Vii system piping warning – Crown Boiler KSZ175 User Manual

Page 14

12

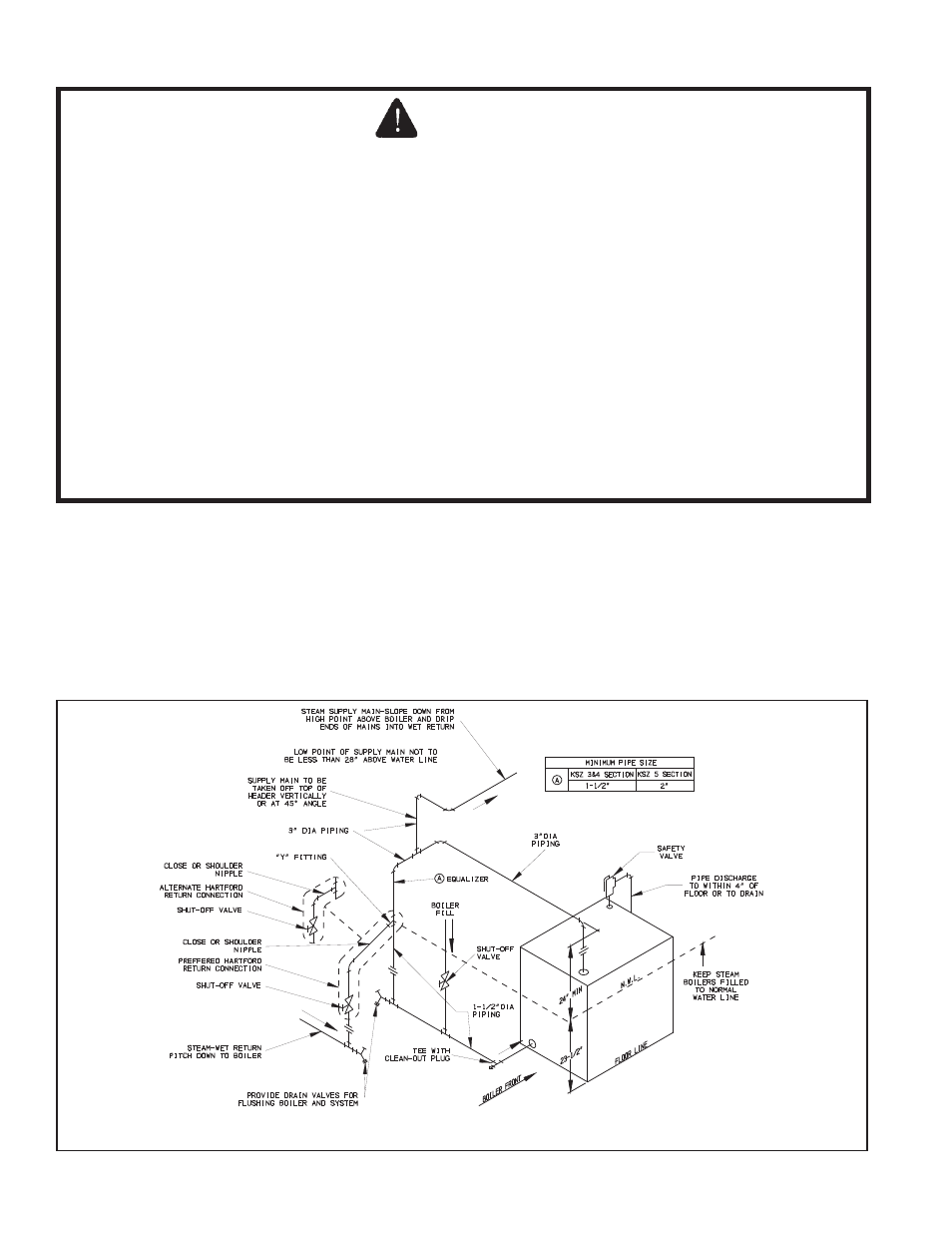

FIGurE 10: StEaM BOIlEr PIPInG FOr GraVItY rEturn

Figure 10 shows recommended near boiler Piping for most common types of gravity return steam systems. Additional

information on steam system design may be found in the I=B=R Guide RHH published by the Air-Conditioning, Heating and

Refrigeration Institute (AHRI).

One of the primary purposes of this near boiler piping is to separate tiny water droplets from the steam exiting the boiler

so that “dry” steam is sent to the system. If the near boiler piping is not correct, wet steam will enter the system and the

following problems may occur:

•

Short cycling on low water

VII System Piping

WARNING

• INSTALL BOILER SO THAT THE ELECTRICAL COMPONENTS ARE PROTECTED

FROM WATER (DRIPPING, SPRAYING, RAIN, ETC.) DURING APPLIANCE

OPERATION AND SERVICE (CIRCULATOR REPLACEMENT, ETC.).

• OPERATION OF THIS BOILER IN A SYSTEM HAVING SIGNIFICANT AMOUNTS OF

DISSOLVED OXYGEN CAN CAUSE SEVERE HEAT EXCHANGER CORROSION

DAMAGE.

• DO NOT USE TOXIC ADDITIVES IN THIS SYSTEM.

• PIPE SAFETY VALVE DISCHARGE TO A SAFE LOCATION. THE SAFETY VALVE

MAY DISCHARGE STEAM OR SCALDING HOT WATER.

• DO NOT INSTALL A VALVE IN THE SAFETY VALVE DISCHARGE LINE.

• DO NOT MOVE SAFETY VALVE FROM FACTORY LOCATION.

• DO NOT PLUG SAFETY VALVE DISCHARGE. BLOCKING THE SAFETY VALVE

MAY RESULT IN BOILER EXPLOSION.