Solberg Replacement Filter Elements User Manual

Page 3

Solberg Manufacturing, Inc., 1151 Ardmore Itasca, IL 60143 USA

Page 3

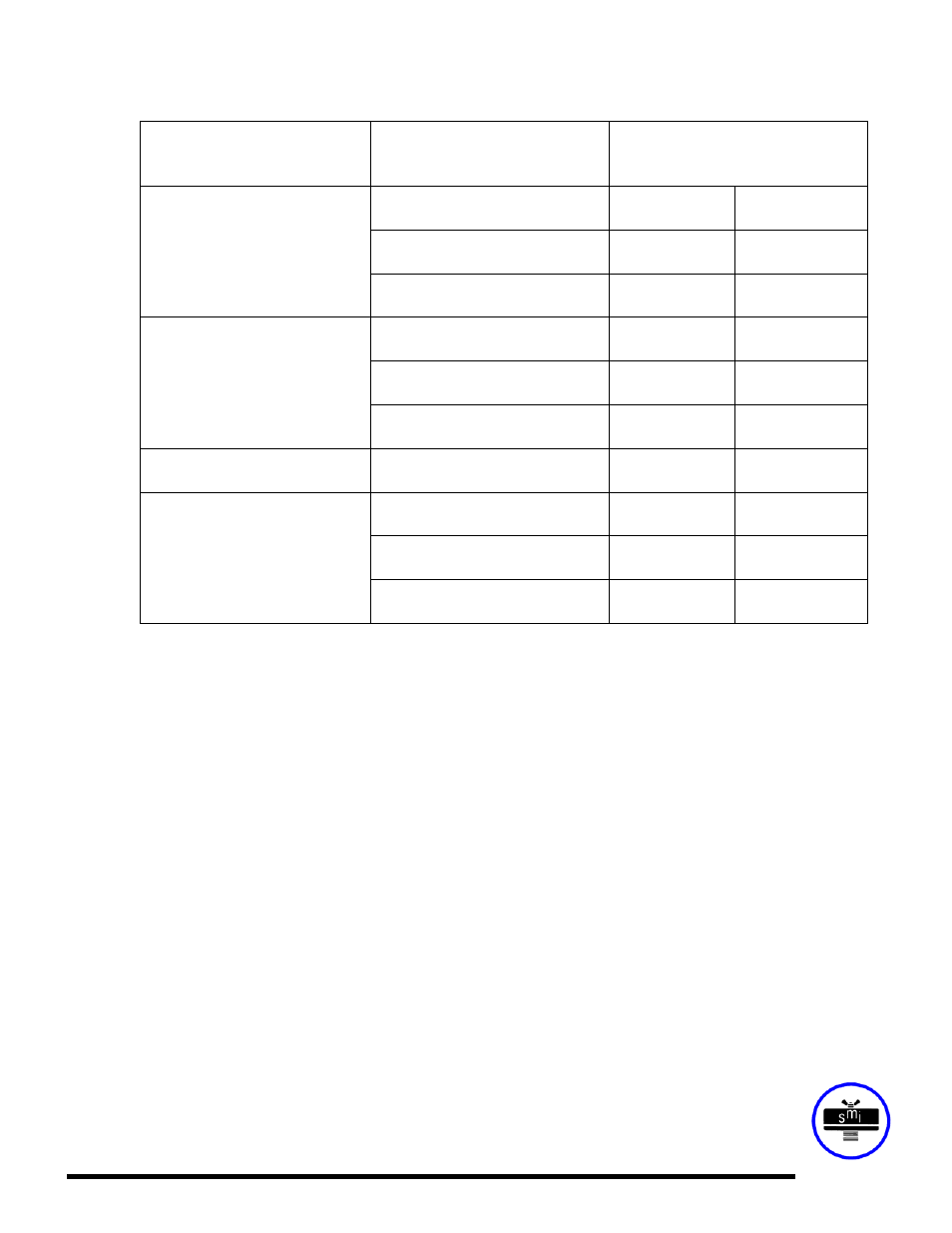

Filtration Efficiency

Requirements

(99+% efficiency)

Environmental Conditions

Air to Media Ratio

Industrial Duty (clean,

office/warehouse-like)

30 CFM

/

ft

2

(51m

3

/h)

/

cm

2

Severe Duty (workshop,

factory-like)

15 CFM

/

ft

2

(25.5m

3

/h)

/

cm

2

Industrial Grade 2-micron

Paper

Extreme Duty (Foundry,

Construction-like)

10 CFM

/

ft

2

(17m

3

/h)

/

cm

2

Industrial Duty (clean,

office/warehouse-like)

50 CFM

/

ft

2

(85m

3

/h)

/

cm

2

Severe Duty (workshop,

factory-like)

40 CFM

/

ft

2

(68m

3

/h)

/

cm

2

Industrial Grade 5-micron

Polyester

Extreme Duty (Foundry,

Construction-like)

25 CFM

/

ft

2

(42.5m

3

/h)

/

cm

2

Industrial Grade 1-micron

Polyester

Severe Duty (Foundry,

Construction-like)

10 CFM

/

ft

2

(17m

3

/h)

/

cm

2

Industrial Duty (clean

office/warehouse-like)

10 CFM

/

ft

2

(17m

3

/h)

/

cm

2

Severe Duty (workshop,

factory-like)

7 CFM

/

ft

2

(12m

3

/h)

/

cm

2

Industrial Grade 0.3-micron

HEPA Glass @ 99.97%

efficiency

Extreme Duty (Foundry,

Construction-like)

5 CFM

/

ft

2

(8.5m

3

/h)

/

cm

2

Table 2

Rule of Thumb

#

4: Pressure drop is also caused by the dirt holding capacity of

the element. As the element fills up with dirt, the pressure drop increases. It is

important to document the pressure drop across a given filter when it is new and

then clean or replace it when the pressure drop increases by 10” to 15” / 250-

380mm H

2

O from the original reading.

Rule of Thumb #5: The inlet connection greatly influences the overall pressure

drop of the filter system. To minimize the restriction contributed by an inlet filter, a

velocity of 6,000 ft/min (10200m

3

/h) or less is suggested through the outlet pipe.

The table below lists the suggested flows based on pipe size:

Ph: 630.773.1363 Fax: 630.773.0727 Email: [email protected] Web: www.solbergmfg.com

Rev: MMEL-6294

SOLBERG