Care of fuel pump & regulator, Starting – O.S. Engines FS-200S-P User Manual

Page 10

18

NEVER disassemble the fuel pump or pressure regulator.

Their original performance may not be restored after

reassembly.

DO NOT allow foreign matter to enter the fuel system. Dirt

inside the pump or regulator, no matter how small, may

obstruct the flow of fuel and prevent these components

from working properly.

ALWAYS use fuel filters. Keep the fuel tank scrupulously

clean and filter all fuel as it enters the tank (e.g.via an

O.S.'Super-Filter' Code No.72403050) and use a good

quality in-line filter between the tank and pump. Remember

to inspect filter screens at regular intervals and rinse clean

as necessary.

NEVER use gasoline, kerosene, diesel fuel or other

petroleum products for cleaning the pump, regulator or fuel

lines. Silicone-rubber parts will be ruined by these

materials. Use only alcohol (methanol) or glow fuel for

cleansing these items.

CARE OF FUEL PUMP & REGULATOR

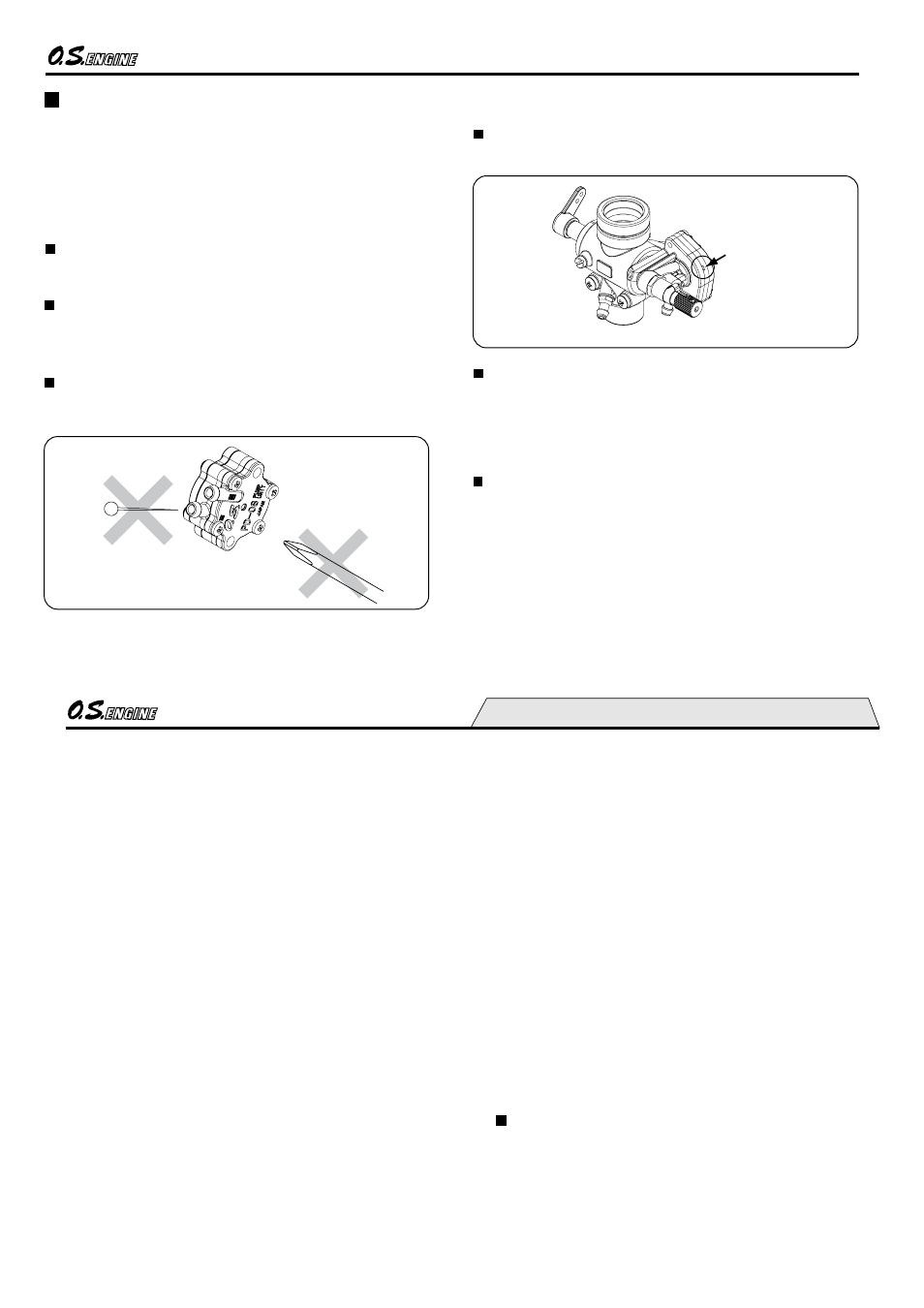

DO NOT obstruct the small rectangular hole at the bottom

of the regulator, nor the regulator will not function correctly.

NEVER insert anything into the inlet or outlet nipples in an

attempt to clear a suspected obstruction. (See CARE &

MAINTENANCE section at the back of this booklet.)

When new, 2~3 minutes of running time will be required

for the pump and regulator to begin functioning properly,

During this period you may not be able to get the full

throttle mixture rich enough. In this case, just run the

engine at approx, 3/4 throttle a little longer.

19

The FS-200S-P is not equipped with manual choke

controls, as it is intended for use with an electric starter

only. A high-torque electric starter not only makes

starting the engine easier, it dispenses with the need for

a choke valve by turning the engine over fast enough to

prime the cylinder.

Starting procedure is as follows:

Check that the current to the glowplug is switched off.

Check that the polarity of the starter battery leads rotates the

engine counter-clockwise when viewed from the front.

Open the needle-valve 2.5-3 turns from the fully closed

position and set the throttle in the fully open position.

Apply the starter and press the starter switch for 5-6

seconds, or until fuel is seen to emerge from the exhaust

outlet, indicating that the cylinder is now primed.

Energize the glowplug and apply the starter. If the starter

fails to rotate the engine completely, this may be due to the

cylinder being over-primed, or to the starter battery being

insufficiently charged.

1.

2.

3.

4.

5.

6.

Check these conditions and, instead of pressing the starter

button after applying the starter, have the starter spinning

before applying it to the engine, to give it a "running start".

When the engine starts, slowly open the throttle, leaving

the needle-valve at its rich starting setting to promote cool

running conditions.

However, if the engine slows down because the mixture is

excessively rich, the needle-valve may be closed a little to

speed it up until it runs evenly.

Now disconnect current to the glowplug and gradually

close the needle-valve so that the rpm increases. Make

adjustments to the needle in small steps.

Abrupt changes at this stage are likely to cause the engine

to stall. Restart the engine by simply applying the starter

with the glowplug re-energized and the throttle at its

starting setting.

7.

8.

Close the throttle-arm to within 15-20

° of the fully closed

position and slowly turn the prop "backwards" (clockwise)

by hand approximately 1.5 turns until it is arrested by

compression.This is to enable the kinetic energy of the prop

to subsequently assist the starter through the compression

stroke to start the engine.

STARTING

Note:

Make sure that the throttle linkage is made so that the

throttle is fully closed when the throttle lever as well as

trim lever on the transmitter are fully pulled down.

How to stop the engine

Pull down the throttle lever and trim lever on the transmitter

fully.