VACUUBRAND MZ 2C +AK+M+D User Manual

Page 13

page 13 of 26

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 999058 / 05/10/2009

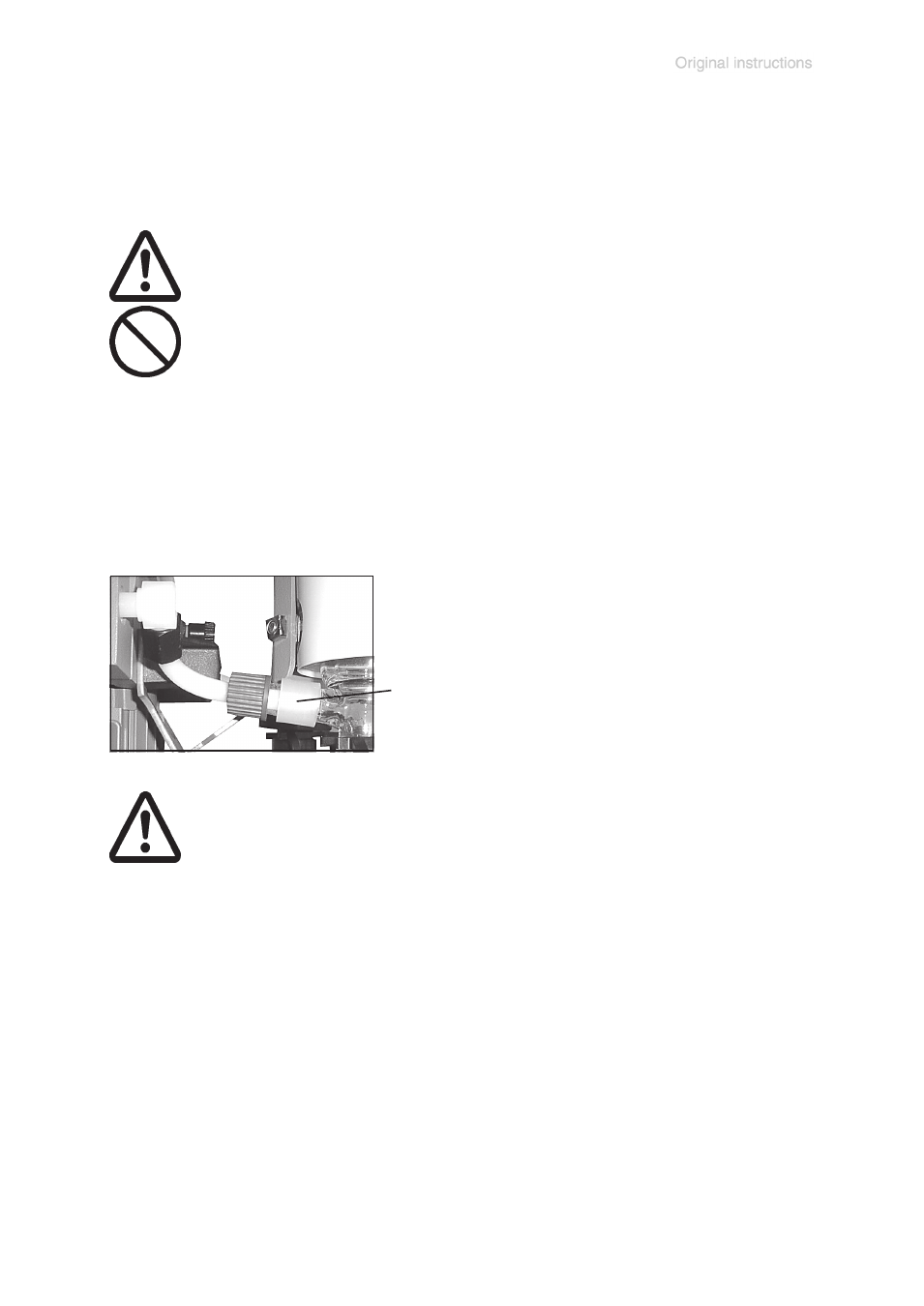

Check overpressure safety relief device at the exhaust waste

vapour condenser regularly, replace if necessary.

☞ Check especially for conglutination and cracks.

overpressure safety relief device

In case of low boiling solvents when the formation of condensate is unlikely, the use of

gas ballast might be unnecessary.

☞ Operating the pump without gas ballast increases the solvent recovery rates at the

exhaust waste vapour condenser.

In case of condensation:

➨ Check liquid level in both catchpots during operation. Avoid overflowing of the catch-

pots.

☞ Do not overfill the catchpots. Maximum liquid level approx. 80%, to avoid problems

when removing the catchpots.

➨ Check liquid level in both catchpots regularely and drain catchpots in time.

Removing the catchpots:

Catchpot at outlet:

➨ Remove joint clip, remove catchpot and drain condensate.

Catchpot at inlet:

➨ Admit air or inert gas (via inlet of pumping unit) to atmospheric pressure. Remove

joint clip, remove catchpot and drain condensate.

➨ Reassemble drained catchpots.

Important: Comply with regulations when disposing solvents/condensates. Reuse if

possible, purify if contaminated.

Attention: Notes concerning the operation of the exhaust waste vapour condenser

➨ Check hose connections prior to starting operation of the cooling system.

➨ Check coolant hoses regularly during operation.

☞ Ensure that the coolant outlet pipeline is always free and that it cannot get blocked.

☞ Maximum permissible coolant pressure at the exhaust waste vapour condenser:

6 bar (absolute)

☞ Comply with the maximum permissible coolant pressures of additional components

in the coolant circuit (e.g coolant valve).

☞ Avoid overpressure in the coolant circuit (e.g. caused by blocked or squeezed cool-

ant hoses).

☞ Permissible range of coolant temperature at the exhaust waste vapour condenser:

-15°C to +20°C

☞ The gas outlet (hose nozzle 10 mm) must not be blocked. The exhaust pipeline has

always to be free and pressureless to enable an unhindered discharge of gases.

☞ Connect the exhaust to a suitable treatment plant to prevent the discharge of dan-

gerous gases and vapours to the surrounding atmosphere.