Mbar torr hpa p – VACUUBRAND PC 2001 VARIO User Manual

Page 14

page 14 of 49

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. manual-no.: 999100 / 06/05/2008

For condensable vapours (water vapour, solvents, ...):

☞ Do not pump vapour before pump has reached its operating

temperature and not with gas ballast valve closed.

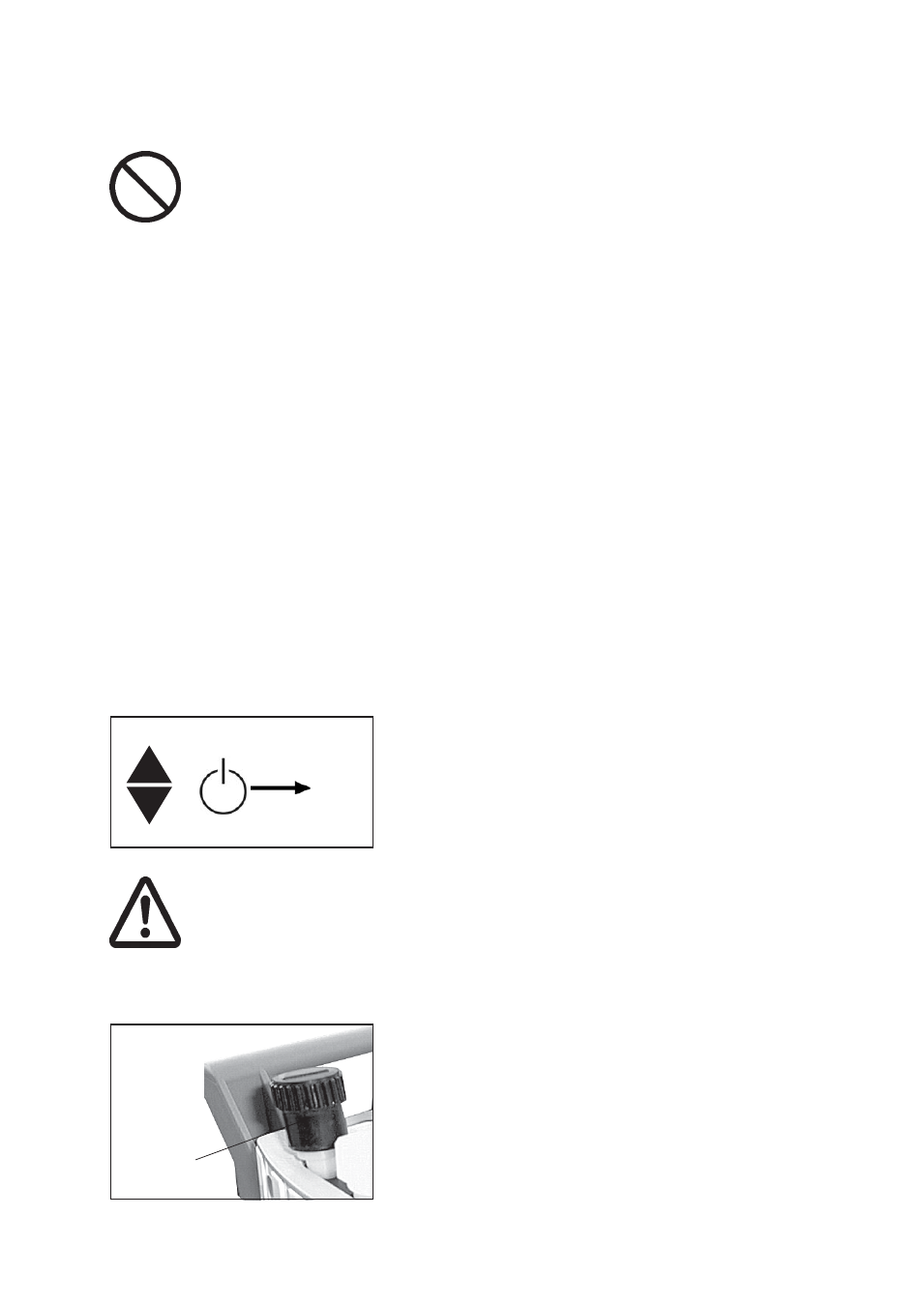

☞ Open gas ballast valve. Close gas ballast valve by turning

180°.

☞ The gas ballast valve is open if the arrow on the gas ballast

cap points towards the pump.

☞ With gas ballast valve open ultimate vacuum will be reduced,

pumping speed is decreased.

☞ Use inert gas at the air inlet to avoid the formation of explo-

sive mixtures.

Attention: Important notes regarding the use of gas ballast

☞ Make sure that air/gas inlet through the gas ballast valve never leads to hazardous,

explosive or otherwise dangerous mixtures. If in doubt, use inert gas.

☞ When using air rather than inert gas, risk of significant damage to equipment and/or

facilities, risk of personal injury or even loss of life exists due to the formation of

hazardous and/or explosive mixtures if air and pumped media react inside or at the

outlet of the pump.

gas ballast

+

mbar

Torr

hPa

p

How to change the pressure units

Press key p

▲ or p▼ during switching on.

☞ The pressure units are displayed, the pressure unit as from

last operation is flashing.

➨ Press key p▲ or p▼ to change pressure unit. Press key

stop when controller displays the desired pressure unit to

finish the operation mode.

☞ Setting of interface parameters, see section “Interface“.

☞ Preselections at the controller, see section “Modes“.

☞ Use and operation of the controller see section “How to operate the controller”.

During operation:

Do not start or operate the pump if pressure at the outlet is higher than 1.1 bar

absolute. Attempts to start or operate the pump at higher pressure may cause block-

ade and damage of the motor.

☞ Comply with max. permitted pressure at the outlet and max. permitted pressure

difference between inlet and outlet.

The pump achieves its pumping speed, ultimate total vacuum and vapour pump-

ing rate only at operating temperature (after approx. 15 minutes).

☞ Prevent internal condensation, transfer of liquids or dust. The diaphragm and valves

will be damaged, if liquids are pumped in significant amounts.

☞ Operate the pump with gas ballast valve open to reduce the condensation of pumped

media (water vapour, solvents, ....) inside the pump.

The motor is protected by a temperature sensor at the circuit board: Current limita-

tion if the temperature at the circuit board is higher than 70°C, switching off the pump

if the temperature is higher than 85°C. In case of blockade of the motor (after 10

attempts to start-up) the pump is switched off.

☞ If the pump is switched off due to safety measures, manual reset is necessary.

Isolate the pump from mains. Eliminate cause of failure before restarting the pump.

☞ Avoid high heat supply (e. g. due to hot process gases).

☞ Ensure sufficient air admittance if pump is installed in a housing.

Settings at the controller