Troubleshooting (continued) – Harbor Freight Tools PAINT SPRAY GUN 30224 User Manual

Page 15

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

SKU 30224

Page 15

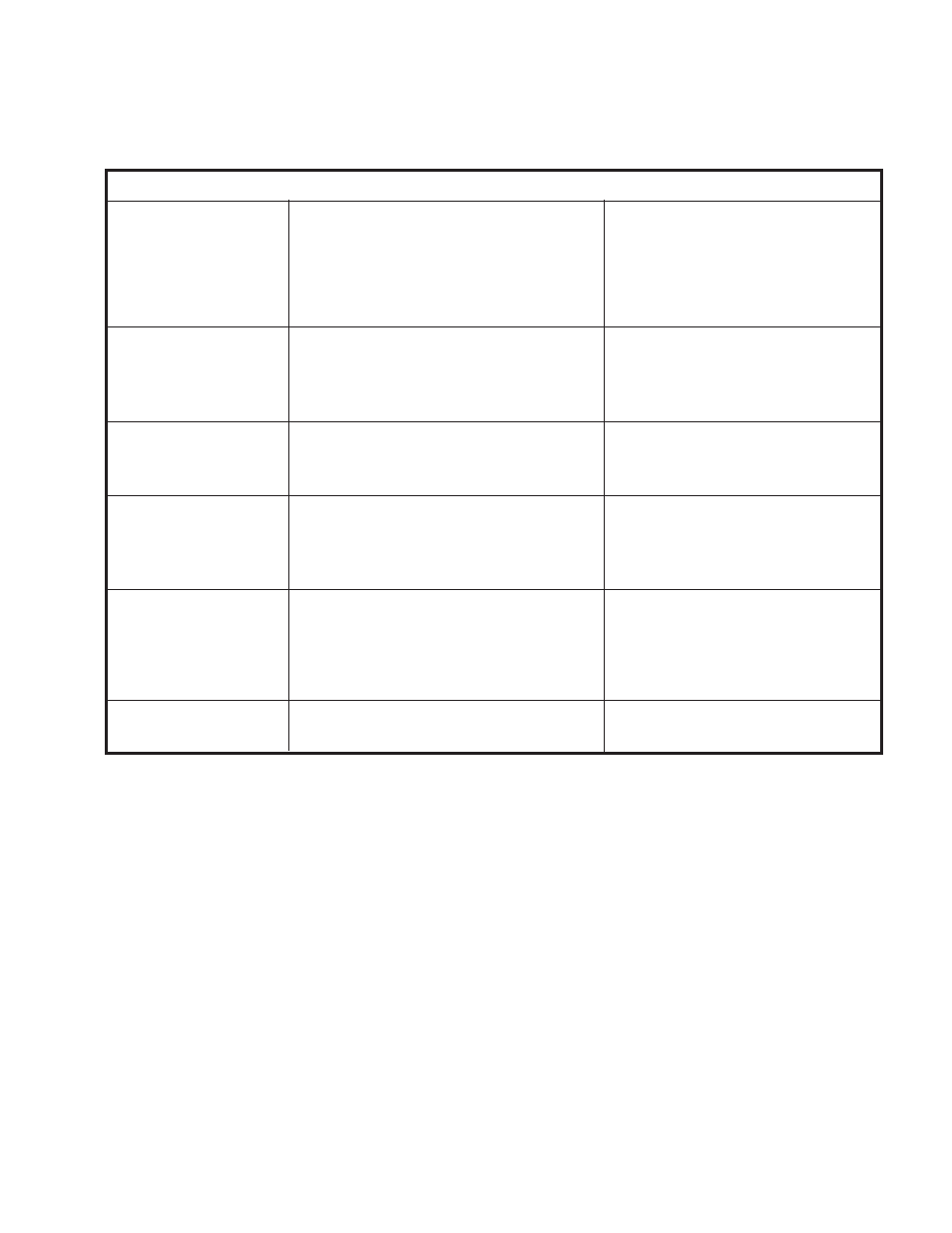

Troubleshooting (continued)

1. Low material level

2. Cup tipped too far

3. Clogged Air Vent

4. Loose fluid inlet connections

5. Dry or loose fluid needle Packing Nut

6. Loose/damaged fluid tip/seat

1. No pressure at gun

2. Fluid control not open enough

3. Fluid too thick

1. Improper application speed

2. Improper distance from workpiece

3. Too much pressure

1. Dirty tip

2. Tight Packing Nut

3. Broken fluid needle spring

4. Worn or damaged tip

1. Dirty air valve/seat

2. Sticking air valve

3. Damaged air valve spring

4. Worn/damaged air valve/seat

5. Bent valve stem

1. Packing Nut loose

2. Packing worn or dry

Sputtering Spray

Will Not Spray

Overspray

Fluid Tip Leakage

Air Leaking from

Air Cap

Fluid Leaking from

Packing Nut

1. Refill

2. Hold upright

3. Clean vent hole

4. Tighten

5. Lubricate and/or tighten

6. Adjust or replace

1. Check air hoses

2. Open fluid control

3. Thin fluid or increase pressure

(within Maximum range)

1. Move moderately and parallel

2. Adjust distance

3. Reduce air pressure

1. Clean

2. Loosen Packing Nut

3. Replace

4. Replace tip and/or needle

1. Clean

2. Lubricate

3. Replace

4. Replace

5. Replace

1. Tighten without restricting

2. Replace or lubricate (non-silicone)

Problem

Cause

Solution