Propeller, Mixture controls, Starting – O.S. Engines 160FX Ring User Manual

Page 10

15

✕

12

~

14, 16

✕

10

~

14,

16.5

✕

10

~

13

17

✕

10

~

13, 18

✕

10

~

12

PROPELLER

The suitability of the prop depends on the size and weight of

the model and type of flying. Determine the best size and type

after the engine has been run in. Check the balance of the

propeller before installing on the engine. Unbalanced

propellers cause vibration and loss of power. Wooden

propellers are to be preferred. Some nylon propellers are not

strong enough to withstand the high power output of these

engines and a thrown blade can be very dangerous.

MIXTURE CONTROLS

Never touch, or allow any object to come into

contact with, the rotating propeller and do not

crouch over the engine when it is running.

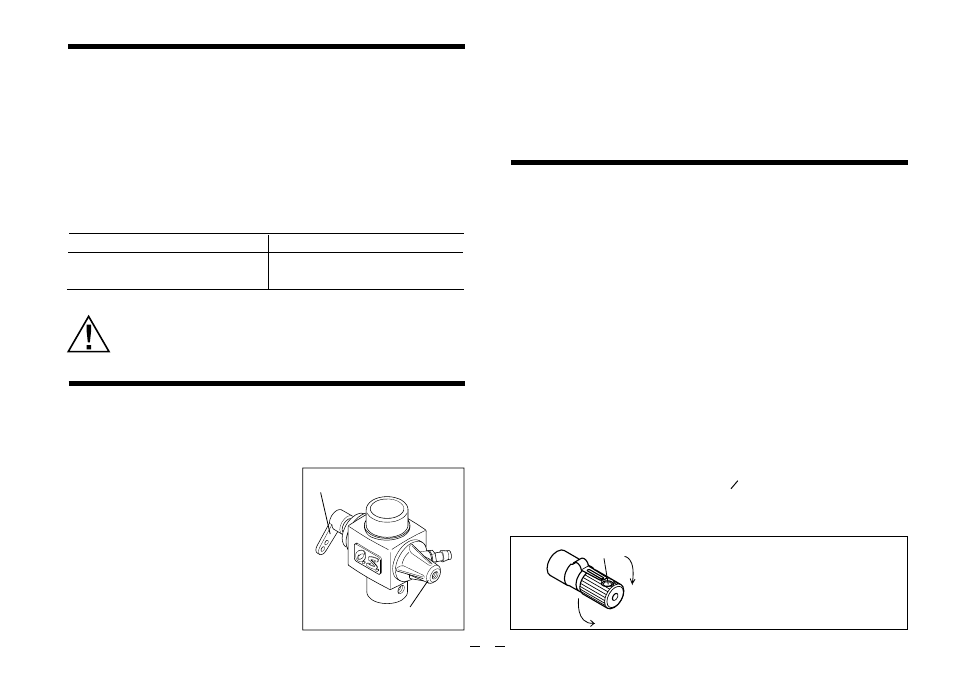

The Needle Valve

When set to produce maximum

power at full throttle, this

establishes the basic fuel/air

mixture strength. The correct

mixture is then maintained by the

carburettor's built-in automatic

mixture control system to cover

the engine's requirements at

reduced throttle settings.

Two mixture controls are provided on these engines.

Sport

Aerobatic

•

The Mixture Control Valve (carburettor)

This meters fuel flow at part-throttle and idling speeds to

ensure reliable operation as the throttle is opened and

closed. The Mixture Control Valve is factory set for the

approximate best result. First run the engine as received

and readjust the Mixture Control Screw only if necessary.

•

Throttle Lever

Mixtire Control Screw

STARTING

Install an appropriate propeller and tighten securely.

Ream the propeller boss to 9.6mm bore, then check that

the propeller is accurately balanced.

To facilitate electric starting, fit an spinner for centring the

rubber drive insert of the starter.

First tighten 17mm nut securely with a wrench, then tighten

14mm nut securely. Alternatively, a good quality spinner,

enclosing the propeller boss, may be used, but make sure

that it is of precision-made and sturdy construction so that

the spinner shell cannot loosen when the starter is used.

Close the throttle.

Fill the fuel tank. Do not allow fuel to overflow into the

silencer, otherwise the engine may become flooded and

difficult to start.

Check that the needle-valve is closed. (Do not overtighten.)

Now open the needle-valve 2-2 turns from the fully closed

position and temporarily set the throttle in the fully open

position.

2

1

1.

2.

3.

4.

Turn needle-valve clockwise to close

(for leaner mixture)

Turn needle-valve counter-clockwise to

open (for richer mixture)

Mark

Close

Open

9