Traxxas 6907 User Manual

Page 19

TRAXXAS • 19

# Spur Gear Teeth

= Final Gear Ratio

# Pinion Gear Teeth

Gearing Compatibility Chart:

The chart below shows

recommended gear combination

ranges for your model.

Spur Gear

Pinion Gear

62

65

68

13

-

-

-

14

-

-

4.86

15

-

-

4.53

16

-

-

4.25

17

-

3.82

4.00

18

-

3.61

3.78

19

-

3.52

3.58

20

3.10

3.25

3.40

21

2.95

3.10

3.24

22

2.82

2.95

3.09

23

2.70

2.83

2.96

Stock out-of-box setup,

recommended for most running

Usable gearing range

Fits, but not recommended

GEARING AND DIFFERENTIAL

Changing the gearing allows you to fine tune the speed of the

model and control the temperatures of the battery packs and

motor. Use a lower gear ratio (numerically larger) to reduce current

draw and temperatures. Use a higher gear (numerically lower)

to increase top speed. Use the following formula to calculate the

overall ratio for combinations not listed on the gear chart:

When using “higher” gear rations (numerically lower), it is important

to monitor the temperatures of the battery and motor. If the battery

is extremely hot (150°F), and/or the motor is too hot to touch

(200°F), your model is probably over-geared and drawing too much

current. This temperature test assumes that the model is close to

factory stock weight and operates freely with no excessive friction,

dragging, or binding, and the battery is fully charged and in good

condition. Note: Check and adjust gear mesh if a spur and/or pinion

gear is changed.

This model is equipped with a Traxxas ET 2400 motor. The gear

combination that comes stock on each model provides good overall

acceleration and top speed.

Repetitive starting and stopping will result in motor overheating.

The speed control’s thermal overload protection system will

shut down power in the event of severe overheating. The model

will operate normally once the speed control reaches safe

operating temperature. To prevent motor overheating, only use

recommended gearing.

Changing the Pinion Gear

Follow these steps to alter the gearing of your model. The required

tools are included with your model. Refer to the exploded views in

the included Service and Support Guide for reference:

1. Remove the right rear wheel using the 7mm socket on

the 4-way wrench.

2. Remove the screw holding the pinion cover with

a 2.0mm “L” wrench.

3. Loosen the setscrew that secures the pinion with a 1.5mm “L”

wrench. It does not have to be removed completely.

4. Remove the existing pinion gear from the motor shaft.

5. Using the 2.5mm “L” wrench, loosen the two screws that secure

the motor. You do not need to remove the screws completely.

6. Slide the new pinion onto the motor shaft. If installing a larger

pinion, you will need to slide the motor back in its mount for spur

gear clearance.

7. Align the pinion’s set screw with the flat side of the motor’s shaft,

and align the pinion with the spur gear. Tighten the set screw.

8. Adjust the gear mesh so there is just a “tick” of free play between

the pinion and spur gear.

9. Tighten the motor mounting screws and re-install the pinion cover.

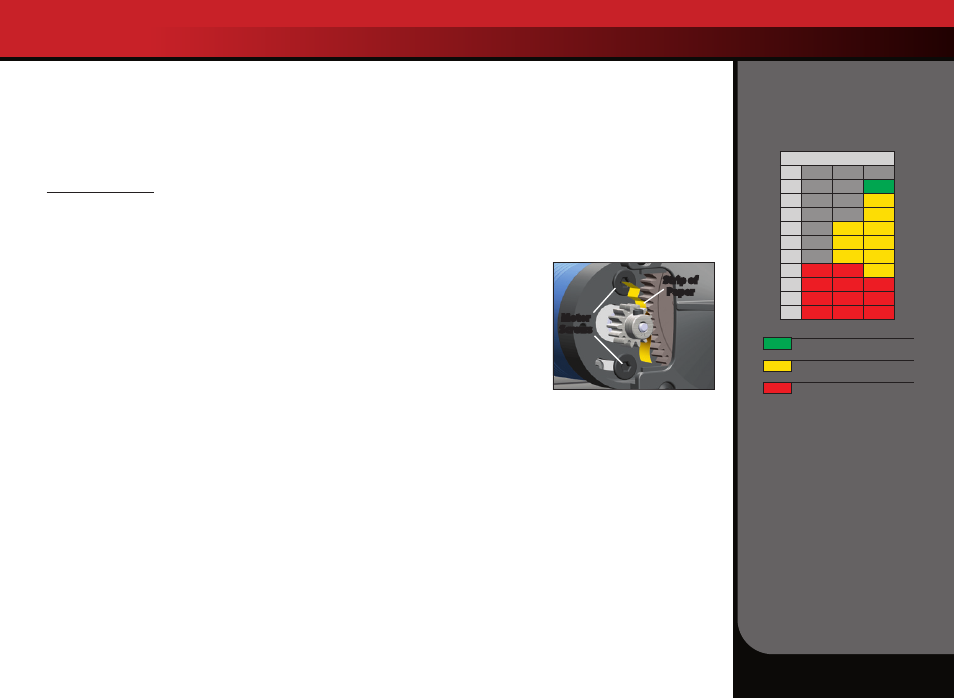

Adjusting Gear Mesh

Incorrect gear mesh is the most

common cause of stripped spur

gears. Gear mesh should be

checked and adjusted anytime

a gear is replaced. To set the

gear mesh, cut a narrow strip

of notebook paper and run it

into the gear mesh. Loosen

the motor screws and slide

the motor and pinion gear into the spur gear. Retighten the motor

screws and then remove the strip of paper. You should be able to

run a fresh strip of paper through the gears without binding them.

Tuning the Differential

The action of the model’s rear gear differential can be tuned for

different driving conditions and performance requirements. From

the factory, the differential is sealed to maintain consistent long-term

performance. Changing the oil in the differential with either lower

or higher viscosity oil will vary the performance characteristics of

the differential. Changing to a higher viscosity oil in the differential

will reduce the tendency for motor power to be transferred to the

wheel with the least traction. Higher viscosity (thicker) oil causes the

differential to act like a limited-slip differential, distributing more

equal power to the left and right wheels. Your model will generally

benefit from higher viscosity oil when being driven on low traction

surfaces. From the factory, the differential is filled with SAE 500K

viscosity silicone oil. The differential must be removed from the

TUNING ADJUSTMENTS

Motor

Screws

Strip of

Paper