O.S. Engines 2BK Carb - 21283020 User Manual

O.s. 2bk

O.S. 2BK

OPERATING INSTRUCTIONS FOR THE O.S. TYPE 2BK CARBURETTOR

The O.S. Type 2BK carburettor has been designed for CZ Series 'off-road' racing car engines. Having a larger throat and

incorporating an automatic mixture control device, it releases the full potential of the engine, providing positive throttle

response and rapid acceleration.

Note: It is essential that a muffler pressurized fuel feed system be used. Make sure that the fuel tank cap is closed tightly.

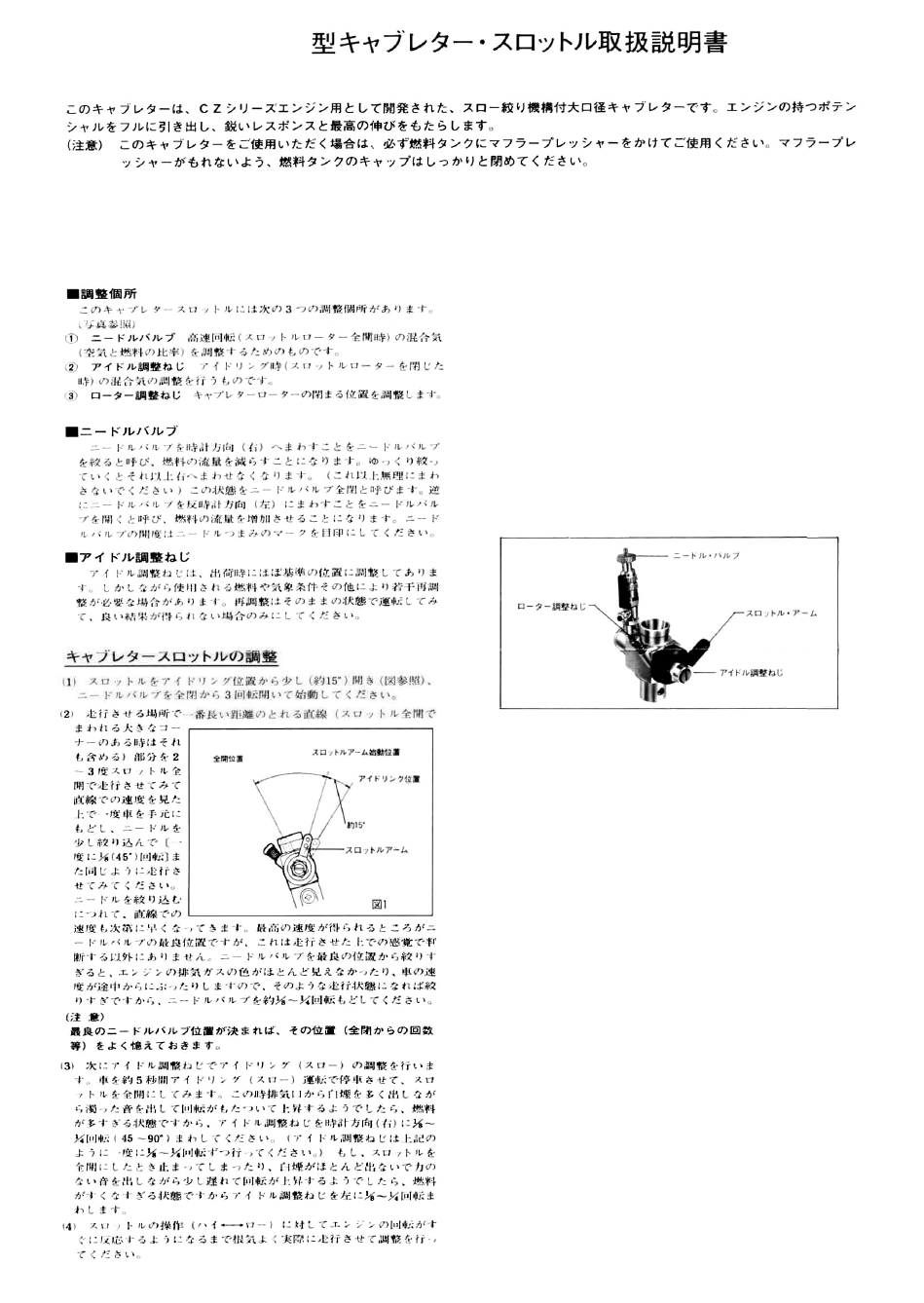

Three adjustable controls are provided on the Type 2BK

carburettor. (See photo below.)

• The Needle-Valve; Fur adjusting the mixture s t r e n g t h when the

throttle is fully open.

• The Mixture Control Screw: For adjusting the mixture strength

at part-throttle and idling speeds, to obtain steady idling and

smooth acceleration to mid speeds.

• The Throttle Stop Screw: For setting the position where the

carburettor rotor is closed.

NEEDLE VALVE

Turn the needle-valve clockwise to close ( f o r leaner mixture). Turn

the needle-valve counter-clockwise to open (for richer mixture).

Turning the needle-valve clockwise reduces the fuel supply to the

engine, while turning it counter-clockwise increases the fuel supply.

Turn the needle-valve clockwise slowly. The position where the

needle-valve stops is the fully closed position. It may be convenient

to remember the position of the mark on the needle knob at this

time.

Throttle Stop

Screw

Throttle Lever

Mixture Control Screw

Needle Valve

MIXTURE CONTROL SCREW

The mixture control screw has been factory set for the approximate

best result. However, different fuels and/or climates may require

minor adjustment. First, run the engine as received, and re-adjust

the mixture control screw only when necessary.

ADJUSTMENT

1) Open the throttle slightly from the idling position, and open the

needle-valve three turns from the fully closed position, then start

the engine. (See Fig. 1.)

2) Run the vehicle with the throttle fully open over the longest

available straight-line course — or around a curve of sufficient

radius to permit full-throttle driving, two to three times. Now

return the model to the starting point, close the needle-valve 1/8

turn (i.e. 45°) and repeat the run, taking note of the improve-

ment in performance.

Continue with further runs, gradually reducing the needle-valve

setting and aiming to achieve the best performance.

If the needle-valve is closed below the optimum setting, the

model will slow down, accompanied by visibly diminished

exhaust smoke, in which case, throttle down, stop the vehicle

and reopen the needle-valve 1/8 — 1/4 turn (i.e. 45° to 90°).

Note: Having established the optimum needle-valve setting, make a

note of the number of turns necessary to re-establish this

from the closed position.

3) After the optimum needle-valve setting has been determined, the

mixture control screw should be checked as follows:

With the engine running, close the throttle and allow it to idle

for about five seconds, then open the throttle fully. If, at this

point, the engine puffs out a good deal of smoke and does not

accelerate smoothly and rapidly, it is probable that the idling

mixture is too rich. In this case, turn the mixture control screw

clockwise 1 / 8 - 1 / 4 turn (45° to 90°).

If, on the other hand, the engine tends to speed up momentarily

and then cut out abruptly when the throttle is opened, the idling

mixture is too lean. In this case, turn the mixture control screw

counter-clockwise 1/8 - 1/4 turn (45° to 90°).

Note; Mixture control screw adjustment should be made in incre-

ments of 1/8 — 1/4 turn (45° to 90°), checking the effect on

the throttle response of each small adjustment.

Fig1

Throttle lever

approx.15

Idling position

Starting position

Fully opened

position