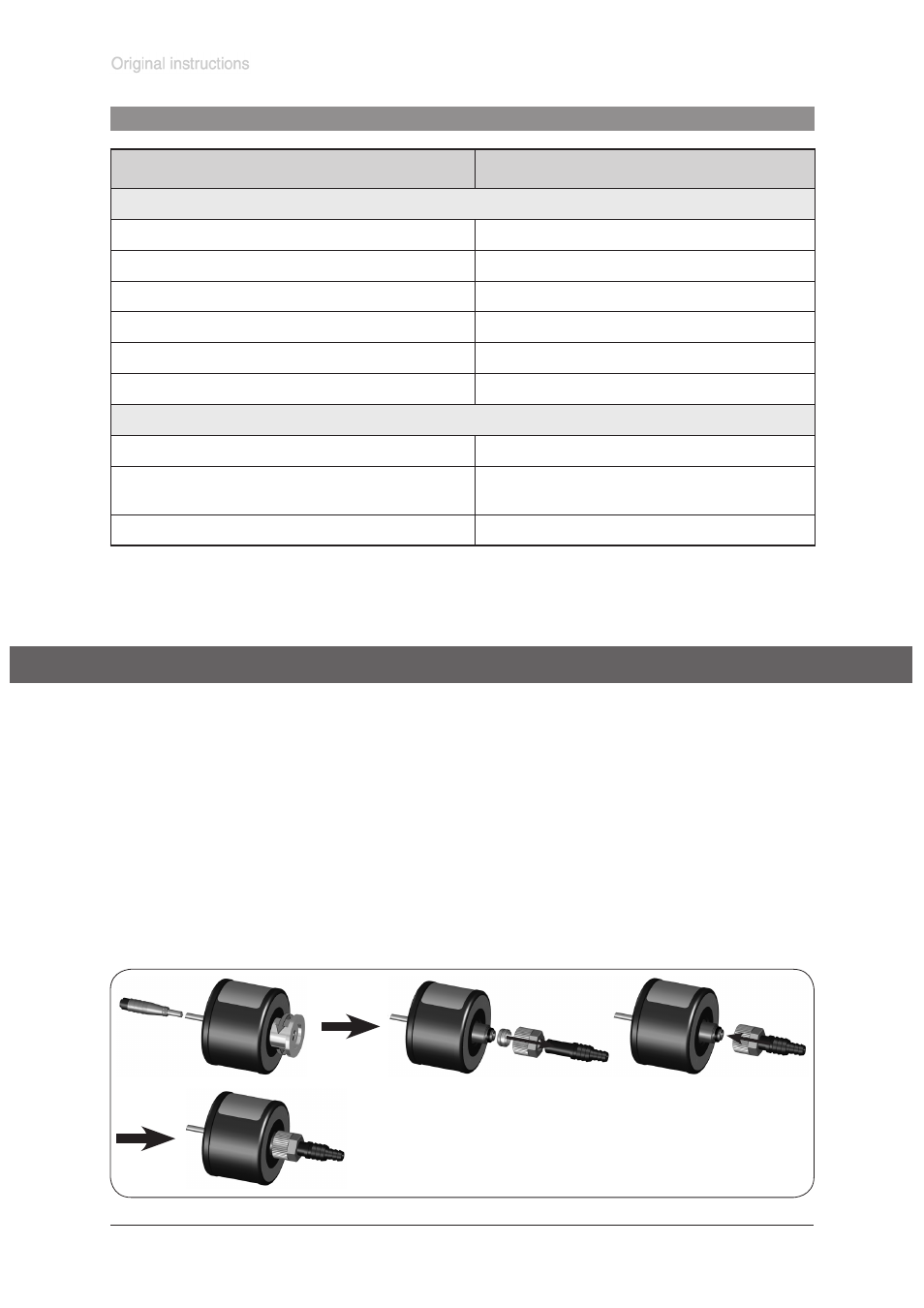

Changing the vacuum connector

Installing the hose nozzle:

Unscrew the flange (using a 17 mm open-end wrench, if necessary) to expose the compression fitting

(1). Slip the compression nut, and then the ferrule, onto the smooth end of the supplied hose nozzle (2).

Slide the smooth end of the hose nozzle onto the compression fitting on the VSK 3000 gauge head, and

tighten the compression nut firmly finger-tight (3).

(1)

(3)

(2)