VACUUBRAND PC 2001TE VARIO User Manual

Page 15

page 15 of 50

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. manual-no.: 99 91 35 / 11/04/2008

For condensable vapours (water vapour, solvents, ...):

☞ Do not pump vapour before pump has reached its operating

temperature and with gas ballast valve closed.

☞ Open gas ballast valve. Close gas ballast valve by turning

180°.

☞ The gas ballast valve is open if the flash on the gas ballast

cap shows to the pump.

☞ With gas ballast valve open ultimate vacuum will be reduced,

pumping speed is decreased.

☞ Use inert gas at the air inlet to avoid the formation of explo-

sive mixtures.

In case of low boiling solvents when the formation of conden-

sate is unlikely, the use of gas ballast might be unnecessary.

☞ Operating the pump without gas ballast increases the sol-

vent recovery rates at the exhaust waste vapour condenser.

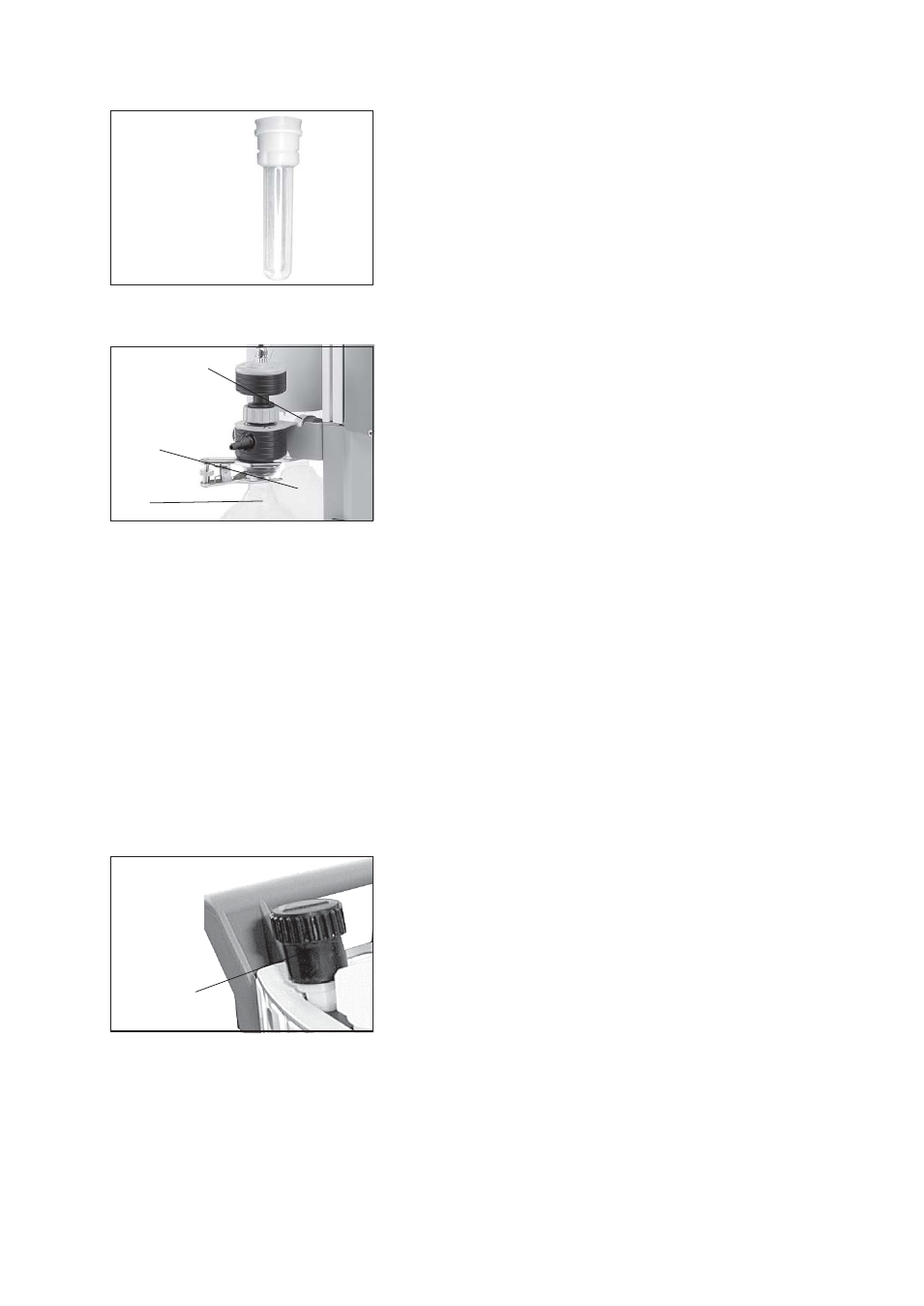

gas ballast

overpressure

safety relief

device

flask at the

outlet

flask at the

inlet

In case of condensation:

Both round bottom flasks are coated with a protective layer to

prevent disintegration in case of breakage or implosion.

➨ Check liquid level in both catchpots during operation. Avoid

overflowing of the catchpots.

☞ Do not overfill the catchpots. Maximum liquid level approx.

80%, to avoid problems when removing the catchpots.

➨ Check liquid level in both catchpots regularely and drain

catchpots in time.

figure condenser

inner part

☞ Separate the condenser inner part from the vacuum installa-

tion to drain the coolant if necessary.

Therefore remove the cap on top of the condesnser. Re-

move the condenser inner part: Turn it and lift. Comply with

regulations when disposing chemicals.

When reassembling check for correct position of the seal

between condenser inner and outer part.

Removing the catchpots:

Catchpot at outlet:

➨ Remove joint clip, remove catchpot and drain condensate.

Catchpot at inlet:

➨ Admit air or inert gas (via inlet of pumping unit) to atmospheric pressure. Remove

joint clip, remove catchpot and drain condensate.

➨ Reassemble drained catchpots.

Important: Comply with regulations when disposing solvents/condensates. Reuse if

possible, purify if contaminated.

Check overpressure safety relief device at the exhaust waste vapour condenser regu-

larly, replace if necessary.

☞ Check especially for conglutination and cracks.