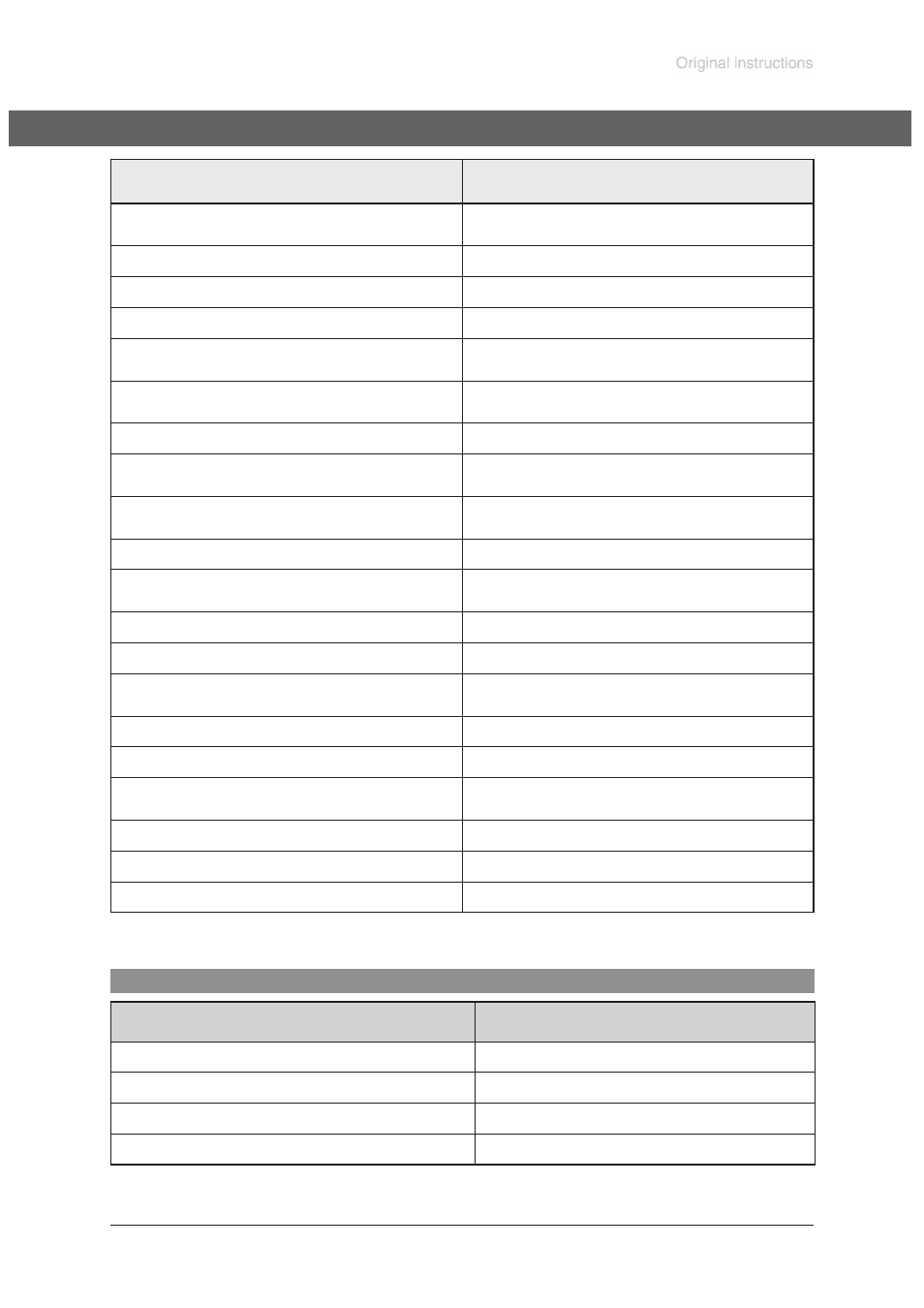

Technical data, Wetted parts – VACUUBRAND DVR 3 User Manual

Page 7

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual: 999072 / 12/01/2011

page 7 of 18

Technische Änderungen vorbehalten!

Type

DVR 3

Measuring principle

capacitive, absolute pressure,

gas type independent

Pressure transducer

ceramic diaphragm (alumina)

Pressure reading

analogue and digital LCD display

Pressure units

mbar, Torr or hPa (selectable)

Measuring cycle

automatic, once in 3s, once in 1s, three times in

1s (factory-set: automatic)

Automatic sleep mode

operation time: 1-1000 minutes or continuous

operation (”On”), (factory-set: 15 minutes)

Measuring range (absolute)

1080 mbar - 1 mbar (810 Torr - 1 Torr)

Maximum permissible pressure at pressure

transducer

1.5 bar absolute

Measurement uncertainty (absolute) after careful

adjustment and at constant temperature

<

±1 mbar (0.75 Torr) /

±1 digit

Temperature coefficient

<

±0.07 mbar/K (0.05 Torr/K)

Maximum permissible temperature of gaseous

media at pressure transducer

continuous operation: 40°C,

for short periods (< 5 minutes): up to 80°C

Ambient temperature range (operation)

10°C to +40°C

Ambient temperature range (storage)

-10°C to +60°C

Permitted relative atmospheric moisture during

operation (no condensation)

30% to 85%

Degree of protection according to IEC 529

IP 40

Ex proof classification

II 2 G Ex ia IIC T4, for use in zone 1

Vacuum connection

small flange KF DN 16 and screw-in hose nozzle

DN 6/10 mm

Power supply

BVE 9V, PTB 98 ATEX 2206, II 2 G Ex ia IIC T5

Weight approx.

430 g

Dimensions L x W x H

116 mm x 116 mm x 66 mm

Technical data

Wetted parts

Components

Wetted materials

Sensor

Aluminium oxide ceramic

Sensor housing

stainless steel

Seals

chemically resistant fluoroelastomer

Vacuum connection / hose nozzle

PBT / PPS glass fibre reinforced