Traxxas 6809L User Manual

Page 23

SLASH 4X4 ULTIMATE • 23

the right side, R on the left side) to provide 1° of toe-in.

Slash 4x4 Ultimate also includes the plastic rear stub axle carriers as

used on the standard Slash 4X4 Ultimate, which offer 2.5° of toe-in.

They can be installed on either side of the truck, as they are not left/

right specific.

In general, increasing toe-in improves stability, while reducing toe-in

may help “loosen up” the truck’s handling to improve corner speed,

especially on high-grip tracks. Experiment to see what works best

for your track and driving style.

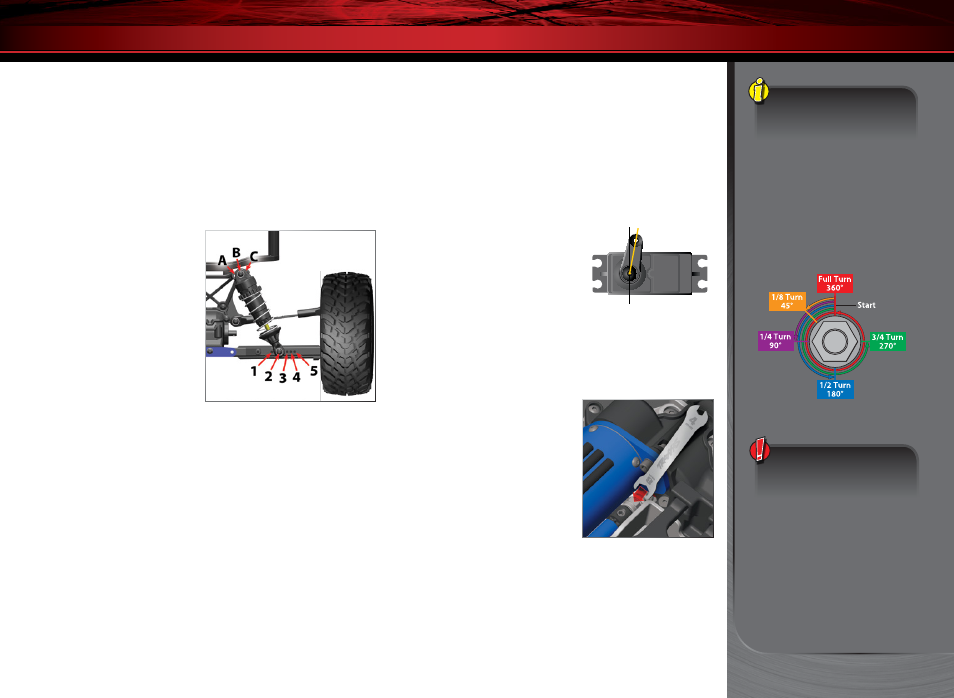

SHOCK MOUNTING POSITIONS

Big bumps and rough terrain

require a softer suspension

with the maximum possible

suspension travel and ride

height. Racing on a prepared

track or on-road use requires

a lower ride height and firmer,

more progressive suspension

settings. The more progressive

suspension settings help

reduce body roll (increased roll

stiffness), dive during braking,

and squat during acceleration.

The suspension of your model has been set up for off-road

performance (position 2 on the front suspension arms and position

3 on the rear suspension arms). If you plan on driving on hard

surfaces the following changes should be made:

1. Move the front shocks to position 3 on the suspension arms.

2. Move the rear shocks to position 4 or 5 on the suspension arms.

3. Reduce the ride height by loosening the upper spring

pre-load spacer.

4. Position 1 is not recommended for front or rear.

CENTERING YOUR SERVO

If you have removed the servo horn from your model’s steering servo,

or the servo has been removed for service or cleaning, the servo must

be re-centered prior to installation of the servo horn or installation of

the servo in the model.

1. Remove the front module from the vehicle to access the

steering servo.

2. Connect the steering servo to channel 1 on the receiver. Connect

the electronic speed control (ESC) to channel 2. The white wire on

the servo lead is positioned towards the receiver’s LED.

3. Turn the transmitter power switch on. Make certain the

transmitter’s batteries are not depleted.

4. Turn the transmitter’s steering trim knob to the center “0” position.

5. Disconnect motor wires “A” and “C” (see page 11) to prevent the

motor from turning during the next steps. Connect a fresh battery

pack to the speed control and turn on the ESC (see page 17). The

servo’s output shaft will automatically jump to its center position.

6. Install the servo horn onto the servo

output shaft. The servo horn should

be aligned one spline clockwise from

perpendicular alignment with the

servo case (not the chassis).

7. Check servo operation by turning

the steering wheel back and forth to

ensure that the mechanism has been centered properly and you

have equal throw in both directions. Use the transmitter’s steering

trim knob to fine-tune the position of the servo horn so the model

tracks straight when the steering wheel is at neutral.

ADJUSTING THE SLIPPER CLUTCH

The model is equipped with an

adjustable slipper clutch that is built

into the large spur gear. The purpose

of the slipper clutch is to regulate the

amount of power sent to the wheels

to prevent tire spin. When it slips,

the slipper clutch makes a high-pitch

whining noise. To adjust the slipper,

use the included wrench to hold

the adjusting nut and roll the model

forward to tighten and reverse to

loosen.

Place the model on a high-traction surface, such as carpet . Adjust the

slipper so that you can hear it slip for approximately two feet from a

standing, full throttle start. (Learn more about adjusting the slipper

clutch in the sidebar.)

BASIC TUNING ADJUSTMENTS

To achieve a good starting

point for the slipper clutch

in this model, remove the

slipper gear assembly from

your model (see page 25 for

instructions) and tighten

the slipper clutch adjusting

nut clockwise until the

slipper clutch adjusting

spring fully collapses (do

not over tighten), and then

turn the slipper clutch nut

counterclockwise one full

turn.

Do not run your model with

the slipper clutch adjusting

spring fully compressed. The

minimum recommended

slipper clutch setting is 1/2

turn counterclockwise from

fully compressed.