Carburetor controls – O.S. Engines 91SX-H User Manual

Page 13

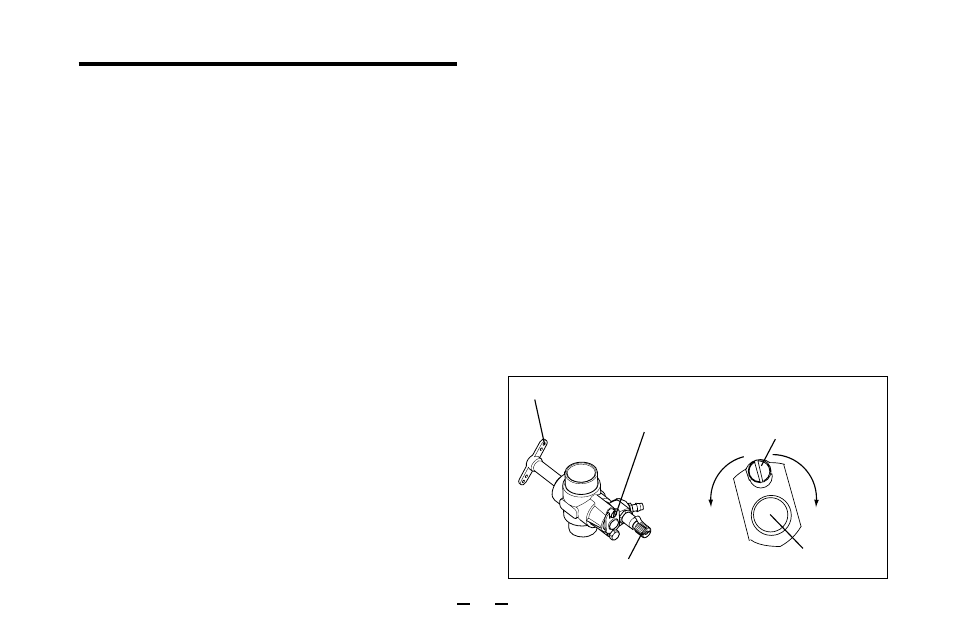

CARBURETOR CONTROLS

With a fixed-wing model, power failure is rarely a

serious threat to the safety of the aircraft since it can

usually glide down to a safe landing. In a helicopter,

on the other hand, it is vitally imporant that the engine

keeps running and that there is a quick and reliable

response to the throttle in order to ensure safe ascent

and descent of the model.

The Needle Valve:

When set to produce maximum power at full throttle,

this establishes the basic fuel/air mixture strength.

This is then maintained by the carburetor's

automatic mixture control system to cover the

engine's requirements at reduced throttle settings.

The Mixture Control Valve (Mixture ControlScrew):

For adjusting the mixture strength at part-throttle

and idling speeds, to obtain steady idling and

smooth acceleration to medium speeds. The Mixture

Control Valve has been factory set for the

approximate best result. First, run the engine as

received, and re-adjust the Mixture Control Valve

only when necessary.

Two adjustable controls are provided on this carburetor.

Needle Valve

Throttle Lever

Mixture Control Valve

(MIxture Control Screw)

•

•

BASIC POSITION OF MIXTURE CONTROL VALVE

(Mixture Control Screw)

Thick

Mixture Control Valve

MIxture Control Screw

Lean

As delivered, the Mixture Control Screw is positioned

at the center as shown in the sketch.

Mixture gets lean when the Mixture Control Screw is

turned right, while mixture gets rich when the Mixture

Control Screw is turned left.

With a model helicopter, adjustments vary with

combined various factors such as climatic conditions,

fuel, muffler, main rotor, weight of the model, gear

ratio, etc. Therefore, Mixture Control Screw position

varies with each model and set- up, and it is normal

if the Mixture Control Screw position is off center.

12