O.S. Engines GT60 User Manual

Page 2

238

2210-12 238-10

248-10

Fuel Inlet

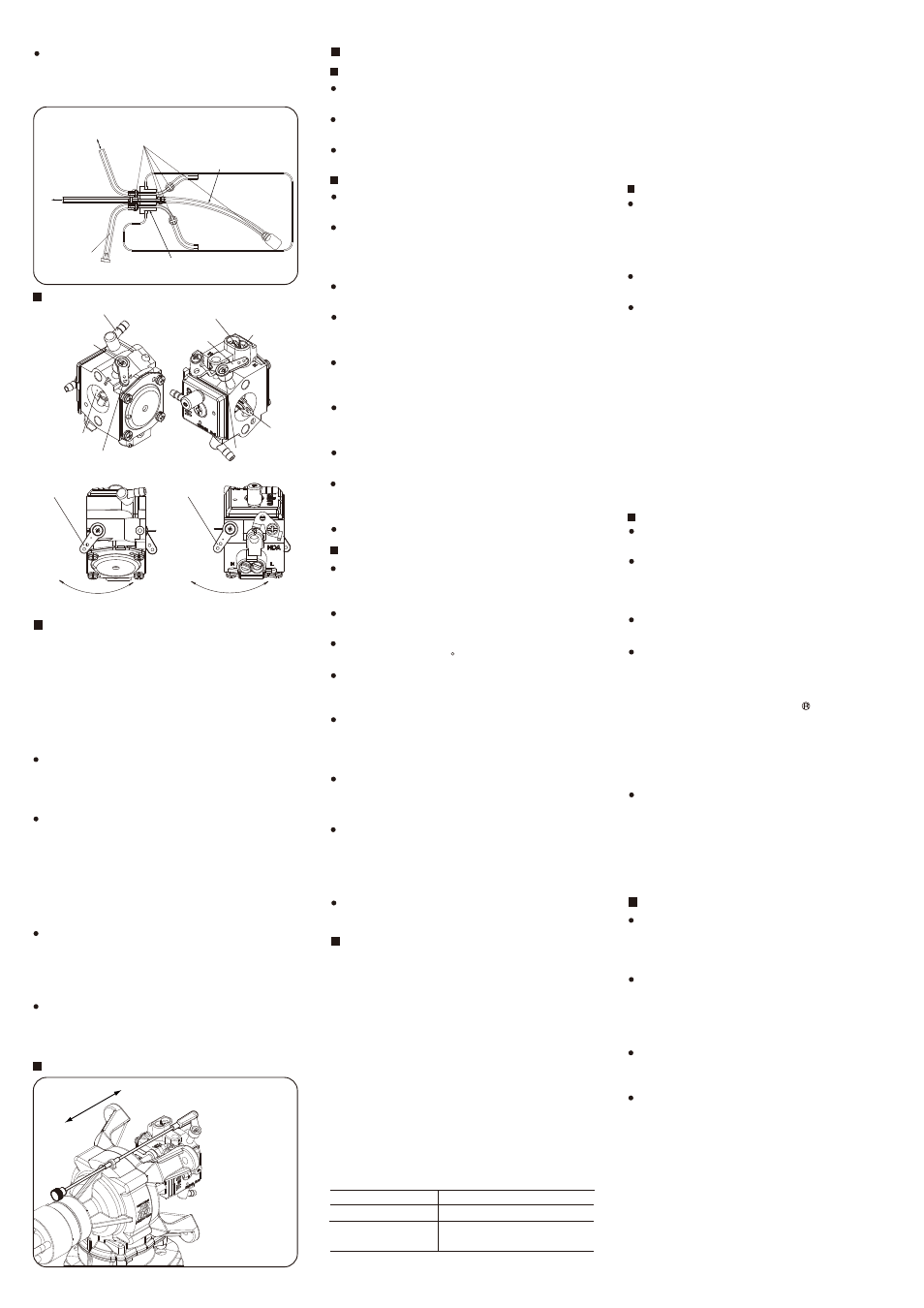

CARBURETOR PARTS NAME

High Speed

Needle

Slow Speed Needle

Throttle Valve Lever

Choke Valve

Lever

Throttle Valve Lever

Retaining Screw

Choke Valve Lever

Retaining Screw

CARBURETOR LINKAGE

NOTE

Before connecting the throttle linkage, make sure

that the throttle valve lever does not interfere with

the bulkhead or mount of the model when it is fully

closed and opened.

In order to obtain suitable idling, connect the throttle

linkage so that the throttle valve lever may be

located at 2 to 3 degrees opened position from fully

closed position when the throttle stick on the

transmitter is fully pulled down, and the throttle valve

may be fully closed when the throttle stick as well as

the rim lever on the transmitter are fully pulled down

or engine cut-off mixing is operated.

Connect the linkage so that the throttle valve is fully

opened when the throttle stick on the transmitter is

fully advanced. (Adjust the movement so that the

pushrod does not bind when the throttle valve is fully

closed and fully opened.)

Connect the linkage so that the servo arm and

pushrod, and throttle valve lever make a right angle

when the throttle stick on the transmitter is placed at

mid position to avoid differential action.

Choke valve rod Linkage

Connect the linkage

as illustrated.

NOTE

Linkage parts are

not supplied.

Consumption current is 600mA/6,000rpm. User a

power source of more than 1000mAh capacity.

The ignition module is set not to operate below

120rpm for safety.

The voltage of power source is 4.8~7.6V (rated).

(Ni-Cd, Ni-MH 4~6 cells, Li-Po, Li-Fe 2 cells)

IGNITION MODULE

Major specifications

Installation

Install the ignition module taking sufficient

anti-vibration measures.

Install the ignition module at least 100mm away

from the engine and in a place where there is airflow

so that engine exhaust heat and radiation heat do

not affect it's operation.

Do not share the power source with receiver and

use a separate power source.

Equip an ON/OFF switch between the ignition

module and its power source and install it in a place

where can be operated from outside the model.

Install the ignition module and its power source as

far as possible away from the servos and receiver

power source.

Connect the sensor leads of the igniter module

(while, red, black three parallel wires) to the sensor

leads from the engine.

Connect the battery leads of the igniter module (red,

black two parallel wires) to the power source.

Make sure the jackets of high tension cord does not

touch the engine and cowl to avoid accidental short

circuit.

Install he plug cap on the plug securely.

Precautions

Do not disassemble the ignition module and plug

cap. (The ignition module is irreparable. Replace it

when necessary.)

Be careful not to mount the ignition module so that it

can be hit by water, gasoline or exhaust.

Avoid using the engine when the external

temperature is over 40 C.

Do not move the rpm sensor as it is placed at it's

optimum position, otherwise the engine will not run

properly.

Do not pull on the high tension cord to remove the

plug cap, or the wire will break. Be sure to hold the

plug cap to remove it. Be careful not to damage

your fingers while removing it.

Do not connect nor disconnect the rpm sensor with

the ignition module on, or there is a possibility it will

fire and the engine start.

Check the ignition module for spark when installing

the plug cap on the plug and be careful about

getting a shock. Make sure there is no flammable

material or gasoline vapors near by that could

ignite.

Do not turn the propeller with the ignition module

on, or there is a possibility the engine will start.

PROPELLER

The choice of propeller depends on the design and

weight of the aircraft and on the type of flying in which

you will be engaged. Determine the best size and type

after practical experimentation. As s starting point,

refer to the props listed in the table shown below.

Slightly larger, or even slightly smaller props than those

shown in the table may be used, but remember that

propeller noise will increase if blade tip velocity is

raised due to high rpm or if a larger diameter/lower

pitch prop is used. Be well aware propeller rotating arc

is very large due to a large propeller used with this

engine. Carry out the needle adjustments only after

stopping the engine. Do not allow your face or hands to

come close to the rotating prop.

Type

Size (DxP)

Running-in

Acro/Scale

Warning:

Make sure that the propeller is well balanced.

An unbalanced propeller and/or spinner can cause

serious vibration which may weaken parts of the

airframe or affect the safety of the radio-control

system. Do not use any propeller which has

become split, cracked or nicked even very slightly,

or received strong impact even if no apparent

damage is visible.

PROPELLER & SPINNER ATTACHMENT

Since the GT60 is intended to be started with an

electric starter, the addition of a spinner assembly for

centering the starter sleeve is desirable. Special

propeller locknut sets are available for use with

spinners. Use a good quality well balanced spinner,

enclosing the propeller boss. Make sure that it is of

precision-made and sturdy construction so that the

spinner shell cannot loosen when the starter is used.

Make sure the spinner notches do not interfere the

propeller. If they do, cut the notches to clear.

MIXING OF OIL

Use regular gasoline. (No need to use high octane

gasoline.)

Alcohol based glow fuel cannot be used in this

engine. Not only will the engine not work properly

but the internal carburetor plastic parts will be

damaged.

Use high quality commercially available 2 stroke

engine oil.

Follow the oil manufacturer’s recommendations

concerning the mixture ratio of gasoline and oil. If

there is no recommendation, mix with a 30:1 ratio.

We have checked and approved the following oil

mixture ratio. KLOTZ ModelLube (50:1), COSMO

Cosmo Terra 2 cycle (50:1), RED LINE Two-Stroke

Racing Oil (40:1). (This does not mean we

guarantee the quality of these oils.)

Follow the instructions in the running-in section

concerning the mixture for running-in.

With a gasoline engine, passages in the carburetor

are narrower than that of a glow engine, and

therefore very sensitive against foreign matter such

as dust. It is suggested to use optional accessory

Super Filter L (Code No. 72403050) when filling a

tank in the model from a container used for

transportation or storing.

When changing the throttle valve lever and choke

valve lever direction, loosen and tighten each

retaining screw placing each lever at mid position.

(If the throttle valve lever retaining screw is

loosened or tightened with the throttle valve fully

opened or closed, excessive force will be applied,

which will results in breaking the lever.)

(ON)

(OFF)

Throttle Valve

Lever

Choke Valve

Lever

Choke

Throttle

Open

Close

(OFF)

(ON)

Choke

Open

Close

Open

Close

Be sure to install an in-line fuel filter between the

tank and carburetor to prevent foreign matter in the

tank from entering the carburetor. Clean the filter

periodically.

Use a wooden or a carbon fiber propeller.

Do not use a nylon propeller.

If the supplied retaining screws are too long due to a

thinner prop hub or too short due to a thicker prop

hub (cannot be screwed into the drive hub by more

than 10mm), Use suitable length strong steel hex

socket head cap screws.

Install the propeller before the first flight of the day

and remove it after the day’s flight.

Make a habit of always checking the tightness of

propeller retaining screws making sure they are free

of, damage or rust before starting the engine.

Replace the propeller periodically (every 50 flights)

even if it looks as ifs nothing is wrong.

Use a fuel with increased oil content and set the

needle a little on the rich side. Too rich a needle

setting may cause misfiring or erratic running due to

fouling of the plug.

Use a 25:1 fuel/oil mixture if the particular brand of

oil states 50:1 mix. Use a 20:1 fuel/oil mixture if the

particular brand of oil states 30:1 mix. Set only the

high speed needle 200 below maximum rpm. The

low speed needle need not be richened.

No need to carry out running-in on a bench nor with

the model fixed. Just fly the model with the above

mentioned fuel and needle setting.

A total of 10 flights (5~6 litters fuel) are required.

Avoid prolonged full throttle running at initial stage,

and gradually extend the full throttle running time.

RUNNING-IN / STARTING

WARNING:

When ground running the engine, avoid dusty or

sandy locations. If dust or grit is drawn into the

engine, this can have a ruinous effect, drastically

shortening engine life in a matter of minutes.

Throttle Valve

Choke Valve

Be sure to use a gasoline

resistant fuel tank cap.

Be sure to equip

air vent pipe.

Be sure to replace tubing

inside periodically.

tubing for

re-fuelling

Be sure to use fuel line keepers of

stainless wire, etc. to prevent tubing

from coming off.

To carburetor

fuel inlet