Carburettor cleanliness, Subsequent readjustments, Parts list – O.S. Engines 2BK Carb - 21283020 User Manual

Page 2

4) Carry out adjustments patiently under actual running conditions,

until the engine responds quickly and positively to the throttle

control.

Note: Mixture adjustments cannot be made accurately under 'no

load' running conditions which, in any case, are not advised

since such running carries a risk of damaging the engine

through over-reving.

5) With the optimum mixture control screw position, light smoke is

visible during high speed running, and the engine revolutions in-

crease smoothly during acceleration.

Remember that, if the engine is operated with the fuel/air mix-

ture slightly too lean, it will overheat and run unevenly. As with

all engines, it is advisable to set both needle-valve and mixture

control screw very slightly on the rich side of the best rpm

setting, as a safety measure.

6) If the engine runs too fast with the throttle closed, the throttle

stop screw should be turned counter-clockwise to allow the

throttle opening to be reduced.

Note: In the course of making adjustments, it is just possible that

the mixture control screw may be inadvertently screwed in or

out too far and its original position lost. In this case, reset

the controls as follows:

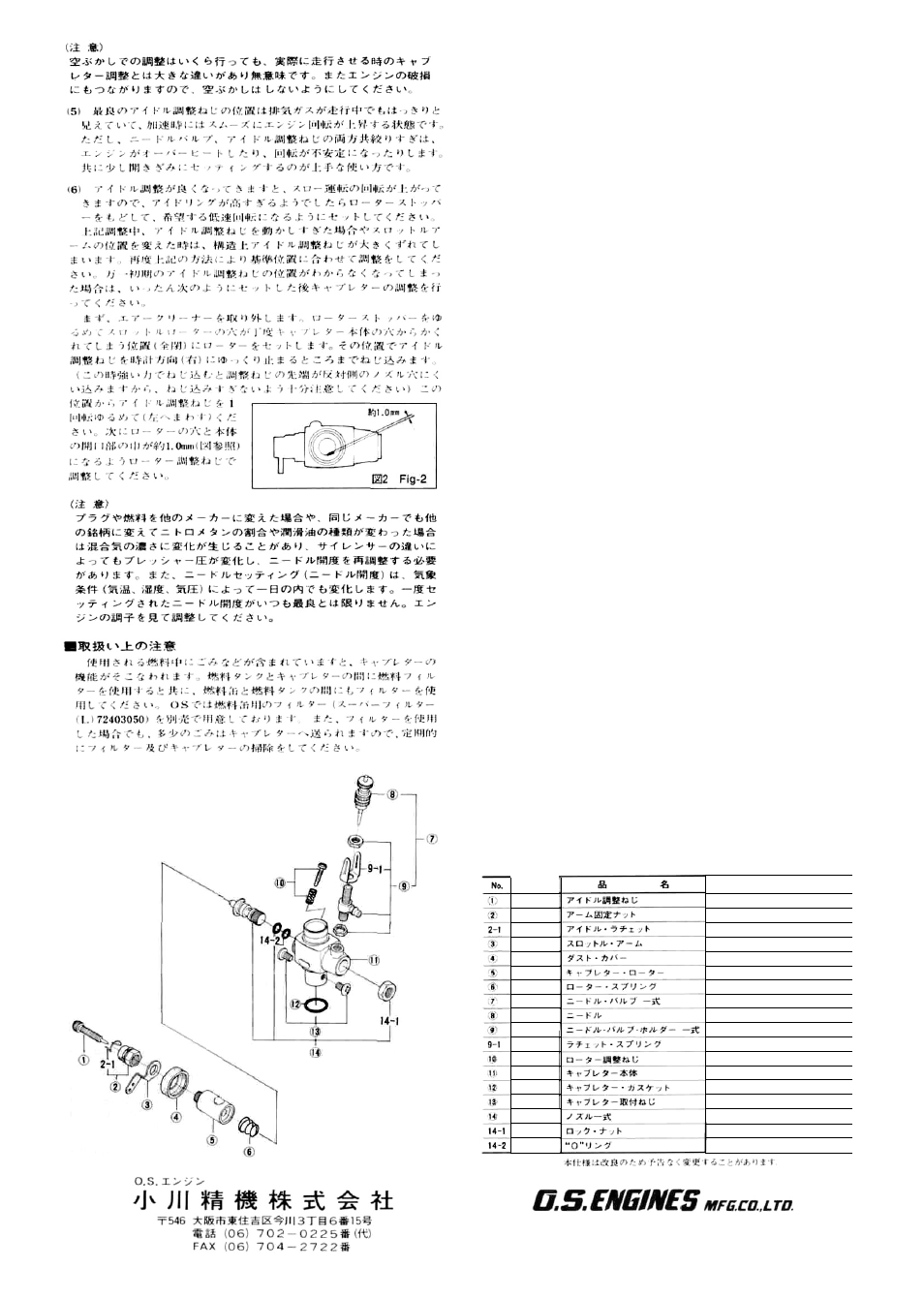

First, remove the air cleaner. Then, unscrew the throttle stop

screw until the throttle opening is just closed completely. At

this point, screw in the mixture control screw slowly clock-

wise until it stops. (Do not use force, otherwise the screw tip

will damage the jet hole on the opposite side.) Now unscrew

the mixture control screw one complete turn. Finally, turn

the throttle stop screw slowly clockwise until the throttle

rotor is opened just 1.0mm as shown in Fig. 2 and fix this

setting by tightening the lockout.

CARBURETTOR CLEANLINESS

The correct functioning of the carburettor depends on its small fuel

orifices remaining clear. The minute particles of foreign matter that

are present in any fuel, can easily partially obstruct these orifices

and upset mixture strength so that engine performance becomes

erratic and unreliable.

O.S. 'Super-Filters' (large and small) are available, as optional extras,

to deal with this problem. One of these filters, fitted to the outlet

tube inside your refueling container, will prevent the entry of

foreign material into the fuel tank. It is also recommended that a

good in-line filter be installed between the tank and carburettor.

Do not forget to clean the filters regularly to remove dirt and lint

that accumulate on the filter screens. Also, clean the carburettor

itself occasionally.

SUBSEQUENT READJUSTMENTS

Once the engine has been run-in (see engine instructions) and the

carburettor controls properly set up, it should be unnecessary to

alter the mixture settings, except to make minor adjustments to

the Needle-Valve occasionally, to take account of variations in

climatic conditions.

The use of a different fuel, however, particularly one containing

more, or less, nitromethane and/or a different type or proportion

of lubricating oil, is likely to call for some readjustment of the

Needle-Valve.

Remember that, as a safety measure, it is advisable to increase the

Needle -Valve opening by an extra half-turn counter-clockwise,

prior to establishing a new setting. The same applies if the silencer

type is changed. A different silencer may alter the exhaust pressure

applied to the fuel feed and call for a revised Needle-Valve setting.

PARTS LIST

Code No.

22481628

22481420

22481449

22681419

21283210

21481200

22481506

21283900

21181976

21283940

21111300

2268)3)0

21283100

22615000

23081706

21283962

2128396)

24881824

Description

Mixture Control Screw

Throttle Lever Fixing Nut

Idle Ratchet

Throttle Lever

Dust Cover

Rotor

Rotor Spring

Needle Valve Assembly

Needle

Needle Valve Holder Assy

Ratchet Spring

Throttle Stop Screw

Carburettor Body

Carburettor Rubber Gasket

Carburettor Fixing Screw

Nozzle Assembly

Locknut

"0" ring

The specifications are subject to alteration for improvement without notice.

6-15 3-chome Imagawa Higashisumiyoshi-ku

Osaka 546,Japan. TEL (06)702-0225

FAX. (06) 704-2722

© Copyright 1987 by OS. Engines Mfg. Co., Ltd. All rights reserved. Printed in Japan

60130010-29607