Valve adjusting – O.S. Engines FS-26S-CX User Manual

Page 18

Note:

Valve clearances of all O.S. four-stroke-

cycle engines must be checked and reset

ONLY WHEN THE ENGINE IS COLD.

Procedure is as follows.

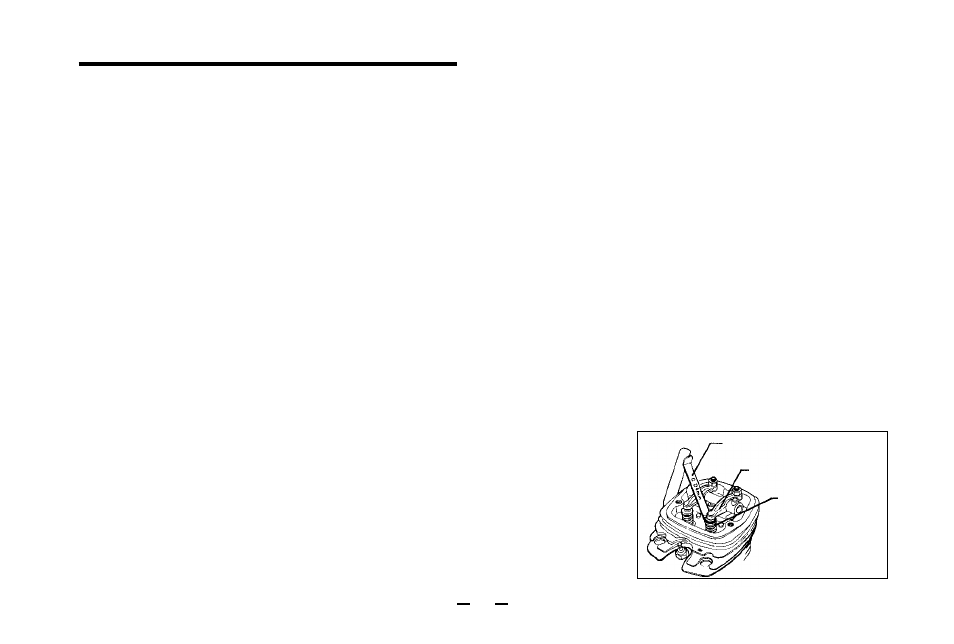

Remove the cover from the rocker-box on

top of the cylinder-head, using the correct

size Allen hex key.

1.

(

1

)

Turn the flywheel counter-clockwise until

compression is first felt, then turn it a further

quarter revolution. At this point, both valves

should be closed. (If the prop driver ('drive

hub') of your engine is engraved with a letter

'T', this mark should now be at the top.)

2.

The standard valve clearance, on both inlet

and exhaust valves, is between 0.04mm and

0.10mm(0.0015-0.004 inch), measured

between valve stem and rocker arm. Use the

0.04mm and 0.10mm feeler gauges to check

clearances.

(See Fig.1.)

3.

Fig.1

0.04mm Feeler Gauge

Rocker Arm

Valve

• Feeler gauge 0.04mm

ALL O.S. four-stroke engines have their

valve(tappet) clearances correctly set before

they leave the factory. However, if, after many

hours of running time have been logged, a loss

of power is detected, or if the engine has to be

disassembled or repaired as a result of an

accident, valve clearances should be checked

and readjusted, as necessary. O.S. Valve

Adjusting Tool Kit is available as optional

accessory.

VALVE ADJUSTING

The kit comes in a plastic case and includes:

(Code No.72200060)

• Feeler gauge 0.1mm

• Hex. key 1.5mm

• Wrench 5mm

• Screwdriver

17